In order to accelerate the growth of the global inkjet business, Fujifilm Imaging Colorants (FFIC) Inc. (a US subsidiary of Fujifilm Corporation), has revealed that it will soon construct a new production plant for pigment dispersions, which is a colorant for water-based pigment inkjet inks.

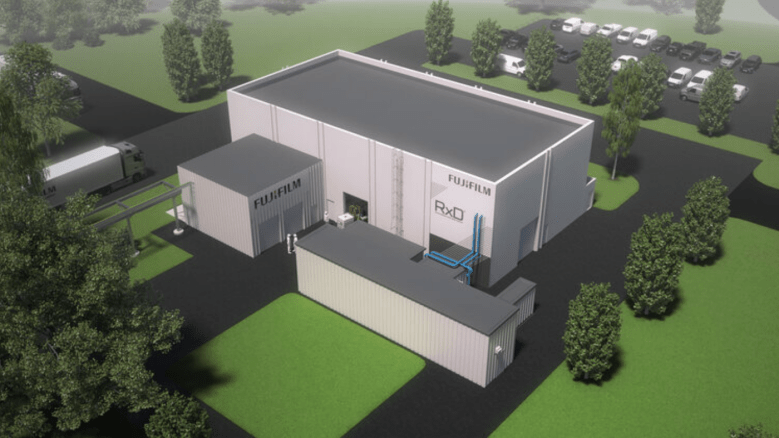

According to the company, the construction is expected to start in April and is scheduled for completion by 2022. Fujifilm Imaging Colorants said the investment for this construction is approximately US$19 million.

Fujifilm said by adding the new production plant for pigment dispersions (the main colorant in water-based pigment inkjet inks), it will be able to produce consistent, fully-featured water-based pigment inkjet inks built with its own core dispersion technology.

Fujifilm’s pigment dispersions are based on its RxD (Reactive Dispersant) technology, which cross-links polymer dispersants adsorbed on the pigment particles.

The dispersant prevents desorption from the pigment, aiming to create a very stable dispersion. This technology makes RxD dispersions suitable for multiple applications as they enable the design of stable ink formulations that meet demanding performance requirements.

Fujifilm uses RxD dispersions not only for its own inks, but also supplies to ink manufacturers around the world, and they are used in many water-based pigment inkjet inks.

Currently, the development and manufacture of pigment dispersions using RxD technology is limited to Fujifilm Imaging Colorants Ltd. in the UK. In the establishment of a new dispersion plant at FFIC Inc. in the US, Fujifilm said it will continue to ensure the production of the highest quality products and strengthen global supply capacity to meet the future needs of the growing industrial inkjet market.

FFIC Inc. president and chief operating officer Ian Wilkinson said inkjet technology has the capability to deliver fast, versatile, print production at short or long run-lengths with variable data.

“Applications for inkjet are expanding into industrial fields such as packaging printing in addition to commercial and publishing printing. In particular, there is a growing need to use water-based pigment inkjet inks, which have low environmental impact and potential to meet requirements for food packaging safety compliance,” he said.

“RxD is a key technology for current and next-generation water-based inkjet inks. Expansion of our manufacturing capacity is part of a commitment to ensure we can meet increasing demand to support our global customer base. We are already manufacturing a very high-quality, high-purity product in the UK.

“In this venture, we are using the design and project management expertise of our UK team to execute this project in the US. This, alongside expert knowledge, technology and processes will ensure that we manufacture RxD dispersions to the same exceptional standard across both sites.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter