Whether you are looking for quality sign and display consumables, beautiful inkjet papers for photography, fine art and graphic art reproduction, textiles and fabrication materials or world class wide format printing, colour management, stitching and cutting, Starleaton can help you.

Peter and Lea Eaton started this wholly Australian owned family business from their Sydney lounge room in 1979 when they imported a few pallets of laminate and sold them off to complement their framing supplies business.

Now, with Starleaton having offices across Australia and New Zealand and the next generation of Eatons in charge, it has become the trans- Tasman home for some of the world’s finest consumable and hardware products.

Zünd, EFI, Epson, Hahnemühle, Neschen, Brett Martin, Roland, X-Rite, Contra Vision, Neenah Coldenhove and Impulsa are among the big names Starleaton has in its range and each of these products were given their very own chance to shine at PrintEx in Sydney in August.

Starleaton’s 350 square metre stand was the largest at PrintEx, which was attended by over 5,000 people across four days in August, with millions spent on equipment and services.

“It’s forever challenging making sure our customers are aware of everything we do,” Starleaton chief executive officer Ben Eaton said from the floor at PrintEx.

“So we needed this amount of real estate to demonstrate all the end-to-end product offerings we have inside each category.

“Textiles is a very good example. We’ve got everything from the colour management, the printer, the media, the finishing including the calendaring unit, then the cutting, then the stitching.

“Nobody has anything like that on offer. They’ve got either stitching, or they’ve got printing but we’ve got the whole package.”

The approach paid off with all major hardware sold off the floor at PrintEx.

So what was in the box?

Significant effort and creativity was poured into Starleaton’s “What’s In The Box” themed stand with marketing manager Ines Eaton the chief force behind it.

The display was certainly eye-catching drawing visitors inside to a world of possibility with different rooms showing the transformative power of printed vinyls and other consumables stocked by Starleaton.

The bright blue “swimming pool” complete with a pool ladder and shimmery textile emulating the water above was a big drawcard.

The room was created using Neschen’s Easy Dot wall material and Print’n’Walk dot vinyl which can hold up for three months of high traffic without laminating after printing.

Neschen international sales manager German Kallmeyer said the Easy Dot Print’n’Walk vinyl has been a game changer in the printed adhesive space due to its easy application.

“Almost ten years ago Neschen developed this dot technology so it’s our own development, we have pioneered this technology,” Kallmeyer said.

“Small air channels are created for easy application using dot technology.

“You can easily install graphics bubble free without tools and it is easy to remove when no longer needed.

“There is a wide range of different Neschen products using our dot technology including the Easy Dot Print’n’Walk which is for floor graphics.

“This film is certified so even after printing you don’t need lamination. Meaning they can quickly apply the graphics all by themselves without installers, this has big advantages for shop owners with both time and budget.”

The Brett Martin range of rigid substrates also featured in the rooms which visitors streamed through gathering new ideas. Brett Martin has been in business for 60 years and started out producing plastic roofing products before moving into PVC Polycarbonate and PETG for print applications 25 years ago.

Director of export sales Michael Colquhoun says the foam PVC Polycarbonate and PETG, distributed solely in Australia by Starleaton, is of the highest quality.

“Our foam PVC is like high-quality paper so if someone wants a high quality job they will put in a high quality foam PVC,” Colquhoun said.

“The advantage of this sheet is it is self-supporting and much stronger than other sheets.

“One exciting product is Fomalux x-tra. It has three layers of sheet with a black recycled sheet in the middle. It was developed to use recycled materials and it has become quite successful because it has many different applications now apart from signage.

“As a product it can stand on its own due to its layered composition, regular foams are not as strong and it is excellent for routing applications.”

Hahnemühle’s fine art papers were also on display creating a visual masterpiece, along with Contra Vision window films and Oppboga waterproof outdoor boards which are fully recyclable and used in the recent federal election campaign.

Founded in 1584 as a paper mill in Germany, Hahnemühle’s range is ideal for artistic premium digital inkjet printing and has a variety of finishes including gloss, matt, smooth or matt textured.

For the environmentally aware, the Oppboga range of outdoor boards is an eco-friendly alternative to plastic.

It is 100 per cent biodegradable and water resistant making it suitable for indoor and outdoor applications.

The board is infused, rather than coated, with water-resistance which means it has no plastic content and can replace foam PVC, foam board and polypropylene flute for outdoor use up to approximately 12 weeks.

Time to step outside?

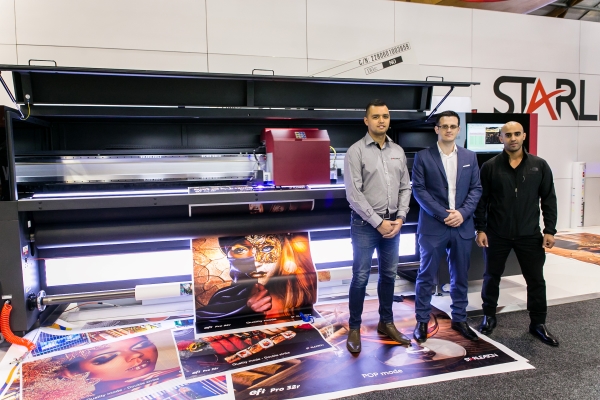

Outside the box was Starleaton’s range of printing hardware – think EFI’s new super-wide Pro 32r and its hybrid 16h device along with Epson solvent, textile, photo and poster printers, and a Roland LEF – all busy printing visual displays.

An X-Rite colour management space was available with visitors able to use their own product samples and test the technology out for themselves. Starleaton is leading the change when it comes to the importance of colour management.

EFI Pro32r unveiled

The EFI Pro32r is the latest in EFI’s super-wide format range and had its first Australian showing on Starleaton’s stand at PrintEx. It’s early days in Australia for this press but it has already had its first installation at Sydney’s Allprint Graphics.

The versatile printer can print up to 207 square metres per hour in four colour CMYK with an optional white ink for greater opportunity and its inks are accredited with 3M MCC warranty. It can also handle double sided block out printing and is easy to use as demonstrated daily at PrintEx.

The EFI 32r has 7 picolitre UltraDrop technology for high definition production and comes with an up to 635 dpi true resolution, uses LED for lower power consumption and can handle thinner substrates.

EFI Vice President of Sales, APAC, Rodd Harrison said the 32r press is the latest generation technology in a continuing evolution of printing platforms from EFI.

“The EFI Pro 32r is a production-level printer that enables customers to be more competitive and profitable as it prints up to 207 square metres per hour, includes a built-in EFI Fiery digital front end with FAST RIP acceleration technology, and has a low production cost due to all the technologies we’ve built-in,” Harrison said.

“The efficiencies of the writing system are a result of the total package, not one single part, and that translates to a superior total cost of ownership (TCO); and a reliable platform that owners can trust to get the work out on time, efficiently, with economical production cost.”

All stitched up with Impulsa

Next is German-made industrial sewing machine Impulsa Synchromatic ATS. Impulsa has been manufacturing sewing solutions for over 70 years.

Impulsa sales director Nigel Reeve demonstrated the machine at PrintEx and showed the ease with which silicone keder could be stiched onto fabric for light box installation.

The keder, comes in either biodegradable silicone or PVC, clips into the inside of the lightbox frame.

The multi-purpose machine uses an industrial sewing machine head with the remaining hardware built by Impulsa. It was first developed for curtain production but has been redesigned specifically for the graphics market for stitching flags and banners to name a few.

The corners are programmed for automatic stitching and the conveyor is 100 per cent synchronised to the speed of the machine enabling it to handle extremely large banners without puckering.

“This machine will guarantee the finished size matches the start size of the unsewn banner as it is completely synchronised,” Reeve said.

“The main benefit is you don’t need to be skilled to work this machine.

“We install them into printing companies and within two days the people that are doing the printing are doing the sewing and this is companies who have never seen sewing machines before.

“A lot of printing companies will send this out to be done and they lose control of it and many companies now want to bring it back in house and that’s where this machine fits.”

Impulsa recently come on board with Starleaton and Reeve said the interest has been strong.

Zünd: The ‘Rolls Royce’ of cutters

Starleaton industrial sales manager Ian Cleary can’t speak highly enough of the modular Swiss-made Zünd cutter G3L 3200.

The cutter comes in a variety of sizes and can handle any substrate, with the exception of glass and solid steel, and can be easily fitted with different blades as required.

“Zünd are known as the Rolls Royce of the industry,” Cleary said.

“They are the best cutter in the world and a machine that businesses aspire to own. They are the fastest, most efficient and most reliable cutting system on the market. Easily running rings around its competitors when it comes to speed and accuracy.”

A key feature is its modular design which allows a customer to start with a smaller investment and add extra features such as a conveyor extension system, overhead cameras or extra tooling as demand grows.

“It is possible to start with a lower investment and build up from there. As the clients’ business grows, tooling can be added, so if the customer is in the packaging market and cutting corrugated cardboard, then needs to be cutting MDF we can add the tool at a later stage.

“They can even access the tools they need through our new rental program.”

Ease of operation is another key feature with Cleary describing the software interface as intuitive and user friendly.

“We do all the installation training and application training as well because it’s not just a cutter, there are so many different applications we can help customers who wish to expand their business. We do all that during the installation process and across the life of the customer’s machine.”

Starleaton Finance

In response to the difficulties faced by printing and graphic arts businesses in obtaining credit, Eaton launched Starleaton Finance in March.

“In these times of uncertainty with the recent banking royal commission people have been nervous in terms of ‘are they going to be able to get access to funding?’,” Eaton said.

“So our whole philosophy with Starleaton Finance is to make that process easier and get them the right type of funding. The printing space in general has been really tarnished by the demise of many of the traditional commercial printers globally.

“When PaperlinX went down in Europe, there was a flow on effect in Australia, so the whole print market has been bundled in with a portion of the market that is having to reinvent itself.”

A complete shop

Starleaton wanted to set up a ‘print factory’ at PrintEx and it did just that.

The creative minds at Starleaton and its sizeable team of trans-Tasman industrial experts plus visiting suppliers from Europe successfully pulled off an immersive display that really did show the vast potential offered through creative print.

Not only did the machines operate non-stop but the walk-through rooms provided visitors with an experience for all the senses.

To learn more about Starleaton visit www.starleaton.com.au or call 1300 880 605.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter