AGFA INVESTS IN CORE TECHNOLOGY

Agfa has a new high speed plate processor that can handle 15,000sqm of plates in a single bath life, three times the usual capacity. Agfa Oceiania managing director Mark Brindley says, “There is no water with the Arkana, we use a gum to wash out and prepare for press. The Energy Elite plates can print up to 600,000 sheets, which is what web offset printers in Australia need.” The show has also seen the launch of the company’s first LED Anapurna wide format printer, which says Brindley, offers lower running costs due to its significantly lower power consumption. At the high end, Agfa has positioned its Jeti Tauro, which is available in both three quarter automation and manual modes. Brindley says, “The automated mode adds not much more than 20 per cent to the price, so is well worth it, although printers can upgrade at a later stage if they want to.” The LED printers –the Anapurna H2500i, the Anapurna H2050i and Anapurna RTR3200i – come with air-cooled LED UV-curing as standard. Agfa says this enables energy saving and reduced running costs. The names of the printers denote their respective widths: the 2500i, 2.5m; the 2050i, 2.05m; and the 3200i, 3.2m with roll-to-roll. They all use six Konica Minolta print heads and print at up to 127sqm per hour in six colours: cyan, magenta, yellow, black, light magenta and white.

NEW BOXMAKER FROM BCS

UK manufacturer of quick-set box making machines, launched its latest corrugated boxmaker at drupa, the BCS Boxer. Making use of 35 years of industry experience, BCS has combined all of its box making knowledge and the latest technology to design what it says is its most compact and efficient machine to date. With a minimal footprint, no need for a compressed air supply, and attractive pricing, the new Boxer is designed to open up in-house box making to a whole new market. BCS says the user friendly push-button technology means perfectly sized, quick and easy boxes that are cheaper to produce and yet use less material. And because they fit better, they are cheaper to transport and give more protection which eliminates customer returns. With the addition of in-line digital printing, users can also print on boxes as they are being made.

BOBST BRINGS INNOVATION

Bobst, supplied by Ferrostaal in Australia, revealed it has a digital folding carton press already at two beta test sites in Germany and Switzerland, for the system it has co-developed with Kodak, and a further two at its headquarters. Carstern Wendler, managing director of Ferrostaal in Australia says, “Bobst is a conservative businesses, it has no need to rush into things, but is well down the track of bringing digital innovation to the market.” Digitally driven automation was a key feature of the Bobst line-up at drupa. Leading innovation in sheet-fed die-cutting and folding and gluing processes respectively are the completely new Mastercut 106 PER and Masterfold 110 A3, both of which offer higher running speeds, much faster make-readies, less waste, increased uptime, and technology that Bobst says makes zero-fault production achievable. These attributes also appear on the MasterfoilL 106 PR hot foil stamping press on show, which features a new module, Foil Unwinder+, that is making its drupa debut. This drupa also saw three web-fed world premieres from Bobst, confirming its focus on printing and converting and on displays, with a wide range of technologies designed to appeal to several market segments within the packaging industry. The M6 UV flexo press gives users access to the disruptive technology of Digital Flexo printing onto folding cartons and flexible packaging, the CL 750D compact laminator offers a way for converters to access new markets such as that for ultra-short run laminating, while Bobst says the MW 85F & MW 125F CI flexo presses offer new levels of flexible packaging print productivity. Bobst has also used drupa 2016 to announce the launch of three further flexible packaging presses.

CANON ZONES IN ON INKJET

Imaging giant Canon has motored into the cut sheet inkjet market with the launch of its i300 A3 printer. It uses Kyocera heads, with imaging taken from the ColorStream, while the paper path comes from Océ in Venlo. Tim Saleeba, general manager for production print at Canon Australia says, “The new Canon i300 will be available in Australia in about 12 months, and is designed to sit between toner based systems and roll fed inkjet. The quality matches toner and the productivity is high. It will be positioned as an affordable inkjet printer.” Canon has also shown a B2 sheetfed inkjet press, which it intends to have available the year after next. The new Océ ColorStream 6000 Chroma also launched at drupa, featuring a new ink flow to prevent nozzles from blocking when not in use. Also new, the latest version of its Arizona flatbed UV printer, the 2200 Series, and its new cut sheet toner printer the imagePress 10000VP. Other launches include the new ColorGrip option and new inks for the Océ VarioPrint i300 cutsheet inkjet press, enabling high quality colour reproduction on standard offset coated media; the first showing at a public exhibition of the Océ ImageStream 2400 continuous feed inkjet press. In 3D print offering, Canon has several systems working with the Materialise Magics workflow software following Canon’s recently announced partnership with Materialise. The Océ Arizona 2200 Series of UV flatbed printers reach speeds of 63.4sqmhr. They feature six colour Océ VariaDot grayscale printing technology; pneumatic registration pins, a new Onyx Thrive workflow solution couples with the Océ ProCut digital cutting system; and the addition of Light Cyan and Light Magenta.

CGS LAUNCHES HARD COPY FLEXO PROOFING

Designed for packaging proofing the Oris Flex Pack // Web software provides web-based hard copy and soft proofing in one package. At the heart of the application is a patented four-dimensional iterative color management software which, combined with a specially designed custom interface for Roland VersaCamm VS series printers, gives production flexibility for halftone and continuous tone proofing. All printer features, such as multi-pass and print-and-cut, are supported and the included Pantone colour libraries enable proofing of special colours. The Oris Flex Pack // Web software offers integrated soft proofing, proof certification and halftone support. Optionally available is a connection to the Esko Color Engine spot color database. Christof (Tommy) Thommessen, sales director at CGS says, “Flex Pack // Web is not only software, it includes a modified Roland DG printer which has an extended gamut with the addition of orange and green, and we can also print on plastics and films.” Local agents for CGS are DES and Ideal Solutions.

DURST INTO DIGITAL FOLDING CARTON

Durst launched the new Rho 130 SPC which, with a print speed of up to 9350sqm per hour, which it says offers the industrial productivity needed to transform the packaging sector towards digital technology.

Alongside the more cost-efficient production of shelving and sales packaging in small and medium-sized job runs, the Rho 130 SPC also supports sampling, customizations and versioning – directly and without setup costs. With the development of a non-hazardous ink system based on Durst Water Technology, Durst is also already addressing the future directives for sustainable packaging products in the food retail sector.

The Rho 130 SPC is based on the latest generation of single-pass printing systems which Durst is already using in the label printing segment, for instance, with the Tau 330. This single-pass UV inkjet label printing system alone has been installed for 60 clients within the space of a year.

Its success is based on the configuration and automation options that allow end-to-end production and, with low-migration UV inks, also support their use on primary packaging.

Durst presented the Tau 330 in combination with a laser finishing system (LFS) and providing information about the new Tau 330E standalone model which, with a pigment ink system, offers a cost-effective gateway to digital production.

ESKO AIMS FOR SIMPLIFICATION

Packaging production developer Esko is following a strategy of simplification, and teamed up with X-Rite, Pantone and Enfocus to show how the brands work together for the lifecycle of a product. The company has upgraded its software suite, now called Esko Software Platform, and claims to have the largest software as a service (SaaS) platform in packaging with 25 global brands, more than 30,000 users globally and more than half a million uploaded assets. The new version is clearer and mobile-optimised and was shown for the first time at drupa. Esko Software Platform can be used on-site or in the cloud and Esko is also launching Esko Share And Approve Web Centre for sharing, annotation and approval online, which it said would ensure faster approval cycles. WebCenter is packaging management solution that streamlines activities from specification and design through production. Users share files with all stakeholders for approval and collaboration. In the new version, they are able to view 3D designs, including transparency and print finishing effects, using a standard web browser on a desktop computer or mobile device. On display was a new integrated flexo imaging and exposing solution, the CDI Crystal 5080 XPS. According to Esko this new flexo platemaking solution delivers a 68 per cent reduction in operator time for platemaking; 50 per cent reduction in operator training time; and 74 per cent faster time to plate.

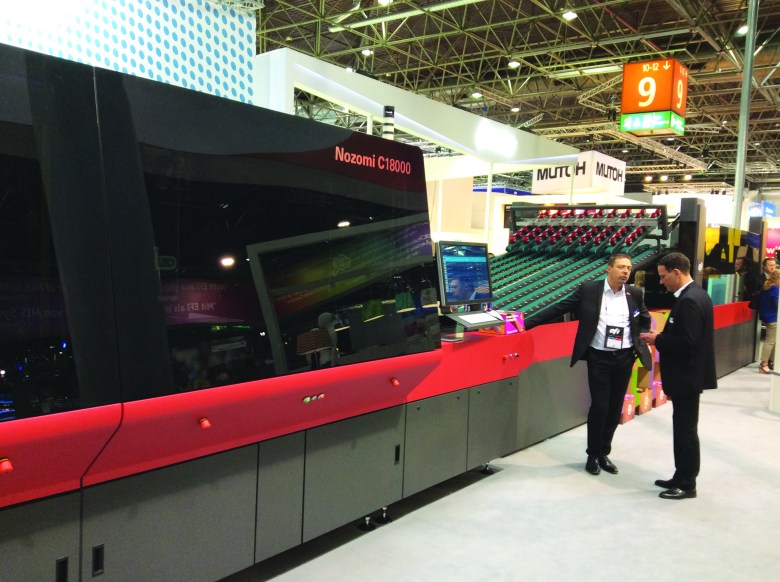

EFI MAKES MAJOR PLAY FOR FOLDING CARTON

EFI launched the new EFI Nozomi digital folding carton press; and a new ink set, AquaEndure. EFI’s biggest inkjet product development, the Nozomi, is a 1.8m wide 30m long single-pass LED inkjet sheetfed direct-to-corrugated board press printing at 75mpm, producing up to 9,000 80cmx60cm boards per hour using a double-lane printing feature. It prints up to seven colours, including white, at a 360x720dpi, handling materials up to 1.8x3m and thicknesses up to triple-wall board – at full rated speeds, according to EFI. Board substrates include traditional Kemi, model, bleach, and kraft materials. EFI says packaging produced with the press is fully industry certified for repulpability and recyclability. EFI adds that, when commercially available in 2017 it will offer a lower acquisition cost compared to digital inkjet corrugated presses currently on the market. The AquaEndure inkjet technology, EFI’s water-based inkjet platform, targets customers making applications in areas like wall coverings, wraps, and flexible signage. EFI says AquaEndure inks cure using much less heat, have no odour, and can adhere to virtually any substrate. The new Fiery XB DFE platform for ultrahigh-speed inkjet presses, specifically the new machines from Canon, EFI, Landa, and Fuji Xerox, offers a scalable DFE platform using Fiery software. Other EFI innovations included the cloud-based Fiery Navigator.

EPSON BROADENS APPLICATIONS

Moving its Precision Core technology into new applications, Epson continues its rapid growth from manufacturing its proofing devices into multiple new sectors. In its Sign and Display zone, Epson had its latest range of wide-format SureColour SC-S signage printers and SC-F dye-sublimation printers producing a selection of signage, display and décor products on a variety of substrates. The SureColor SC-S Series gives a choice of three printers from 4-11 colours (including red, orange, white and metallic silver) and productivity up to 95.3sqm/hr. The new Epson Control Dashboard gives users online access to over 200 different media profiles for automatic set up. In dye sublimation, Epson has the latest range of SureColor SC-F models using UltraChrome DS ink. The Label zone featured Epson’s SurePress digital label presses: the single-pass SurePress L-6034VW; the seven-colour SurePress L-4033AW; the ColorWorks C7500, desktop label printer; and the LabelWorks LW-Z900 for industrial and construction use. The Print Shop zone shows a range of desktop-based production printers from the SureColor SC-F2000 direct-to-garment printer to the SureLab D700 inkjet printer; the aqueous SureColor SC-P wide format printers; the 64-inch 10-colour SC-P20000; and the the 44-inch SureColor SC-P10000. In its Prepress zone, Epson had its latest SureColor 24-inch SC-P7000 and 44-inch SC-P9000 printers on show.

VERSATILE FINISHING FROM FERAG

Swiss finishing company Ferag launched two major innovations at drupa 2016; one an inserting line than can insert personalised brochures into newspapers, and the One2out flexible inserting system that allows single, double or parallel processing. Daniel Fasser, managing director Ferag Australia, points out that the hyper targeted line will not appear here for a while, but says, “The One2out will have great appeal, it will address issues where inserting numbers change effortlessly and so will be great efficiencies.” The modular One2Out line, for processing and inserting supplements and advertising brochures, has two strands connected by a loop. It can run as a big production with up to 41 hoppers or as two small parallel processes with up to 21 hoppers per strand. Running strands A+B with 41 hoppers, it processes 20,000 copies per hour. In parallel mode, with two times 21 hoppers, line output is doubled to a total of 40,000 copies per hour. At the final stage of the collecting process, the PostStack and SmartStrap machines tie the collections into stable bundles. Ferag says it has optimised these for insert-in-insert processing. The company says that customers who want to get the most out of their One2Out system can use the Optimiser to load the ideal production strategy in seconds. Ferag has become the number one supplier to the newspaper sector in Australia and believes its new solutions will offer new revenue to publishers.

FUJIFILM RAMPS UP PRODUCTIVITY

Fujifilm announced a host of innovations at drupa including upgrades to its XMF workflow; a new processless plate – the Superia – designed for UV inks; and a new flexo plate the Flenex FW, which has no chemicals. Lindsay Barnes, managing director of Fujifilm’s graphics division in Australia says, “The new plate is a win-win. It is 50 per cent faster, offers a higher quality, and is eco-friendly. The quality improvement comes because the dots are flat top, rather than conical.” The company launched the new Inca Onset X series, which prints up to 900sqm per hour in X3 mode, which has CMYK times three. Barnes says printers can upgrade with the same piece of hardware form the X1, through X2 to the X3. He says, “Component upgrading is an efficient way to increase your capacity as your business grows without replacing entire production units.” Fujifilm also launched the Uvistar Hybrid 320, which is designed to print both roll-to-roll and flatbed and comes with a 3.5m width. Barnes says, “For commercial printers looking to get into the wide format market it is the ideal solution, because it provides the flexibility to print any kind of job efficiently.” It prints eight colour plus white. Fujifilm also says it has produced the means for printers to operate lights out production plants, thanks to a partnership with US developer Epac, using its so-called 5D printing, a non-linear automated production system.

[Related: drupa 2016: cloud, inkjet and process digitisation]

FUJI XEROX MAKES INKJET MOVE

The world’s biggest toner based digital print system developer Xerox has launched into inkjet printing, with a new B3 sheetfed inkjet printer and a new webfed inkjet printer. The company says inkjet offers new possibilities to printers to capture more of the pages not printed digitally. It will release the cut sheet Brenva towards the end of this year, with the continuous feed Trivor ready for orders. The Brenva opens up possibilities for the transactional, light direct mail and book markets. Xerox says, with the Trivor 2400, print shops can move to broader application areas such as catalogues, magazines and colour books. With Müller Martini, Xerox has a new end-to-end workflow solution for personalised catalogue production on the Trivor 2400, automating the entire workflow process and customised content to meet tailored requests from customers. Xerox has begun making a major play for packaging, co-developing a sheetfed folding carton press with KBA, the VariJet 106, a 4500sph seven colour press. Xerox also launched its new High Fusion Ink – new ink that enables inkjet printing on traditional offset coated stocks eliminating the need for pre or post paper treatment, a clear toner for the fifth station of the Xerox iGen5 Press, the Xerox Direct to Object Inkjet Printer for inkjet printing on 3D objects as small as bottle caps and as large as football helmets and shoes, eliminating the need for labels in many retail and manufacturing applications.

GALLUS LAUNCHES DIGITAL LABELFIRE

Gallus has launched its inkjet digital press the Labelfire, which uses the Fujifilm technology that parent Heidelberg has on its Primefire digital folding carton press. Heidleberg’s biggest shareholder and former Gallus owner Ferdinand Ruesch said the new press was three times faster than anything else on the market. He says, “The speed is tremendous, but that is only part of the story. It is its inline capabilities that also set the Labelfire apart. The Labelfire will rip, print, convert, embellish and finish in one pass. It can have multiple embellishing options including foiling and flexo both of them upstream or downstream of the print. And for us the press is only part of the solution, label printing is industrial printing, a full digital end to end solution is where label printers will win, and we alone are able to deliver this. For the printer this means just one point of contact, rather than dealing with multiple vendors.” Gallus aims to be number one in the digital label print market with the Labelfire, and believes its speed, quality, and inline production will enable it to overtake HP and Xeikon, although ‘not immediately.’ The Labelfire is based on the ECS granite press from Gallus, of which more than 400 have been sold around the world. James Rodden, general manager of Gallus Australia says, “There is no doubt that for Australian label printers looking for short run or variable data label printing the Labelfire will be the answer.”

HEIDELBERG TO DEVELOP SELF PRINTING PRESSES

The world’s biggest press manufacturer Heidelberg says it will develop driverless presses which will double print productivity. CEO Dr Gerold Linzbach told the world’s media this drupa represented the ‘new birth’ of Heidelberg into a world where integration was key, and where digitisation of process would drive the industry forward. The company aims to make printing presses self managing units, where everything from production planning, to consumables ordering, to predictive maintenance are all generated from the press itself. It calls this its Push to Stop concept, with the presses themselves taking over all aspects of the production. The Push to Stop concept is available for the new generation Speedmaster, covering the series XL 75, CX/SX 102, XL 106 and XL 145/162, which are equipped with the Prinect Press Center XL 2, the Wallscreen XL, and AutoPlate Pro or AutoPlate XL 2 and Inpress Control 2 automation components. Heidelberg launched its Primefire 106, the world’s first digital inkjet sheetfed B1 press, developed in co-operation with Fujifilm. Heidelberg says the Primefire 106 enables packaging printers in particular to take the first step in developing new areas of business, for example with the production of variable or personalised packaging. The digital printing system offers a number of highlights, including the highest quality of 1,200 x 1,200 dpi at a printing speed of up to 2,500sph.

AUTOMATION COMING FROM HORIZON

Visitors to the Horizon stand at drupa saw some impressive finishing lines for high speed roll fed finishing, with the Japanese manufacturer teaming up with Hunkeler and Tecnau to create complete solutions. The finishing lines can accommodate different book sizes, with bar codes telling the individual unit, for instance the Horizon HT-1000 three knife trimmer, which size to cut, with the trimmer then automatically setting itself, there is no human activity. Bernie Robinson says, “It can produce 1000 books an hour, all different sizes if required with no let-up in the speed of the system.” Also new from Horizon is the SmartSlitter, which works with A3 sheets and can cut and perforate either left to right, right to left or top to bottom. Robinson says, “For business card printers it works really well, it can cut 21 cards out of an SRA3 sheet at a rate of 3,400 sheets an hour. It will perforate at a similar speed, and again it is all controlled by a barcode with the machine setting itself.” Among its new products Horizon launched the new BQ-480 Variable 4 Clamp Binder, a four clamp Perfect Binder that the company says features the quickest setand superior quality. Robinson says it is 50 per cent faster to make ready, and can print runs as short as one, again with a bar code setting the system. It will produce up to 800 books per hour in variable thickness book production.

HP INTO END TO END SOLUTIONS

The biggest and busiest stand at the show was Hall 17, where HP has booked out the entire 6,200sqm and had 56 different printing solutions on display. Phillip Rennell, sales and marketing director at Australian and New Zealand distributor Currie Group, says, “Printers coming from Australia and New Zealand are embracing the complete solutions that HP is demonstrating at this drupa. It is no longer just about what the machine will do, it is about how to optimise productivity, with software, integration and automation playing a big part in that. HP is moving forward, as is the print industry, developing ways to produce more, and more efficiently. Today for HP, it is not only about the conversion of offset, it is about maximising utilisation and applications.” Among the new launches is the HP Indigo 12000 B2 press, which Rennell expects to hit our shores next year. It has several enhancements to the existing HP Indigo 10000; however the 10000 can be upgraded in the field to the 12000. Renell says, “HP is determined to protect a printer’s investment. We have an upgrade strategy that does not involve fork lift trucks.” HP also launched its PrintOS at drupa, which it describes as an operating system for a business. Rennell says, “It is a platform from which our customers will be able to draw on knowledge and software as they need or want it. Printers will be production centres, and they will be able to use any number of a host of apps as they need them to help in their business.” Two innovations to watch out for in the future include the new HP PageWide C500 Press, a flexible industrial post-print corrugated solution powered by HP PageWide Technology, and the new HP Indigo Digital Combination Press, enabling HP Indigo print and digital embellishments in a single pass. HP says the new HP PageWide C500 Press introduces a versatile, offset-quality cost effective solution for corrugated direct-to-board printing. For combination labels’ production, the HP Indigo Digital Combination Press concept will incorporate HP Indigo print and digital embellishments in one press, creating a fully-digital, single-pass solution to deliver high-value labels and packaging production. Developed in alliance with JetFX, HP says it will enable streamlined production of digital spot and tactile varnishes, digital foils, as well as embellishments.

KBA JOINS WITH XEROX

KBA and Xerox are currently co-developing a B1 sheetfed digital folding carton press, the VariJet 106, which the companies say will take them into leadership in this new market sector. The VariJet 106 will print inkjet in up to seven colours, it will have a white preprint unit in front of the printing units, it will have cold foiling option, it will be able to print screen and offset inline if required, and will have double coating and inline die cutting if specified. It lists the resulting benefits and advantages as: flexibly configurable press with up to seven colours for individual demand; print speed in B1 format of up to 4,500sph with a print resolution of 1440 dpi; handles substrates 0.2 to 0.6mm with a 40in transport belt for precise sheet travel There are two full machines currently in the KBA labs; delivery of the first machines is slated for next year. On its 3,000sqm stand, KBA had a plethora of solutions including four Rapida sheetfed offset presses from half rotary die-cutter; the re-designed high-volume digital RotaJet L series; the NEO XD LR web press from KBA-Flexotecnica; a laser coding and separating system from KBA-Metronic; and solutions relating to service and workflow. KBA is making parallel investments in offset and digital.

KODAK LAUNCHES 20 NEW SOLUTIONS

Kodak opened drupa with a blizzard of new solutions and upgrades, aiming to build on its US$1.1bn Graphic Communications business. Visitors to its drupa stand saw more than 20 new products on the booth, including a new Nexpress the ZX3900, a new version of its Sonora plate, a new aqueous narrow web inkjet system XGV, and Ultrastream developments. Kodak drupa launches include both the NexPress ZX3900 and ZX3300 digital production colour presses, the NexPress Opaque White Dry Ink, and in the packaging sector the Flexcel NX System ‘16, an integrated flexo plate production system including workflow, plates and imager. Kodak also debuted its Ultrastream technology, its high quality inkjet printing, with a 1800dpi resolution, although this will not be ready for commercial launch for three years. Built on its continuous inkjet Stream technology Kodak it will according to Kodak ‘move production inkjet into the mainstream of commercial printing and packaging’. Kodak announced new OEM partnerships with manroland Web Systems and Matti Technology to integrate Prosper Stream onto their systems. Kodak is launching two plates that it says will set new levels of on-press performance for print service providers. The Sonora UV Process Free Plate is a new plate designed to allow printers using UV, including the newer low-energy UV presses, to achieve higher run lengths than with any other process free plate available today. The Kodak Sword Max Thermal Plate will feature the new, patented Advanced Resin Technology (ART), which delivers high-performance features for printers facing challenging conditions.

KOMORI INTO DIGITAL B2 AND B1

On the Komori stand visitors saw the first fruits of the company’s launch into digital, with the Impremia S29 B2 sheetfed press co-developed with Konica Minolta and the Impremia NS40 B1 sheetfed press co-developed with Landa. Komori – supplied in Australia by Ferrostaal – had as its main theme Open New Pages. This drupa marked the start of general availability of the Impremia IS29, Komori’s inkjet UV printing system, which is capable of printing on a wide range of stocks. By taking advantage of UV inkjet characteristics, this system is aimed at commercial print applications, and also package printing. Also on the stand was the B1-size Impremia NS40 digital printing system that uses the new nanotechnology under license from Landa Corp. This new product will perform high-speed printing at 6,500 sheets per hour. Komori though is still focused on its core technology, under its OffsetOnDemand banner, with the Lithrone GX40RP on the stand. It was equipped with the latest Komori technologies to provide the ultimate short makeready by using parallel control and high productivity up to 18,000 sheets per hour. The GX40RP requires no flipping of the sheet, maximising print area, Komori says this makes it an ideal solution for the increasing demand for package printing with double-sided multi-colour printing. Komori’s popular Lithrone GX40 with coater on the stand demonstrated advanced printing control and a high-precision print inspection system that enhances high-speed package printing and specialty printing. All offset presses on the show floor were equipped with Komori’s proprietary H-UV innovative curing system and demonstrated using K-Supply H-UV ink. Making its debut in Düsseldorf was the new Lithrone G29 29˝ offset printing press. With a renovated design and equipped with the latest in systems and automated devices, it provides short makeready and reduced total lead times. Another compact press introduced at drupa 2016 is the new Lithrone G37, for producing an A1 maximum sheet size.

KONICA DIVES INTO DIGITAL FOLDING CARTON

Konica Minolta sprang a major surprise at drupa 2016, revealing that it is developing the KM-C, a B1 format sheetfed UV inkjet digital press targeted at the commercial print and packaging sectors, making it the first printing system developed from top to bottom by Konica Minolta. Also launching its B2 sheetfed inkjet press, now known as the AccurioJet KM-1, Konica saw crowds packing the demonstration areas to gain an understanding of its capabilities. Presented as a technology showcase prototype to gauge interest, the Konica Minolta KM-C lifts technology from the AccurioJet KM-1, giving it image quality at 1200 x 1200dpi resolution, as well as colour stability, with an inline sensor and image correction and the ability to print on a wide range of paper substrates without pre-coating. The company says the flatbed sheet-feeding platform that it designed for the KM-C, enables easy processing of materials such as cardboard and micro flute. It can easily handle paper thicknesses between 0.3 and 1.2mm and can print up to 2200 B1 sheets per hour with a maximum paper size of 760 x 1,060 mm. Setting its sights on a leadership role in the industrial printing market, Konica Minolta has focused on key industrial applications such as label and packaging, hence the development of the AccurioJet KM-1 B2+ sheet-fed UV inkjet press. Konica Minolta says its AccurioJet KM-1, in combination with MGI’s Jetvarnish, shows visitors a wide range of benefits such as hybrid printing with the integration of KM-1 into existing offset processes, duplex printing and larger sheet sizes, as well as printing on packaging board, lightweight papers and textured stock.

LANDA SHOWS NANOGRAPHY

Benny Landa opened drupa with a flurry of announcements and a futuristic presentation that he says demonstrates the transition of the company and its Nanography technology from a proof-of-concept, unveiled at drupa 2012, to what it says is a robust line of presses that will address all major print segments. There were four models on show, the B1 sheetfed S10 for folding carton and POP applications, the B1 sheetfed perfecting S10P for commercial print, the W10 for flexible packaging and the new Landa W10P, which is metre-wide (41“) perfecting press with two printing engines. Designed for the publishing, catalogue and direct mail segments, it prints at 200 meters per minute on a variety of coated and uncoated papers, light boards and metallic substrates. Landa says the B1 sheetfed presses will run at 13,000 sheets an hour. The so-called cockpit has been redesigned since the last show to sit at the delivery end of the presses. At drupa the presses were printing at full speed. Landa says the first beta presses will go into the field next year, with commercialisation to follow. The company says its order book was bulging to the tune of $650m during drupa, with four Australian printers in the mix. The Landa nano presses promise offset quality at offset speed on offset stock, but with the digital benefits of no makeready, no plates, and variable data printing. They use microscopic ink particles transferred onto stock via a blanket. Landa is promising the lowest cost per page with his nano presses. Landa has partnerships with Esko for its packaging presses and Kodak Prinergy. Landa also launched its newest technology, Nano-Metallography, a zero-waste metallisation process that the company says will halve the cost of metallised (foil) printing.

EVOLUTION AT MANROLAND IN B1

The manroland sheetfed drupa stand had the new Roland 700 Evolution as its centrepoint, which the company says will exceed the needs of commercial and packaging printers. The new press is an upgrade of the Evolution launched 18 months ago and comes with a brand new operating concept, inline everything including cold foiling and a choice of drying systems including LED UV. Steve Dunwell, managing director of manroland Australasia says, “The new Roland 700 Evolution offers unparalleled efficiencies combined with manroland’s unbeatable print quality. “We are targeting packaging printers and top end commercial printers who need to know that they will be capable of producing the best print available.” The Roland 700 Evolution comes with a new Press Pilot intuitive control system, a new feeder, new drive technology, and can be made ready fully automatically in less than five minutes. The new press can also incorporate inkjet heads for variable data. Steve Dunwell says that the company’s successful service programme which has been implemented in its web business will now be available in sheetfed too. This sees manroland manage a proactive programme which the company says can deliver significant productivity uplift, up to 20 per cent or more. On the web side manroland has developed its folding superstructures to work with high speed inkjet webs.

MGI METEOR UNLIMITED COLORS

French developer MGI launched a digital press with Inline Hot Foiling that features the exclusive Authentication Hologram Digital Printing (AHDP) System. According to the company the integration of MGI Digital Presses and iFoil digital hot foiling technology creates a new colour spectrum with the reflective light qualities of metallic coloured foils. The foil can be overprinted with the CMYK toner to create diverse colour tones and sparkling effects. A virtually unlimited number of colours can be produced. The Meteor Unlimited Colors product series creates effects on uncoated and textured papers, as well as on coated and offset papers. AHDP, an MGI patented system, produces on-demand holographic imprints with Meteor Unlimited Colors presses, specially-formulated toner and foil films. The company says the digital holographic effects offer customised security authentication options at a fraction of traditional costs. This anti-counterfeiting method is now economically accessible without the need of expensive dies and lengthy tooling processes. AHDP also works in conjunction with Variable Data Printing (VDP) to create document identification applications. With multiple different Digital Press configurations available according to specification, the Meteor Unlimited Colors product series can support paper sizes up to 330 x 1200mm, paper weight up to 400gsm and envelopes.

MÜLLER MARTINI LOOKS TO FULL AUTOMATION

Müller Martini says it is heading for Finishing 4.0 with the postpress developer bringing a host of highly automated systems to the show. Included among these, the Infinitrim will produce books of infinitely different sizes automatically with no let-up in speed. It also launches its SigmaLIne with Connex which it calls a fully integrated line to finish industrial inkjet. The touchless production of products includes a personalised educational book – a job with fully variable content produced using three different systems, from the roll to the finished book; and personalised book blocks, each with a completely different page count, size, book thickness and content, all produced in sequence in runs of one copy using the SigmaLine digital book production system, which allows for VDP production thanks to three new modules of the Connex process and data management system. Müller Martini then shows how to perfect bind books in sequence using the Vareo, which it describes as the first perfect binder at which all three clamps have their own servo motor and are individually driven, representing a technological revolution. The InfiniTrim then performs the three-sided trimming of books that vary from product to product. Conventional three-knife trimmers have a cutting table and pressing pad, which have to be manually changed in the case of size changeovers. The InfiniTrim allows three-knife trimming in runs of one copy. World premieres of new innovations and updates included the Primera MC saddle stitcher, the Alegro Digital perfect binder, the InfiniTrim three-knife trimmer, the Ventura MC Digital thread sewing machine, three new SigmaLine functions, the open Connex architecture. The company says the new Primera MC saddle stitcher enables extremely short processing times and owners can upgrade to the Primera MC Digital for processing digitally printed products. The Primera MC has a new vertical pile feeder. Operators can feed it from the front instead of from the top. It stands around 20cm lower than the flat pile feeder and provides a loading capacity of the signatures of around 40 cm.

RICOH TARGETS COMMERCIAL WITH VC60000

Launched at the show was the Ricoh VC60000 high speed inkjet printer, which with new printheads and new inks is targeting commercial printers. Henryk Kraszewski, senior product and marketing manager – Production Print at Ricoh says, “The VC60000 takes Ricoh’s high speed web to the next level. In addition to its ability to print transactional, transpromo, book and direct mail it can now print commercial jobs.” The VC60000 prints 150 metres a minute, which translates to 120,000A4 images an hour, at 1200x1200dpi on stocks between 40-250gsm, both coated and uncoated, from more than 200 types approved by Ricoh and available from merchants. In its cutsheet portfolio, Ricoh Pro C7100 series, visitors to drupa – and those that were on a live feed back to Australia – saw the evolving capabilities of the fifth station on the printer. It is already capable of accommodating white ink and clear spot coating, drupa saw a neon yellow security ink printed. A new digital front end print server – R-61/R-61A – will be launched for the Ricoh Pro C9100 and Ricoh Pro C7100 series of sheetfed colour presses, and which will also work with the major workflow software for offset presses. TotalFlow Print Server R-61/R-61A is designed to be compatible with major prepress workflow software for offset printing by enabling the same user interface to be used for offset and digital workflows. It is compatible with Prinect, developed by Heidelberg, Prinergy from Kodak, Agfa’s Apogee and Equios from Screen.

RMGT TO LAUNCH 8000SPH DIGITAL B2

The newly rebranded RMGT (formerly Ryobi and Mitsubishi) aims to launch an 8000sph B2 digital press to market early next year. If it does so, it will be three times faster than the current crop of B2 digital presses.The DP7, marketed as an offset digital press, uses a liquid toner and electro-photographic technology. Co-developed with Miyakoshi and built on a RMGT 920 chassis the press will initially be offered in a four colour version. However Bernard Cheong, managing director of distributor Cyber Australia, says, “In theory any configuration that is available on the 920 series will be available with the DP7.” The drupa demonstration saw it print three jobs of 30 sheets each with no downtime at all; makeready is zero. It then printed a dozen copies of a six page calendar with cover in sequence. RMGT says the 6000sph version will print three 200 sheet jobs in six minutes, aiming for offset quality print at 1200x1200dpi. The company intends to make the DP7 available from next year. Meanwhile the conventional B2 RMGT 9 press has a new feeder from Mitsubishi; a new ink train; a new inspection system with up to 10 cameras; and it now numbers every sheet with an inkjet coder for ease of reference if a sheet needs to be removed. This A1-size eight-colour convertible perfecting press has two LED-UV curing units, one over the perfecting device and the other at the delivery section, to enable one-pass instant-curing perfecting. Equipped with a Smart-RPC fully automatic simultaneous plate changer, the press on exhibit also has a PQS inline printing quality control system for controlling the printing quality of both sides of the printed sheets during perfecting. Greg Knight, general manager at Cyber Australia says, “The RMGT 9 is leading the market. With its LED technology and its A1 size available in any configuration, allied with these latest developments and a price point lower than a B1 press it is proving to be a popular choice with Australian printers.”

SCODIX MAKES B1 MOVE

Scodix says it is unlocking new enhancement and profit-generating opportunities for the folding carton market with the B1 E106 press launch. The Scodix E106 is a digital press delivering enhancement solutions for printers in the packaging sector. Running at up to 4,000sph Scodix says the press makes medium to short run lengths viable that were previously unachievable. Bernie Robinson, managing director Currie Group, the Scodix Australian and New Zealand distributor says, “Print embellishments provide an opportunity for converters to add value to products, when there is often little scope to do this elsewhere in the converting process. As average run lengths decrease, Scodix digital enhancement presses – with no tooling costs and next to no set-up –become an undeniably attractive option to replace analogue equipment. Converters investing in the Scodix E106 will be able to offer shorter run lengths profitably, new products, enter new markets and fundamentally, clinch a competitive edge in tough market conditions with value-added services that empower brands.” Delivering multiple print enhancements in one versatile technology platform, the Scodix E106 press delivers effects including Scodix Sense, Scodix Spot, Scodix Braille, Scodix Digital Embossing, Scodix Variable Data finishes and Scodix Foil, all in a single press. The digital enhancement press is proficient with a range of substrates.

SCREEN INTEGRATING IMAGING FOR INNOVATION

Most of the interest on the stand was for the flatbed Truepress 3200 HS UVII high speed UV printer, which has had a 20 per cent uplift in speed to 184sqm per hour in flatbed mode, or 230sqm per hour in roll to roll version. Screen managing director Peter Scott says, “The new Truepress 3200 is a robust industrial print system that is proving particular popular for POS printers. Its speed and quality set it apart; its multi-pass technology means it can print down to 2pt type.” The company also launched new B1 and B2 platesetters. The B1 will be available through WRH, Fujifilm, Screen itself, and rebadged by Agfa. It can produce up to 70 plates an hour, while the B2 can produce up to 33 plates an hour. Screen has developed a new ink for its high speed roll-to-roll inkjet printer, the Truepress Jet520HD, which can be printed directly on coated paper for offset printing. The new ink works with a wide variety of paper such as general coated paper, inkjet pure paper and plain paper. The images are close to that of offset printing and it is expected to enter the genuine commercial printing industry as an inkjet printer. Scott says, “The Truepress Jet520HD is for top quality printing, and is sure to make an impact in Australia.” The company launched a new version of its inkjet web 520 Truepress Jet, of which more than 1000 have been installed around the world. This one is the 520NX, with an increased speed of 150 metres a minute and a 600x1200resolution.

XEIKON LAUNCHES LIQUID TONER TRILLIUM PRESS

The Xeikon Trillium One took centrestage on the stand. A reel to reel liquid toner press, it can print 60mpm at 1200dpi. Xeikon also launched the 9600, a 195 pages a minute 1200dpi printer, that it calls the little brother of the successful 9800, which can print five over five and, says Xeikon, it comes with lower running costs. The company has also launched the FDU flatbed die cutting unit, which it says completes the folding carton suite. Xeikon also ran its CX3 with Fusion Technology, the end to end platform for one pass label production. Wim Maes, chief executive at Xeikon, says the Trillium One, slated for availability in Q2 next year, targets the commercial print market or for printers with multiple toner machines who want to simplify production. The Trillium One four-colour press at drupa 2016, has a print width of 500mm; high resolution imaging heads, and toner particle size of less than two microns. Maes says it combines cost-effectiveness, high quality, and speed. Xeikon calls it the missing link in the industry for high volume direct marketing materials and publishing such as catalogues. Xeikon says its toner capabilities, as part of production areas focused on labels, folding cartons and document and commercial printing, include its own-developed Tonnik, a liquid toner developed for Trillium One. The company says that Tonnik combines the advantages of dry toner in a liquid format.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter