Photo Electronic Services (PES) has supplied the Australian market with Durst printing solutions for 20 years. Recently though, Durst has become a significant player in the local market.

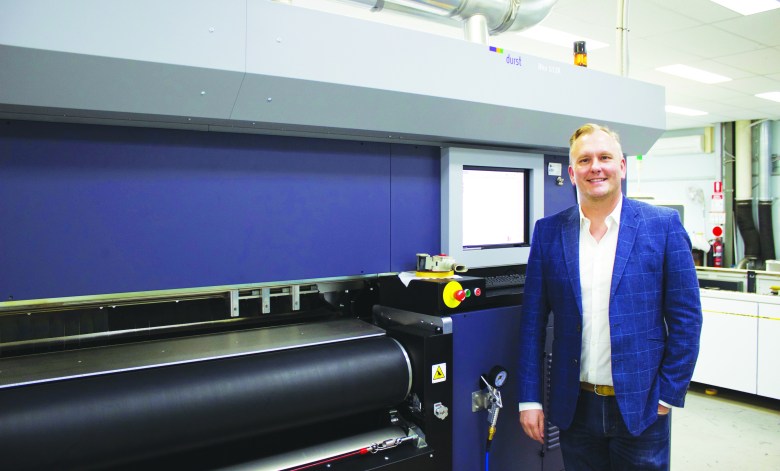

Matt Ashman, sales manager for Durst ANZ, says that change in status has come from the quality and speed of its equipment, backed up by Durst expertise and PES support.

So far this year, PES has sold 10 large Durst devices in the region. He says, “These are not small devices but big ones. We have seen major investment, to the tune of around $6.5m in our large format machinery, which indicates that the level of understanding about what Durst can offer has grown significantly. That speaks volumes about the state of the market here.

Christoph Gamper, Durst Group CEO, also feels the time has come for the market to meet Durst head on.

He says, “We are so pleased to have so many new partners investing in Durst equipment in Australia. The Australia and New Zealand market is so very important to us on a global scale, that is why it is really great to have a great team with Matt Ashman and Paul Taylor on the ground locally.’

Ashman has worked in the print industry for over 25 years, running business in London and then working for Durst Direct in the United Kingdom and Europe. He made the move to Australia with his family just over a year ago, aiming primarily to build the Durst install base and grow the market share for PES.

He says, “Raising the brand awareness of Durst can only get us so far. Much more important for PES is having installations in place so we can actually demonstrate just how these solutions can help signage and print companies increase their profit margins."

Durst’s latest grand format machine, the five metre Rho 512R, has recently made its way into some of the country’s most innovative wide format print and signage shops.

Ashman says, “This machine, the Rho 512R UV roll to roll printer, will change your production, printing at speeds up to 350sqm/hr and the ability to run not only a five metre super wide roll for billboards and building wraps, but also three rolls of 1.6m wide for posters. The advance multi roll is amazing on this machine, and we guarantee it can run overnight unattended, giving you a free night shift.”

Cactus research pays off

Cactus Imaging installed its first Durst Rho 512R printer just before Christmas.

Keith Ferrel, co-founder and general manager of Cactus Imaging, says the company always researches the market before deciding on new equipment, so it had a thorough grounding in the Rho 512R well before the machine arrived at its Sydney plant.

He says, “We take the technology seriously. We test the printers with different substrates and we make sure they will deliver what they say they will deliver. For this piece of equipment, our search began before the previous Fespa. We spent a considerable amount of time going through the various other equipment that was available as well. We needed to increase our output and initially, we looked for a dye sub printer but could not find one that met our needs.

“We also visited the Durst factory and eventually, we made the decision to purchase the Rho 512R printer based on its versatility. Rather than doing just one thing, it can print on a range of substrates such as vinyl, mesh, self-adhesive vinyl, polyethylene and fabric. We have a lot of clients wanting printing on fabric and this machine prints magnificently on fabrics.”

Well established in wide and grand format printing, Cactus Imaging runs one of the country’s busiest plants. Ferrel says, “We are very busy. We are Australia wide and we print a lot of work for countries such as New Zealand, Singapore, Cambodia, Vietnam, Laos, and Myanmar. We print quality and we can do it on time. For example, if we get artwork this morning we can get billboards to Cambodia and Vietnam but morrow morning. Obviously, the Durst machine plays a major part in helping here.”

Despite running such a busy factory, Cactus Imaging continues to look for more. He says, “Without a doubt we are looking to expand we have just bought a five metre digital cutter. That completes the finishing side with this machine. We have looked to diversify the business and we have done that helped by short lead times for the print work. This helps us to increase our capacity and to attract new clients.”

He credits the machine with quality and speed. He says, “The Durst Rho 512R is fantastic; an incredible machine. Certainly the best machine we have had for some time. It’s a five metre machine but the big thing is, at 350sqmhr you are printing billboards but you slow it down and you re orienting point of sale work. The quality is that good. In fine art mode you can print 1200dpi.”

This is the first time he has worked with PES. He says, “PES has been superb to work with, leaving no stone unturned in helping us.”

He has no doubts the industry will follow his company’s lead in buying the Durst Rho 512R. He says, “Well, we do have a bit of a reputation for making the right decisions on equipment. What we buy and use, others tend to follow.”

Ashman believes the companies that install the Durst Rho 512R will see benefits in areas of their business not necessarily related to production speed. He says, “The versatility, quality, and speed of the Durst printers will help these companies grow their customer base. Plus, the Durst technology offers the kind of reliability that a modern business demands.”

Running non-stop

Mezographic, based in Melbourne, employs around 35 staff and produces a large range of grand format print.

The company also recently took possession of a new Durst Rho 512R printer and has put it to good use.

Frank Mezo, director at the family-owned business, says, “The machine has run non-stop since we got it. We run it pretty much around the clock. It is superb. It really is the Rolls Royce of grand format printers. It is actually doing everything that the sales people said it would do.”

Like Cactus, Mezographic had a set agenda in looking for a large format printer and a list of requisites. Mezo says, “Reliability is number one. It is a robust printer; a really solid piece of kit. The media handling system is far better than anything else that is out there.

“We knew what we wanted and we are pleased with what it has delivered. The quality of the product is outstanding. We mainly do point of sale material and it handles it really well.”

This is Mezographic’s first machine from PES. He says, “PES has been very good with any queries we have had. They haven’t had much to do with service and support because the machine is running so well.”

With over 25 years’ experience in the industry, Mezo had often thought about buying Durst machine but had thought them out of his price range. However, he considers the Durst Rho 512R as an ideal solution for the work the company completes and will soon reach the point where the company cannot afford not to have the Durst

He says, “We are extremely happy with it; it has exceeded our expectations. I would have no hesitation in buying another one.”

Bravo for Durst

Bravo Print, based in Melbourne’s Keysborough suburb, has installed a Durst Rhotex 325, the first Rhotex 325 for the southern hemisphere.

Durst launched this machine only four months ago. It can print onto fabric with water-based environmentally friendly ink.

Denny Sebek, managing director at Bravo Print & Design, also researched the market thoroughly before making the Durst commitment. He says, “It is the best printer available. It delivers the highest quality print I have seen; it gives real speed; and it offers us that hybrid functionality.

“We have spent the past couple of years looking for a new printer. There is certainly a lot of equipment out there. What we have seen is that the market has now moved into a new level of equipment and the Durst suits well and truly above the rest.

He visited the Durst factory twice. He says, “We completed some serious testing for this equipment. When you are making a major investment like this you need to know its capabilities and understand the total cost of ownership. I admit I had some concerns but they abated when I saw the quality of the product and the processes Durst uses. The company motto and what it stands for fits well with what we want to achieve. We are setting ourselves up for the next five to 10 years and we chose Durst.”

The company employs 20 staff, mainly on soft signage, retail, and exhibition work. The speed of the Durst will guarantee Bravo can fulfil its production obligations. He says, “We won’t need to turn work away with this machine. Also, I can’t fault PES. The people there have been amazing and they did a fantastic installation.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter