Now that the speeds of the major inkjet press contenders are competitive with offset and LED UV curing has sorted previously tricky drying issues, the advantages of digital smarts such as variable data printing, cloud connectivity, automated job management and integration with analogue workflows are making it potentially unbeatable across various formats.

And while the larger format (B1/B2) space is still the domain of litho presses operating on the efficiencies of fast makeready and attractive cost per impression, partly owing to freedom from click charges – and some will argue there is a marginal qualitative edge – the parameters in which offset is the better choice are becoming increasingly finite with each season of new inkjet releases.

There is much attention on the new crop of inkjet webs, but inkjet sheetfed, and for that matter toner-driven processes, are also thriving in the marketplace. And in the wide-format and grand format sector, a new crop of flatbeds and roll-to-roll presses are becoming the lifeblood of the lucrative signage industry.

ProPrint asked vendors to explain how their offerings can help a print provider’s bottom line in these turbulent times.

Canon Production Printing

Canon is well positioned this year with new technology announcements both in webfed and sheetfed inkjet technology, pushing the technology boundaries further than ever by increasing productivity and further improving the cost model and break-even point against offset with its new ProStream 1800 webfed and varioPRINT iX-series sheetfed inkjet presses, says Herbert Kieleithner, national manager, digital web press technology.

The ProStream 1800 complements Canon’s ProStream 1000 technology, and can deliver over 11,300 B2 sheets per hour. It also offers great media flexibility for coated and uncoated stock and an extended stock weight range from 40 to 300 gsm, he says.

Outlining the business case for Canon’s web and sheetfed technologies, Kieleithner says, “In today’s market everyone is looking how to work smarter, reduce costs and improve margins.

Additionally, offset presses are aging and costs for upkeep and maintenance are rising.”

With high-resolution print heads and developments in environmentally friendly polymer inks that deliver new print quality and a colour gamut “beyond offset”, he sees the ProStream 1800 and varioPRINT iX3200 as “revolutionising the commercial printing business experience”.

Durst Oceania

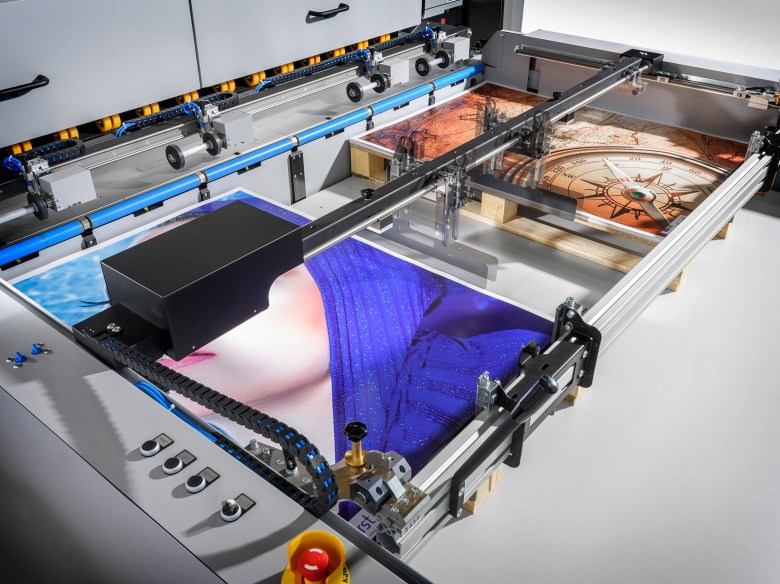

Matt Ashman, managing director of Durst Oceania, says Durst’s range of P5 true hybrid flatbeds offer flexibility and value for money. He describes the features that make the P5 range an unbeatable proposition. “The ability to load multiple sheets and have them all printed together with no alignment needed, being able to print roll media unattended on the same unit, printing boards up to a massive 3.5m width with no length restrictions,” he said.

Meanwhile, Durst’s TAU range of direct-to-media (DTM) inkjet label presses offers options to the label converter, as well as the commercial or wide format printer looking for new opportunities, says Ashman.

“With the ability to print up to 52cm wide at 100 linear minutes per minute, it is the most productive inkjet press in its class,” he said.

“The biggest advantage flatbed DTM offers is flexibility and zero setup cost, no need for expensive screens, no need to store them for your customer just in case of a reorder. No need to have a minimum quantity to justify the cost of the setup of a screen press. You can print one or 1,000 for the same setup cost.”

Ashman’s advice to print providers looking for new opportunities with wide-format inkjet is to “be efficient for those customers who need it fast and be creative for those who need a difference”.

And he adds, “With a Durst press you have both opportunities”.

EFI

Rodd Harrison, EFI’s vice president of sales APAC, says the VUTEk D series is an attractive wide-format offering, consisting of two mid-range roll-to-roll printers that help sign and display customers drive more volume with high-end digital print. The 3.5 metre-wide VUTEk D3r prints up to 204 square metres per hour, while the 5.2 metre-wide VUTEk D5r prints up to 244 square metres per hour. Both are available with options that drive value for users, he notes.

These include colour and white ink with simultaneous clear coating; inline x-cutters and y-slitters; automatic backlit and blockout printing; and media spreaders and motorised winders. As with all EFI UV LED printers, these new releases also provide energy cost savings compared with latex or conventional UV devices, and they enable the use of thinner, heat-sensitive substrates, says Harrison.

EFI’s advanced UV LED offerings emphasise the versatility digital print offers, expanding the range of media users can print on while delivering productivity and cost efficiencies, Harrison explains.

“These printers leverage many of the advanced capabilities from EFI’s highly successful VUTEk 3r+ and 5r+ printers, offering a mid-range solution for an even wider variety of high value applications thanks to its combination of white and clear inks,” he said.

“The printers are equipped with additional printheads which offers both white and jettable clear ink for matte and glossy effects. This enables printing clear flood-coat in gloss or matte and even spot-clear embellishments covering a wider range of unique applications, including wall decorations and murals, window graphics, flooring, high-value prints with selective gloss effects, fleet graphics, and truck-side curtains.”

Fuji Xerox Australia

Fuji Xerox Australia is also well positioned to offer customers outstanding image quality, productivity and flexibility with its broad range of inkjet, toner and flatbed digital presses. It recently launched an upgrade to its popular Versant range with the 3100i and 180i models now available.

When it comes to toner sheetfed, Fuji Xerox also offers the Iridesse Production Press which delivers top quality images at up to 120 pages per minute. The press uses CMYK + 2 specialty colour stations offering the flexibility to overlay and underlay colours at output with a broad selection of specialty dry inks including silver, gold, clear, white, and pink dry ink.

It also boasts the Jet Press 750S, which is the third generation of the Jet Press marque. This four-colour inkjet cut-sheet press delivers 3,600 B2 sheets per hour with what it calls unsurpassable print quality due to its use of SAMBA head technology, pioneered by Fujifilm.

Fuji Xerox’s new Vybrant UF10 is a true flatbed press that produces high quality printing on a range of rigid and flexible media, whilst incorporating LED curing to minimise energy use. It is also supported by four vacuum zones and can print volumes typically up to 7,500 square metres per year.

The company says this flatbed is ideal for businesses looking to grow their capability but with a cost-effective price point.

Kodak

The Prosper Ultra 520 press closes the gap with litho, thanks to superior inkjet productivity, quality and cost, says Robert Mollee, Kodak sales director, ANZ.

“It prints highest image quality two-to-three times faster than our competition, which reduces costs, enables faster lead times and improves customer satisfaction. The press achieves a 95 per cent larger gamut than SWOP (Specifications for Web Offset Publications), which increases sales and customer satisfaction by more accurate colour-matching for the most demanding jobs.

“And the use of lowest cost, water-based Kodak CMYK inks creates more profit per job and allows printers to transition more work from higher-cost offset presses or toner devices.”

Meanwhile, the Nexfinity digital press “is an extremely reliable workhorse which offers unprecedented flexibility with substrate types, formats and thicknesses, along with production using special inks in the fifth imaging unit. It delivers running costs competitive with medium-run offset and prints up to 400 per cent more pages per month than competing sheetfed digital presses. This enables printers to gain a wider range of digital jobs, increase their sales, shift more short-to-medium-run jobs from offset to digital and achieve a faster ROI,” Mollee says.

He sees the Prosper Ultra 520 as the optimal choice for high-quality commercial applications such as direct mail, inserts, brochures, catalogues and books – even those with high ink coverage. And for Nexfinity, typical applications are marketing collaterals, direct mail, short-run publishing, photobooks, calendars, catalogues, manuals, POS materials and packaging.

Konica Minolta

Earlier this year, Konica Minolta launched its new flagship models, the AccurioPress C14000 and C12000. Over four years in development, these toner-based technologies were customised for high-volume colour environments, offering fast output speeds of up to 140ppm on A4 size sheets with a maximum monthly volume of 2.5 million pages.

Grant Thomas, product marketing manager, production print, at Konica Minolta Australia, describes the AccurioPrint and AccurioPress range as “quite diverse – they include everything from black and white, through to colour and even high chroma”.

“In an increasingly competitive market, extended capability with inline finishing options is proving invaluable in helping printers win new customers and retain existing clients. It also means they can turn more jobs around, faster and more cost-effectively which ultimately will help improve the bottom line,” he says.

Meanwhile, the AccurioJet KM-1e is Konica Minolta’s latest digital B2+ UV inkjet press, combining the substrate capability and the stability characteristic of offset presses with the benefits of the latest in digital technology, says Tatjana Ferguson, product marketing manager, Industrial Print and Wide Format, at Konica Minolta Australia. “The AccurioJet KM-1e incorporates even more advanced inkjet print head design with patented Dot Freeze Technology paired with unheard of versatility in offset substrate handling.”

Ricoh Australia

Henryk Kraszewski, senior product and marketing manager, production print, at Ricoh Australia, says the vendor’s extensive portfolio of mono and colour cutsheet presses and high-speed continuous-feed inkjet presses all utilise innovative Ricoh technology.

“A common thread across all of these presses is the breadth of substrates supported. Both the cutsheet and continuous-feed family of presses can run the most diverse array of stocks in their class in paper types, weights and sizes,” he said.

The Pro VC70000 utilises Ricoh’s industrial printhead technology, extended gamut ink technology, patented advanced dryer technology and controller technology to ensure consistent, high-quality output on a wide range of media, including offset coated stocks (with no priming or post-treatment required). Combined with the highest speed in its class, Kraszewski sees it providing a cost-effective solution to the high-volume production of near offset quality graphic communications.

Ricoh offers one mono cutsheet press family (the Pro 8300S series) and three colour cutsheet platforms (the Pro C5300S series, Pro C7200X series and the Pro C9200 series). All colour models are either completely new or refreshed this year.

He predicts that “post-COVID-19, print runs will continue to shrink. That provides significant opportunities for digital presses with their ability to deliver high-quality output on almost any substrate – but with the ability to do so economically on runs from one to thousands.”

Screen GP Australia

Screen has been in the digital inkjet press business since 2006 with the Truepress Jet range, notes managing director Peter Scott. This range has evolved into two distinct categories – high-speed inkjet and labels and packaging inkjet. All are webfed for speed and economy. In high-speed commercial there are two families – the Truepress Jet HD (high-definition) and Truepress Jet NX. The HD series can come with SC inks for offset quality on offset stocks. The NX series is faster and more suited to transactional, direct marketing and mono book production.

For labels and packaging, Screen has the Truepress Jet L350UV series and it recently announced the Truepress Pac830F for flexible packaging on up to 830mm web width.

Screening technology and the Equios workflow are Screen’s own and the machines have proven to be extremely reliable and durable, even in the most punishing environments.

“This, and the fact we do not impose ‘click’ charges makes Screen Truepress Jet presses a more profitable investment in the long run,” says Scott.

“Screen has always believed that the printer should be in control of their costs, and not the supplier.

“Our business proposition is quite simple – we make and sell what we believe to be the best digital presses, we do not charge per ‘click,’ we are competitive on ink costs, printheads and parts, and we service and support our machines for longer than anyone else.”

Scott sees a growing list of applications for Screen’s digital range, including books, magazines, direct mail, transactional, coupons and lottery tickets, labels, shrink sleeves, stand-up pouches, folding cartons, corrugated, sacks and bags and flexible packaging of all kinds.

“Better profitability is to be found in packaging applications, thanks to the value-add of various converting methods.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter