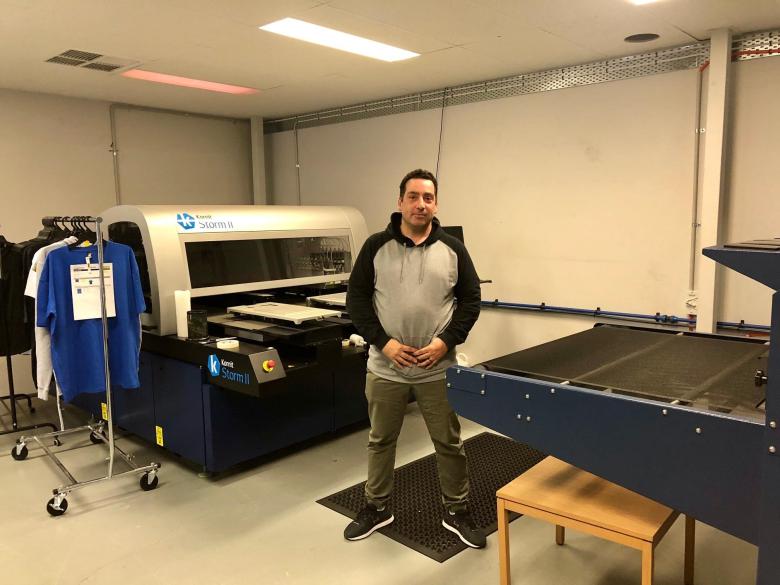

Sydney apparel printer Mark Yammin could not be happier with his new Israeli-made Kornit Storm 11 direct to garment printer which has allowed his business to expand without taking staff time away from other jobs.

Create Apparel, in Sydney’s west, began in 2002 as a supplier of sports clothing but has since added custom t-shirt printing to its repertoire.

The company had been supplying short run jobs with a smaller press but in order to achieve larger quantities and a higher quality product further investment was needed.

After checking out the products on offer, the decision was made to purchase the Kornit Storm 11 through Australian distributor Kissel & Wolf.

This press, installed in March this year, along with an Adelco industrial textile dryer has allowed Create Apparel to supply much larger orders of custom t-shirts, delivering a better deal and a superior product to customers.

“Before we were using a small printer and doing the work on a much smaller scale so this has put an end to that,” Yammin told ProPrint.

Crucial to the purchase decision was a press that did not require more than one person to run it.

“We wanted something where we could get a new system in and we wanted to expand but we didn’t want something that would drain our resources,” Yammin says.

“This is a one-man operation. One person can do all the printing at a high rate and that is the reason we went with this set up. The quality is also good.”

The Kornit produces 35 to 45 t-shirts per hour and Yammin says it has been quite easy to use with plenty of tech support from Kissel and Wolf.

Installing the new system has also freed up staff to continue with the sports apparel side of the business.

Even better the custom t-shirt business is also going well.

“We are doing so much work with it now. At first we were just finding our feet with it but it’s got a lot busier now,” Yammin says.

Tomas Lorenc, sales manager, digital equipment at Kissel and Wolf says the key point of difference with this direct to garment press is it involves just one step.

“It is the only solution in the market which can do direct to garment printing in one step because it has an integrated pre-treatment system,” Lorenc says.

“Any t-shirt that has to be printed needs to be pre-coated and with other technology the shirt has to be pre-coated separately so in this case the process is simplified.”

The chemistry of the inks is also different to other direct to garment presses meaning it is possible to print on fabrics other than cotton.

"Like with any capital equipment, the initial investment is a bit larger, but the customer is rewarded with high print volume capabilities and the lowest COP on the market," Lorenc says.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter