A few weeks ago I was sitting with friends in a popular café on Melbourne’s bayside, and I started a game. I challenged the other diners at our table to see how many different kinds of print signage they could identify. First they looked puzzled, because to the industry outsider, as we know, printed signage just blends into the infrastructure. It is there, but hardly an item to think about consciously or to comment on.

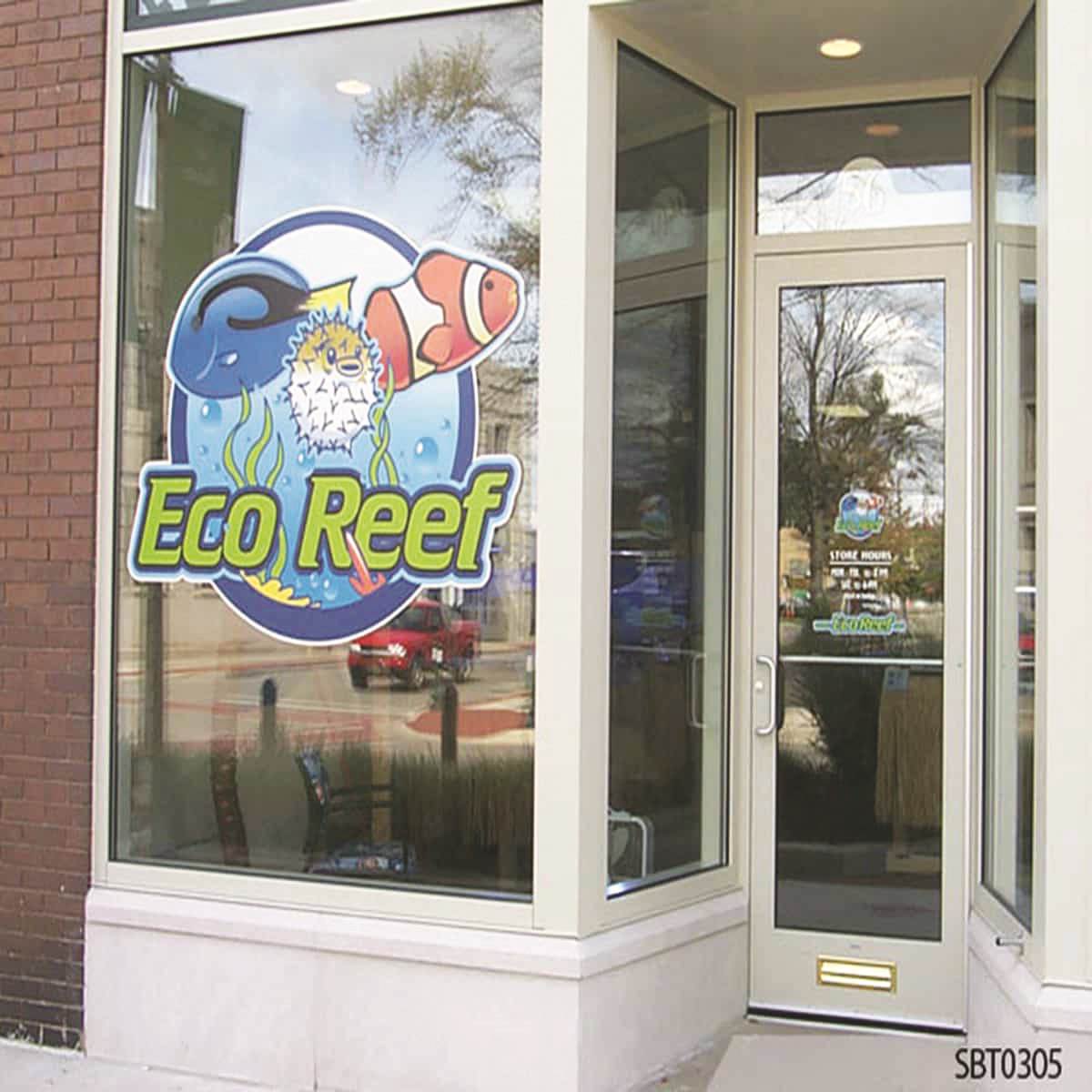

But as we began our quest, we started to identify printed murals, large wall-mounted posters, and some impressive entry signage. Add to that some counter displays and life-sized menus, and you had print everywhere as a silent witness to our afternoon sojourn.

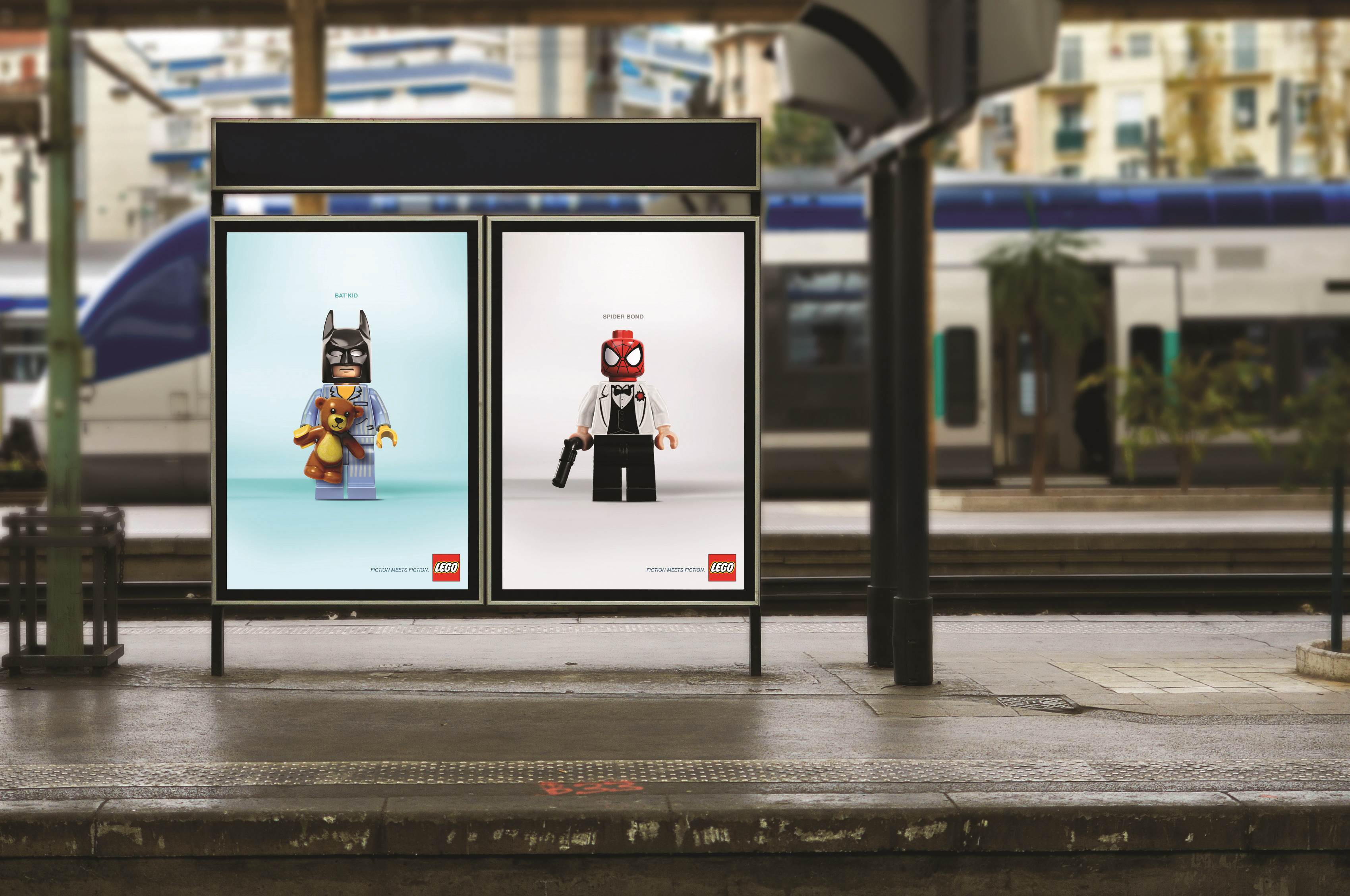

Everywhere we look today, we are surrounded by a forest of signage – on billboards, bus shelters, benches, hoardings, at the shopping centre – and on the surface, there seems to be a lucrative market for supersized printing in Australia.

But next time you are at your local shopping mall, check out how much of the signage is electronic. LCD displays are durable, can be instantly switched to new content, and can display a rotation of content.

The onus has been on print technology to match that nimbleness. High volumes of offset printed signage simply is not cutting it anymore in the race with electronic signage, but some of the top manufacturers of printing hardware are coming up with solutions that harness the flexibility of digital printing to the mega-formats used in DOOH and retail POS applications.

As anyone who attended the Fespa show in Berlin a few months ago will attest, digital wide-format printing is taking centre stage – and that trend will no doubt be reflected at Visual Impact in Sydney in September.

What the vendors say

From the perspective of seasoned industry observer Garry Muratore, who is product manager, graphic arts, at Océ Australia, opportunities in wide-format printing can be viewed in two ways. “Firstly there are opportunities where existing jobs and applications can be performed better. This can be achieved by taking advantage of newer technologies and applying them to existing production tasks. There’s nothing really new in this approach, as printers have being doing this for decades. It is the whole reason international trade shows such as Fespa exist, allowing printers to shop for technology that will give them an edge.

“The second way is a little more creative and involves creating new and innovative applications that can be produced with existing print processes. It has been often quoted that 90 per cent of digital print applications are yet to be thought of. This means there are huge opportunities staring printers in the face if they are prepared to move beyond the norm.”

At the recent Fespa event Océ displayed a range of technologies that Muratore sees as a potential catalyst for increased opportunities in wide format. “In terms of increasing efficiency, we held a technology demonstration that integrated robotic handling in our flagship Arizona 6170 XTS printer. Full-size boards were loaded and unloaded to an automated Océ ProCut finishing system using robotic media handling. The latest version of its Océ ProCut workflow software allows for such integration.”

Muratore says speed and automation are also a consideration in the roll-to-roll printer segment. He says the Océ Colorado 1640 has already established this segment, “Having a printer with such speed means that finishing needs to be up to speed as well. Océ has always offered offline solutions such as the ProCut S3 and G3 range, however at Fespa we demonstrated an online solution with technology partner Fotoba that enabled finished print to be processed in an automated and linear fashion without operator intervention.”

Océ also used Fespa to announce Océ Touchstone, a technology solution that allows customers of Océ Arizona 1200 or 2200 series printers to produce textured and/or optically interesting prints using elevated (3D) print techniques. The solution is delivered to two distinct user personas – the designer and the printer.

“For designers we offer Océ extensions for Adobe CC Photoshop and Illustrator. This allows them to take advantage of the offered facilities without any need for extensive training,” says Muratore.

“On the print production side, the printer receives a PDF from the designer which contains both colour information for the final top layer of the image, as well as information about the topography of the final image.

“The print provider can easily create the multi-layered print job required to realise the designer’s intent. The steps are the same as for printing a normal 2D job, making access to the high value print results easy to acquire for any printer with an appropriate Arizona printer.

“Once printing begins, the printer carriage height is automatically adjusted after each layer is printed to ensure the optimum print gap – and therefore highest-quality output is achieved. This allows many layers to be printed unattended, and potentially extends the working day for the printer without incurring higher attendant labour costs.”

In wide-format printing, UV ink technologies offer the best ways to exploit new applications and technologies, says Muratore. With superior adhesion qualities, printing on substrates such as glass, acrylics, metal and wood becomes easy and achievable. “Proving the point were last year’s Océ Arizona Print Awards, with two of the three major prizes awarded to applications utilising glass as the media. In roll-to-roll printing, Océ UVgel has allowed media such as thin foils and papers to be used. Typically these types of media prove problematic in older latex or eco-solvent technologies, because of the potential to deform due to heat from the drying process.”

Asked about the impact of electronic signage, Muratore sees it as ‘greatly exaggerated’. While digital signage is finding a niche, it is an area where an advertising message needs to be changed and updated regularly, but it offers little or no advantage in the majority of print applications, he maintains.

“For example, short-term campaigns, typical of what political parties utilise, make great use of coreflute, banners and stickers. In the area of location signage (parks and public places), they need to be suitable for the environment – outdoors – and may contain elements of braille. Safety signage that requires specific colours and reflective substrates are just a few examples of the applications that are unlikely to give way to digital signage.”

DTG

Epson Australia is urging printers to take a close look at its offerings at the upcoming Visual Impact show in Sydney. “Developments in fabric printing technology are exciting,” says Nathan Fulcher, marketing and communications manager for Epson Australia. “Look out for new DTG and dye-sublimation offerings from the manufacturers, including Epson.”

Fulcher sees short-run and custom printing as the wide-format area that Australian businesses should be investing in. “For example, digital label printing can support nimble versioning capability for greater profitability and dye sublimation or DTG fabric printing can broaden merchandising offerings.”

He sees developments in ink chemistry and head technology promising increasingly exciting applications in the near future. “Due to the fact that it is a contactless technology that does not use heat, the proprietary Epson PrecisionCore head technology is particularly suited to a broad range of ink formulations and ink materials. Fusions of head technology and materials science will see more and more digital print applications for industry – and Epson will be a key player in these developments as well.”

Fulcher is upbeat about print’s ongoing slice of the display pie, even in this era of encroachment by electronic display technologies. He says, “I think that some of the print being ‘booted’ for digital signage currently will actually come back. Make no mistake, digital signage is here to stay and rightly so; it is fantastically suited to certain applications. However, there is a fad element to some digital signage simply because it is shiny and new. Given the advantages that print has in terms of cost, flexibility and simplicity, there will be opportunities for skilled printers to claw back some of the losses to digital.”

But to take advantage of the short-run and customisation opportunities available, print providers have to add or expand digital capability, he says, pointing out that short-run commercial desktop label printers or dye-sublimation printers are great examples of the digital equipment that modern businesses need to invest in.

In the signage and décor sector, Epson Australia is offering its S-Series eco-solvent printers for superior output and cost effective operation, says Fulcher. For fabric and merchandise printing, he recommends Epson’s F-Series dye-sublimation and DTG for flexible output capabilities and low maintenance. For posters and graphics, there are the P-Series production aqueous printers for high colour range with fast print speeds and a low running cost. And for desktop and industrial labels, ColorWorks is ideal for high-mix label requirements and SurePress delivers even more versatile printing and consistent quality, he says.

New opportunities

Jacob Higgins, marketing and event coordinator at Roland DG Australia, identifies a range of new opportunities available to wide-format print businesses using UV printing technology. “Whether you already supply customers with branded giveaways and personalised accessories, or you would like to expand your product offering to meet increasing customer demands, UV printing is the perfect solution. It gives you the ability to transform ordinary low-cost objects into personalised, high-profit items.”

Higgins finds UV technology is becoming more affordable and accessible. “It presents an opportunity for sign shops and print service providers to quickly realise a return on investment and achieve significant profits. A UV flatbed printer is quick and easy to set up, and variable data allows for customised output on multiple objects. The technology is economical for one-off and short runs, prototypes and custom and personalised products.”

For personalised items and promotional products, UV printing can create one-off graphics products. By combining CMYK with white and gloss UV inks, a real visual impact with embossed effects can be achieved in printing graphics with detail and colour on a virtually unlimited range of items, such as giftware, accessories, awards, and even larger items like skateboards, clocks and tables, he explains.

“The commercial world is evolving and modern clients are constantly looking for new and interesting ways to promote their brands – UV printing allows you to supply this demand. No longer perceived as a novelty, there is massive growth potential with promotional products that can include phone covers, tablet covers, thumb drives, pens, key rings and golf balls. The range of promotional products and substrates that you can customise is virtually limitless with UV printing technology. It prompts the question ‘what can’t you print on?’ rather than ‘what can you print on?’ ” says Higgins.

For interior printing and décor, UV printing technology enables printing directly onto a variety of materials such as leather, wood, ceramic, stone and acrylic, for decorating or personalising a broad array of plain surfaces such as cushions, furniture and upholstery, divider screens, glass splash backs and wall hangings. Even smaller items such as picture frames, vases, lamps and door handles can be made unique with UV printing technology, he notes.

Higgins sees Roland DG’s UV printers as the ideal technology to capitalise on the increasing demand for personalisation and bespoke print services. “Our range of LEF Series UV printers allow you to print directly onto a vast array of objects and materials, including 3D items up to 100mm thick, enabling users to take on a wide variety of work across various sectors. Roland DG will continue to explore markets where these capabilities can be applied, allowing businesses to generate new high-value opportunities.”

Trends

Industry specialist Ashley Playford sees new wide-format opportunities in the realm of trade printing. The national sales manager, graphic systems, at Fujifilm, who emphasises he is expressing his own opinions on wide-format trends, which do not necessarily reflect the views of Fujifilm, believes what is happening now in wide format mirrors developments in A3 offset some 20 years ago.

“There were so many individual A3 offset printers producing short-run work, then digital and trade printing came along. With trade printing you can produce many short runs ganged together on a larger high-speed press. The net result is a higher-quality job at a cheaper price than you can produce inhouse. I see this as an area that has not been fully exploited yet in the wide-format market,” he says.

What does Playford see as the new applications and opportunities in wide-format printing? “There are definitely more and more opportunities in the niche markets such as glass and plastic,” he indicates. “As ink chemistry advances, you will see more and more opportunities in this field, as well as being able to print on a wider range of traditional substrates with one ink system.

“Globally we have a team looking at new and emerging markets where print can be used to improve their processes and increase profitability. For example in the USA, we have an Onset running in the middle of a chipboard wood mill. “This is allowing the client to take a relatively low-value product and print a high-value finish directly onto it. We have another site in Europe using UV printing to make bespoke shoes. There are so many applications we can use UV printing for, it is an exciting time for us all.”

Looking back at this year’s Fespa and ahead to Visual Impact, Playford says, “We are now seeing devices that can produce photographic quality at production speeds. At Fespa, there were also some really nice workflow options, such as Colorgate with its 3D scanning and colour management that can reproduce high-value artworks, as well as Caldera’s complete textile workflow from the storefront all the way through to production management.”

Playford has several ideas about how printers can handle the loss of work caused by electronic signage. “I think digital signage for outdoor applications has been a great success, however for indoor applications, it does not offer the same benefits as printed collateral. We are seeing this with the rise in soft signage. This gives the retail stores a high-end, vibrant print that showcases their brand in its best light.

Playford says, “I can see more and more print in stores in the future. Brands have spoken about in-store theatre, and in an age when you can purchase virtually any item online, people need to be drawn more to the stores and be given a positive customer experience. Print has a major role in providing this experience,” he says.

Playford says Fujifilm’s offerings provide highly effective solutions for wide-format printers seeking to meet these challenges. These include Inca Onset, an industrial UV flatbed; the Acuity Ultra, a superwide-format UV roll-to-roll printer; the Acuity B1, a speciality B1 sheetfed UV press for industrial and niche applications; the Acuity Select 20 & 30 low-end flatbed printer; and the Acuity F.

The wide-format UV market has attracted many top names in the vendor community. Agfa offers its Anapurna H3200i hybrid device with a 3200mm wide image, six-colour-plus-white LED system, which prints onto heat-sensitive boards and roll materials up to 129 sq m per hour. EFI’s Vutek LX3 Pro 3.2m hybrid flatbed/rollfed printer provides high throughput while maintaining image quality, and can be used with a comprehensive range of media. HP’s Latex range, such as the HP Latex 3600, is perceived as the alternative to UV for wide-format signage, decoration and displays. Mimaki’s UCJV300-160 cut-and-print device comprises a 1.6m LED UV printer integrating a cutter, and featuring white ink, which enables four-to-five layer printing. And Neopost’s Aristomat TL high-speed board cutter from Aristo is an ideal companion to a wide-format output device for that extra dimension in display work.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter