Fuji Xerox Finisher D6

The post finishing capability of Fuji Xerox’s production solutions has expanded to provide automation and valued added options to industry leading print quality and productivity.

The Finisher D6 is the newest generation of the in-line finishing range offered for the mid series of production devices by Fuji Xerox, compatible with its Colour 1000i Press, Versant 3100 and Versant 180.

It has the ability to apply up to five creases per sheet enables accordion folding (multiple panels), C, gate and Z fold. Creases can be applied to covers and brochures to produce sleek, professionally finished high end applications.

There is a square fold booklet function that when used in conjunction with cover creasing and three edge trim to bleed produces a booklet that is ready for use or sale. The quality of the booklet is further enhanced by operator adjustable spine pressure. The post fuser oversize inserter allows

pre-printed covers, tabs or other material to be used in the finishing process, opening up opportunities to produce a range of hybrid applications.

Fuji Xerox’s inline finishing allows an increased range of requirements to be met with less touch points, production flexibility, labour efficiency and maximum productivity to provide what Fuji Xerox says is the ultimate value add solution to your business.

Horizon StitchLiner Mark III

Supplier Currie Group says the new Horizon StitchLiner Mark III delivers the highest quality booklets with greater efficiency. The StitchLiner MarkIII features expanded booklet size range and increased productivity up to 6,000 booklets per hour. The system can produce a wider range of products, such as A4 landscape booklets and pocket booklets adding expanded application flexibility. It can be configured as a conventional collating system for offset print production and a high-speed sheet feeder for pre-collated digital production.

The StitchLiner Mark III enables users to meet the ever increasing requirements of the market. Features include: fully-automated settings, in addition to booklet format and thickness, all necessary adjustments which includes length and balance are automated; higher quality booklet, professional quality production is achieved with newly designed systems for sheet transport and jogging, scoring and folding, stitch and fold monitoring, and positive jog register at the trimmer; variable thickness production, true end to end automation for variable thickness production.

Variable stitch length and balance adjustment combined with variable thickness transport adjustment through the trimmer; A4 landscape stitching, expanded format size to meet A4 landscape large format calendar production. Higher productivity is achieved on a wider range of formats, including A4 landscape at over 5,000 per hour; and compatibility, the StitchLiner MarkIII can be integrated with the VAC series collator and HOF-400 high-speed sheet feeder.

Insignia Die Cutters by RollEM

Rollem International is launching its sheet-fed, flexo-magnetic rotary die cutter, Insignia, for die cutting, kiss cutting and embellishing specialty products. Insignia allows all types of printers to expand their product offerings to include labels, packaging and value-added promotional or direct mail products that stand out from their competition and speak to consumers.

Rollem says Insignia is revolutionising the die cutting industry due to its versatility, range of applications and materials it can process. Insignia’s quick set-up and easy changeovers make it suitable for digital printers offering customised consumer products, such as folded cartons for cosmetics, gift cards, ID cards, presentation folders. Beverage labels, retail hang tags, electrical component inlays are all suited for this model.

The range of stocks includes plastics, magnetic material, PVC, styrene, tyvec, polypropylenes and paper up to 30pt in thickness. The Insignia Series is now offered in three sizes; Insignia5 20×15”, Insignia6 20×20” and the Insignia7 30×24”. Using flexible dies, Insignia performs die cutting, kiss cutting, cut-scoring, creasing, perforating, embossing and debossing, all in one pass.

Rollem says another benefit of the Insignia is its ability to offer longer runs with its robust, production level design capable of running up to 5,000 sheets per hour. After cutting, the Insignia offers the ability to not only remove cut product from the skeleton/matrix of the sheet, but it provides the ability to both spread multiple streams of output as well as batch into set quantities of the product.

To further automate finishing, Insignia is offered with an in-line folder/gluer unit to deliver finished, glued products. Insignia may be customised with single or dual magnetic cylinders, or bearer/non-bearer cutting stations to suit the customers’ specific needs.

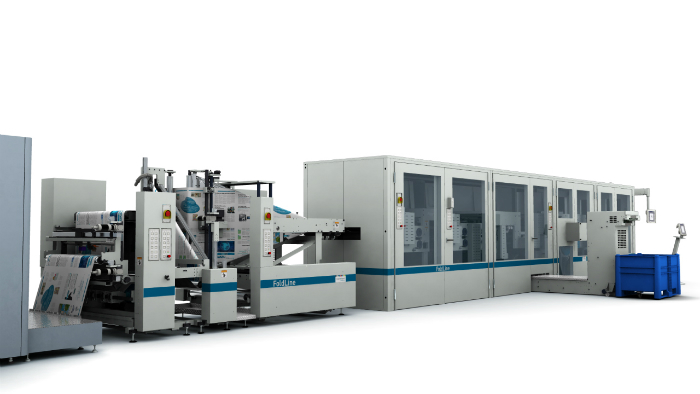

Manroland Foldline

The manroland FoldLine is the flexible digital print finishing solution for newspapers, commercials and direct mailings. The manroland web systems business says it has successfully expanded its applied expertise in the digital print market. Using its own know-how, the company has developed digital print finishing modules, such as the pin folder FoldLine.

The fully-automatic, multivariable pin-type folder FoldLine from manroland web systems is the optimal finishing tool for newspaper production in digital production environments. It provides the possibility to produce broadsheet and tabloid newspapers in long-grain and short-grain format with different structures, and thus ensures maximum utilisation of the advantages of digital printing for newspaper and commercial printing.

The FoldLine can produce up to twelve newspaper sections or up to 96 pages, and so the digitally printed newspaper has the same look and feel as customary offset issues for readers and advertisers. Besides newspapers, the FoldLine can also produce commercials and direct-mailings. In addition, the system can also be used to produce cylinder-stitched booklets and book signatures.

Flexible digital print finishing modules Paired with the finishing components FoldLine and FormerLine from manroland web systems, a modern digital printing system can produce complete book blocks in an end-to-end process. Even auxiliary gluing can be integrated as required. This leads to a substantial reduction in costs involved in conventional book production. Overall systems with flexible solutions such as offline/nearline or complete inline concepts can also be offered and integrated. With short and very short runs, digital printing enables production on demand, which eliminates costs for logistics, warehousing, and overproduction.

Digital printing is thus a flexible and fast method of book production, which manages to unite books and readers more quickly. Digital printing makes good on this promise. Digitally printed books provide all the basic requirements to successfully compete with conventional book production and digital book editions.

MBO K8RS

MBO has matched sheetfed print turnaround times with faster makeready, higher speeds and intelligent monitoring and drying systems with its folding machines.

MBO has a complete range of equipment to handle any speed up to 275 metres/minute in the K8RS model, for an output of up to 18,000 A1 sheets per hour.

The K8 Perfection incorporates numerous MBO features including M1 Control for safe transportation of sheets and easy handling, the VACUKNIFE folding knife for the smallest possible sheet gaps, the patented slitter shaft cassette MWK for short set-up times. The optional Super-KTZ configuration, which enables a wider range of various folding styles, adds more flexibility.

Further extensions to enhance performance include the mobile Z2 knife folding unit for fourfold tasks. Due to the pneumatic drive the cross-fold knife Vacuknife allows a frequency of 40,000 cycles/hour. The open cross and threefold section and the waste paper ejector make the K8 Perfection ideal for standard production as well as for the production of complex products.

Apart from standard products the K8 Perfection is also able to produce complicated products and folding layouts with the integration of numerous MBO specific features for short set-up times.

The MBO range includes delivery systems to suit the output speeds of the folding machines.

Printers can choose from standard belt delivery through presser stackers, and also MBO’s most recent development, the Log Stacker, which automatically collects, stacks, presses and straps book signatures allowing the operator to concentrate on the speed and quality of the output products.

MBO is available in Australia and New Zealand exclusively through Print & Pack Australia.

MGI 3D JetVarnish

Konica Minolta’s MGI 3D Jetvarnish Evo offerings can produce a traditional 2D Spot UV effect, a raised 3D Spot UV effect, and a hot stamp foil all on one unit. They are available in four different widths (364mm, 520mm, 640mm, 750mm) to suit different sheet sizes, and at a length of 1200mm.

MGI says the demand for differ-entiation by commercial printing clients is on the increase. They have a need to achieve greater results from their marketing spend and to separate themselves from their competition. Postpress functions such as Spot UV and foiling effects have been a means to achieve this in the print industry for some time. Now the MGI 3D Jetvarnish Evo brings this postpress offering via a digital workflow. Along with it comes all the advantages of digital printing such as shorter runs, variable data and versioning, no costly dies or make-ready, the ability to make last minute changes and ease of use.

At PacPrint 2017, Konica Minolta announced the official launch of the MGI 3D JETvarnish. It brings with it many new advances that redefines what digital spot UV and foiling can offer its users in postpress workflows to add new revenue streams. For the commercial printer that installs an MGI EVO, they have the opportunity of in field scalability. They can upgrade from EVO 52 (520mm) to an EVO 65 or 75 according to their growth, and how their business changes. This maximises the lifecycle of the equipment as well as increases productivity.

The raised Spot UV and foil effects can be produced at a height of 200micron. This feature alone opens discussions with clients to produce high-class print work. Around the globe, users of the MGI EVO technology are opening new markets for example; braille, short run embossed covers, point of sale material or targeted marketing pieces.

A recent infoTrends study commissioned late 2016 ‘Beyond CMYK: The Use of Special Effects in Digital Printing’, highlights the value of offering postpress special effects. Konica Minolta believes the return on investment speaks for itself.

Muller Martini

With the Vareo perfect binder and the fully size-variable InfiniTrim three-knife trimmer, Muller Martini says it has the perfect team for the production of digitally printed, perfect-bound products in the short and ultra-short run rang.

The innovative drive system on the Vareo Perfect Binder means that the Vareo can be used fully automatically right down to runs of one. The perfect binder can use hotmelt and PUR gluing methods. Muller Martini says it guarantees top product quality thanks to Motion Control Technology as well as barcode matching of content and cover. Its modular design means that it can be used both as a manual machine and as a complete in-line system; and it offers flexibility to grow with customer requirements.

InfiniTrim Three-Knife Trimmer The fully automatic three-knife trimmer can be used as a stand- alone machine or in association with the perfect binder right down to runs of one. The InfiniTrim is size- and thickness-variable from book to book and ensures maximum trim quality thanks to its innovative SmartPress technology. A barcode is used to record

the required size of the end product.

All adjustment elements move into the correct position on the fly. This allows making any sequence of completely format-variable products without stopping the machine and without any operator intervention at all (touchless workflow).

Trimatt

The range of products Trimatt offers adds value to downstream tasks that print companies may once have sent to third parties to finish. Matt Johnson, owner and director at Trimatt says, “We believe printers should keep that work in house, to increase the profitability on their work. That might, for instance, involve personalising, barcoding, gluing and attaching ID cards, membership cards, CDs, sachets, fridge magnets and a whole range of marketing paraphernalia. Or it might mean taking digitally printed media and folding and gluing those pieces to prepare them to go for mailing and distribution. We also offer letter inserting and polywrapping solutions magazines for direct/promotional mail.

Trimatt has machinery to perform the range of print finishing tasks and it can customise solutions. He says, “Because we are an engineering company, we can integrate our systems into existing machinery, or provide stand-alone solutions. It depends on the clients’ specific requirements. In house, we have designed and developed our own inspection machinery for intelligently matching documents. We use camera based technology to read data, barcodes, or numbers.”

Johnson says, “Barcodes and text are all possible methods for specific product recognition. We have deployed our ValidForm Software range into a wide range of machinery, specialising in customised integration for stitchers, binders, folders, wrappers, folder gluers, inserters and so on.

Trimatt continues to develop its solutions for the print finishing and fulfilment sector. Johnson adds, “The Trimatt CardLine series offers users a stand-alone finishing system which gives print finishers, card producers, and other businesses the ability to satisfy a myriad of applications that add real value and, most importantly, profitability to printers. Our locally designed and built Vacuum base is used extensively for feeding and handling flat media and performing finishing tasks like inkjet numbering, promo labelling, card integration and gluing/folding."

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter