Horizon – supplied by Currie Group in Australia – says that at drupa it will present its finishing solutions connected to prepress, a concept aimed to ensure an efficient imposition to improve the equipment efficiency.

It will show the concept of ‘Focus on Post-press, as the key to production efficiency’ through its solutions presentation at the giant show, which is due to open in less than two weeks.

Horizon will host six live presentations on its stand in cooperation with leading vendors from workflow, prepress and press segments of the industry.

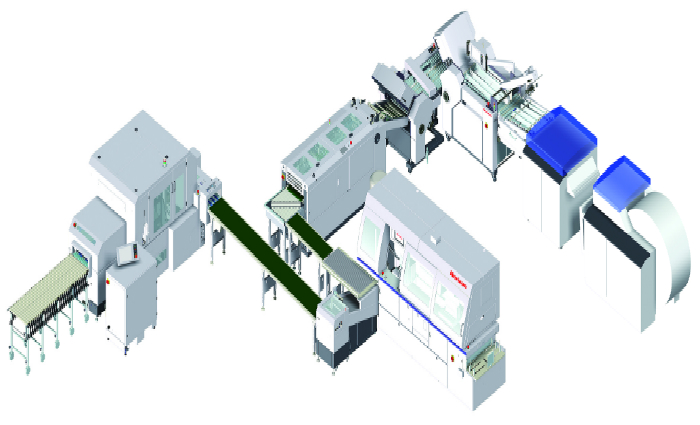

The presentations will feature three Horizon finishing systems including a roll-to-booklet solution; a smart finishing solution of a smaller scale, featuring short run and book-of-one production; and a hybrid smart binding system, which will deliver finished books in one process from continuous-feed and cut-sheet digital print or folded signatures, with variable finish size, paper stock and page count.

At approximately 15 minutes duration, the presentations will focus on finishing from the point of job creation, to ensure efficiency through each step of production, reduce waste, and minimise touch points.

Horizon says that the stand will organise 24 working systems into various zones, featuring perfect bind, stitch, fold, and digital applications. This will include the world premiere of a new perfect binder and folder. The company adds that live presentations will also highlight four innovative smart finishing solutions, each one capable of processing conventional and digitally printed outputs.

The company will launch its BQ-480 variable four clamp binder at drupa. Specially designed to meet the requirements of PUR book binding, the BQ-480 includes a gentle elevator delivery system with a 5mm drop for gentle book handlings. features quick set-up and changeover for variable book production, including for book-of-one.

[Related: drupa 2016 news]

With interchangeable PUR and EVA glue tanks, the binder also offers advanced automation through a movable color touchscreen that allows for adjustments to roller height, nipping height and amount of side glue.

Also launching, the AFV-566T6F fully automated buckle folder features advanced automation. The AFV-566 includes scoring navigation that can be done automatically through the touchscreen panel, automatic double-sheet detection to minimise waste, improved registration and easier sheet loading.

Horizon adds that optional dynamic folding is possible to change fold pattern on the fly for variable signatures with no blank sheets in the set.

Horizon will also launch the Intelligent Feed bookletmaking system. Loading digital printed sheets on the Horizon HOF-400 digital sheet feeder and offset printed sheet in the VAC-600 collator, the intelligent feed system enables combining of the digital printed sheets with offset printed sheets which is picked from selected bins.

The digital printed sheet has a barcode reader at the digital feeder. The barcode information includes the pickup information for the collator bins, which is sent to the collator through the intelligent feed system to mix the digital and offset print sheets.

It then converts the set to a booklet at the SPF-200A bookletmaking system. Horizon says commercial print companies with high volume variable applications will find this system an invaluable asset.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter