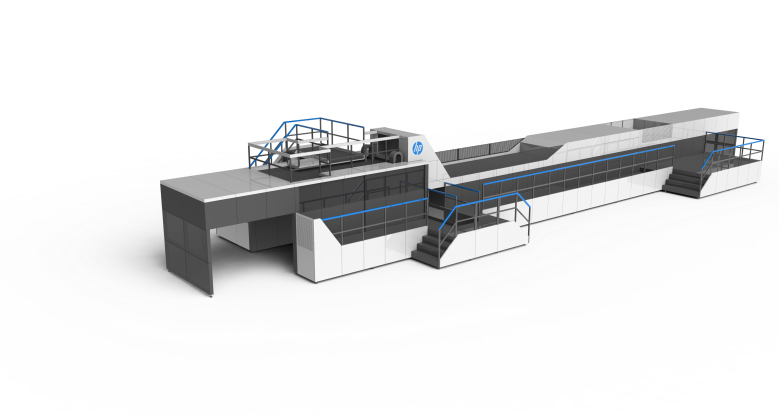

The first HP PageWide C500 Press for direct digital corrugated printing has been installed, at Israel-based Carmel Frenkel.

The digital corrugated direct-to-board printing press is not yet ready for commercialisation, the Frenkel press is a beta test site. HP was one of several developers at drupa that showed their intent to move into digital corrugated printing, others included, EFI, Durst, Screen and KBA.

Carmel Frenkel will serve as the customer testing site for the HP PageWide C500 Press, which HP says is now moving a step closer toward commercialisation.

The converter supplies packaging solutions for leading brands, including in the food and beverage industry.

Eric Wiesner, general manager, HP PageWide Industrial Division, HP says, “The installation marks a significant milestone in the launch of the HP PageWide C500 Press. It can address the broadest range of digitally post-printed corrugated packaging applications, including the growing segment of food packaging. Announced at drupa 2016, the first HP PageWide C500 commercial units are due to be installed in 2018 at launch customers in Europe and the United States.”

HP says its PageWide C500 provides a cost-effective digital alternative for offset lamination and flexo production.

“The press delivers offset quality direct-to-board with mainstream productivity on both coated and uncoated papers, delivering packaging with vibrant graphics that preserves even the finest details” says the company.

With its water-based ink formulation, HP says the PageWide C500 will enable converters to print food applications that can help comply with global food safety regulations and industry guidelines.

Wiesner says, “Unlike some other digital printing alternatives, HP PageWide water-based Inks are 100 per cent free of UV-reactive chemistries. Thus, these inks enable robust and trusted food-safe printing for both primary and secondary corrugated packaging.

The HP PageWide C500 press joins HP’s portfolio of solutions for corrugated applications, providing converters with new opportunities to satisfy dynamic market requirements, including speed to market, high customisation and short runs, and supply chain efficiency.

The HP PageWide C500 press prints on 1.3m x 2.5m sized boards as a maximum, with a speed of 75 linear m/min, uses HP Virtual Belt technology for accurate corrugated board handling, which the company says delivers offset quality directly on the board, and supports industrial grade corrugated boards, from the lightest micro-flute to the heaviest double-wall board through the HP Corrugated Grip Technology.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter