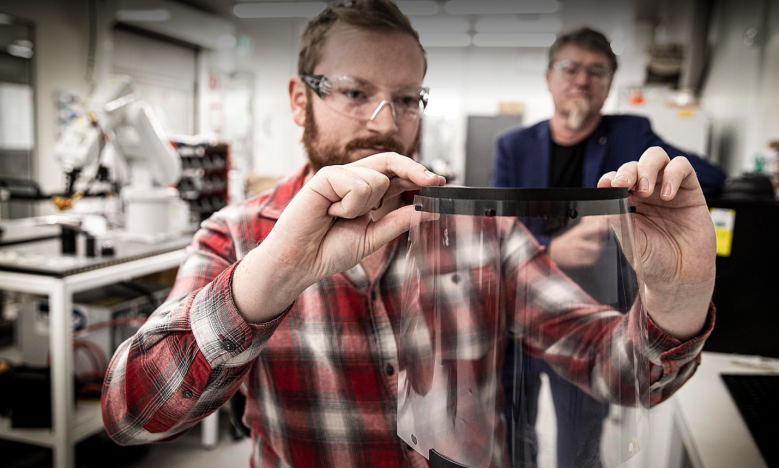

As healthcare providers face a shortage of devices and structures that help in the COVID-19 crisis, University of Wollongong (UOW) research teams are pooling their 3D printing capabilities to produce face shields to protect the region’s healthcare workers.

UOW researchers from the ARC Centre of Excellence for Electromaterials Science (ACES), the Translational Research Initiative for Cellular Engineering and Printing (TRICEP) [supported by the Australian National Fabrication Facility (ANFF) Materials Node and MedTech and Pharma Growth Centre (MTPConnect)] and UOW Makerspace have combined forces to provide local protective gear solutions during the global COVID-19 pandemic.

“It turns out great minds think alike,” ACES/ANFF/TRICEP director Professor Gordon Wallace said.

“Our team at TRICEP, facilitated by ANFF, had been working on a 3D printed face shield design, when we were contacted by UOW Makerspace, who was working on a similar concept.”

The groups are now working closely with the Illawarra Shoalhaven Local Health District to determine what can be produced using local 3D printing capabilities, as well as refining designs and producing prototypes for final testing at Wollongong Hospital.

In parallel, the team will move towards scaling up production in collaboration with local industry to produce hundreds of the shields per week.

The initiative draws on expertise and facilities available within ACES and the ANFF Materials Node, both based at UOW’s Innovation Campus.

Professor Wallace said the 3D printed face shield has demonstrated the true spirit of collaboration in times of crisis.

“We’re working towards a common goal and can move quickly, which is critical as face shields are in high demand, there is a great shortage of them and they are needed immediately,” he said.

“In these unprecedented times, I’m impressed at how quickly people have come together.”

UOW Makerspace manager Jessica Grozdanov said the face shields initiative highlights the importance of direct collaboration between makerspaces, innovative manufacturing facilities and medical institutions to solve community challenges.

“An open source design for a face shield that can be 3D printed has been circulated internationally. We have 3D printers available at the UOW Makerspace which got us thinking whether our local hospitals could benefit from an initiative like this,” Grozdanov said.

“Makerspaces and other innovative manufacturing initiatives are increasingly playing an important role in the response to crises, as we can respond quickly to a particular need and can offer innovative, local solutions in high priority scenarios.”

The researchers involved in the project are part of a larger national forum of universities and hospitals that are utilising their resources to produce research outcomes and initiatives in response to COVID-19.

The team is also testing capabilities on more sophisticated 3D printing designs, including prototyping components for ventilators such as valves and splitters, if the need should arise.

Photo credits: UOW

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter