Sydney print firm Rawson Graphics is installing an Autobond Mini 76 TH, the latest in a raft of new assets designed to increase its operating efficiency. The move is the latest investment in a busy period for rapidly growing Rawson Graphics; it recently acquired 40-year-old Brookvale operation Artvue Printing, relocating the business to Rawson’s site in North Ryde, and soon after the merged company installed a Komori UV five-colour press, the first of several equipment purchases.

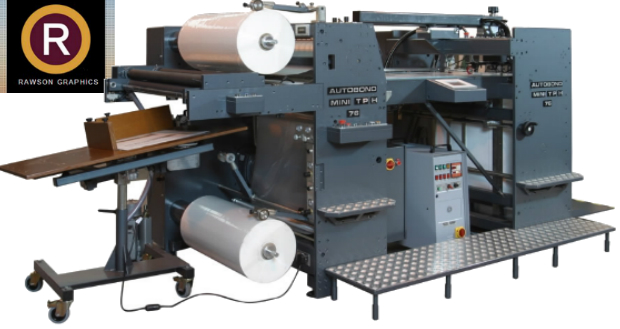

Rawson Graphics has a new addition: an Autobond Mini 76 TH

Lachlan Finch, director with Rawson Graphics, says, “We wanted a robust production model celloglazing machine and we thought the Autobond Mini offered the best ability to deliver that. We evaluated everything on the market, looking at the capacity we needed. “It is crucial for us to achieve the efficiencies that we are aiming for; that we have a full production model that can run efficiently, quickly and cost-effectively. “We do a couple of hundred thousand dollars’ of celloglazing a year on all sorts of different products, it is part of the mainstream service that we offer our clients. We will be using it for a vast range of products from business cards through to presentation folders, covers – you name it.” Equipment supplier Graph-Pak says the Rawson system includes Autobond’s optional Auto Stacker, which returns the laminated sheets back into a pile via air blast, on a machine rated at 60m per minute with fast set ups. Finch says, “Artvue had a small B2 size celloglazer, which we use for shorter run jobs. However longer runs from our B1 press also require celloglazing, so it was necessary after the merger to update and put in a machine that is more capable of managing longer production runs. “Since the merger we have invested in a new guillotine and press, stitching machine, folder and a new CTP unit is coming in next week. After that we have decided that is enough.” These acquisitions, he says, are part of a strategy to improve the efficiency of all parts of the business. Finch says, “I think every printer is trying to achieve efficiency targets, and we need to look at every part of our business, not just capital. “We are investing in the right equipment at the right time to service our needs. This is part of our plan for ongoing improvement in efficiency.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter