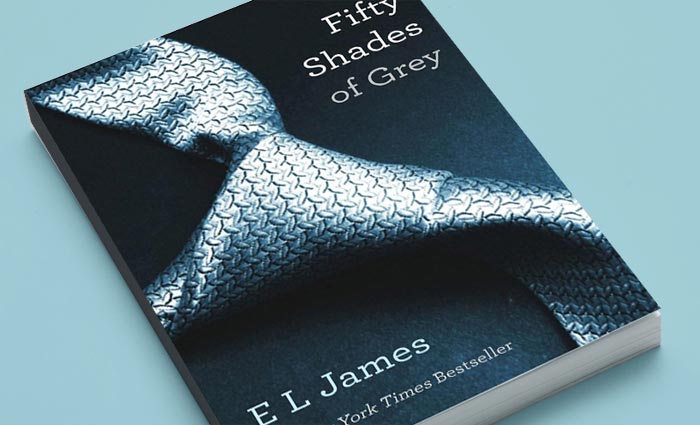

Griffin Press general manager Ben Jolly told ProPrint that the three books in the Fifty Shades of Grey series had been selling so fast that demand had exceeded anything seen for The Da Vinci Code, the Harry Potter books and the Twilight series.

The company has been delivering thousands of copies per day to keep up with demand, he added. The series is published by Random House.

“The average run we print here at Griffin is around 6,000 copies, and the average bestseller in Australia would usually sell around 12,000 to 15,000 copies per week. This book completely demolishes those averages,” he said.

Jolly said the company was used to printing on-demand, but that 50 Shades of Grey had been “taking everything to the extreme”.

“Additional print runs do not usually create logistical challenges as Griffin Press is well geared to deal with this,” he said.

“However, the sheer size and volume of the print runs we have seen over the past two months has created challenges well beyond the norm.

“These include having the… [Norske Skog] paper mill at Tasmania running special runs of paper for us, calling in additional print companies to help with the production of the covers, and calling on our own staff to keep the presses running as many hours as possible.”

Most of the embellishing has gone to long-term partner Protectaprint, while work has also gone to Allkotes and Foilmasters, said Jolly.

Protectaprint managing director Richard Wilkinson told ProPrint that demand had been so extraordinary that he had “lost track” of how many copies had passed through the factory.

Orders started at 250,000 copies at a time, rose to 400,000, climbed again to 600,000 and peaked at 700,000, he said. “We received an order this week for another 400,000.”

“At the very early stages, when people realised this thing was going to go ballistic in sales, the publishers were scrambling to get copies and it put a lot of pressure on everyone,” he said.

“We’ve been running seven days per week, two shifts on it. There’s never a time in our factory when it’s not on a machine or two machines.

“I’ve had people ringing me up, asking me if I can get them copies. I can’t even get copies.”

Wilkinson said the trickle-down effect had been so pronounced that the Adelaide company’s silver foil order had increased sixfold.

“It’s not only good for us, it’s good for our suppliers. The spin-offs for this job are for a lot of people. It’s been good for the industry.”

Griffin has been printing on Timson presses and Muller Martini bind lines, while Protectaprint has been using a Paperplast water-based laminator, Sakurai screen printer and Yawa hot stamping machine.

Click here to read about the ups and downs of PMP.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter