Kodak launches the Sonora UV Process Free Plate in Australia, the latest addition to the company’s process-free technology portfolio, previously only available in Japan.

Currently in a beta-phase, the Sonora UV plates will be exhibited at PacPrint, and available from mid-year, according to Robert Mollee, sales and strategic product group director, Graphic Communications Group, Kodak ANZ.

“We see this as a nice fit for UV applications. Process free, but robust enough for high-volume UV printing,” says Mollee.

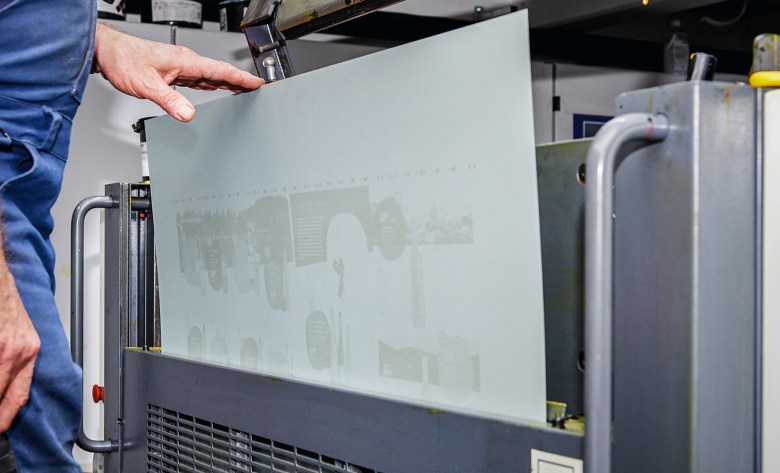

Kodak says the Sonora UV updates the technology from its XJ Process Free Plate, commercially available in Japan since 2016. The process free plates can run on sheetfed, heatset web, and commercial coldset presses and across applications such as commercial print, newspapers, offset packaging, and UV.

The company says the plates deliver longer run lengths for UV print applications than any other process free plate, with up to 30,000 impressions, and that they expand the process free plate portfolio to a wider group of print service providers.

In the pressroom, SONORA Plates work with existing press setups and sequences. This allows printers to take advantage of both the environmental and economic benefits of process free plates and the opportunities associated with UV technology, including flexibility, high print quality, and faster drying times.

Torsten Gröger, production director at cre art Die Werbeproduktion in Fulda, Germany says, “There is no alternative to Kodak’s process free plates when it comes to UV printing. We simply don't have room for a plate processor, and these plates have the general advantage of less effort and lower costs for plate making as well as more stability,”

“The Sonora UV Process Free Plate enables significantly longer run lengths with at least twice as many impressions as we get from the Sonora XP Plate.”

Richard Rindo, general manager Worldwide Offset Print and vice president Print Systems Division, Kodak, says “Kodak is committed to investing in R&D that advances the capabilities of print service providers and equips them to offer a wider range of applications and tackle new markets while accomplishing all that in the most environmentally way possible.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter