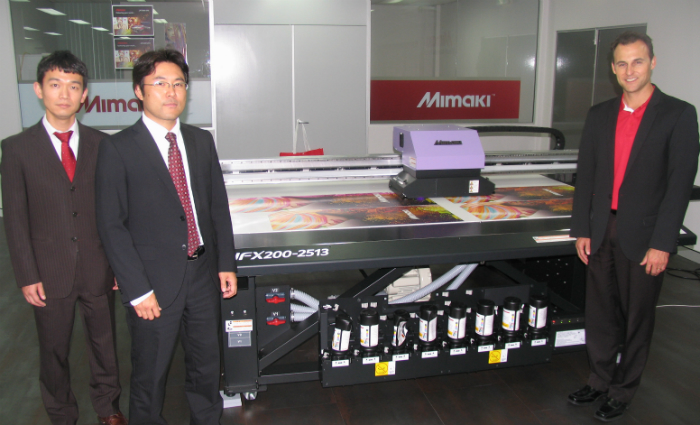

Mimaki has two new wide format printers available in Australia for sign and point of sale printers looking to upgrade to a new model, or get in on the ground floor of UV flatbed.

The two printer are the mid-range eco-solvent roll-to-roll JV300-130/160, upgrade from the JV33 though it will continue to be produced; and the entry-level UV-LED flatbed JFX200-2513, Mimaki’s first entry-level UV flatbed printer.

Mimaki Asia and Oceania marketing manager Ken Seki says the JV300 prints up to twice as fast as the JV33 and includes new features like three heaters and a blower to dry ink faster; an upgraded, easier to use rip system; and can be monitored remotely with text message updates.

It can also be used for heat transfer to fabric for sports clothes and t-shirts.

[Related: More wide format news]

Mimaki Australia national sales and marketing manager Brad Creighton says sign and display graphics businesses will appreciate the functionality and quality of the JV300.

“In addition to the eco-solvent inkjet printing quality that can be achieved with this new family of printers, these printers are also flexible as they can be used for both eco-solvent and water-based sublimation printing,” he says.

“This makes return on investment and the profitable development of new applications faster and easier than ever before for sign and display graphics businesses of all sizes.”

It can print 1.3 or 1.6m with four colour, eight colour or six colour plus white depending on the ink type.

The JFX200 can print up to 25sqm an hour on materials up to 2.5×1.3m and up to 50 mm thick, equating to eight boards an hour with four colour and four with four colours plus white and clear.

It can print colour and clear at the same time and do a glossy or matte finish.

Seki says the main difference between the entry level model and higher spec versions is the size and that it will produce the same 1200dpi quality print as the top end.

“The higher models are for more capacity and bigger print area. This printer is ideal for short run while maintaining quality,” he says.

“It can print on heat-sensitive materials because of LED technology.”

Seki says while latex printers are Mimaki’s biggest growth area, he sees UV overtaking eco-solvent in the near future.

“It is because of the number of media types UV can accommodate and because jobs come out dry and ready for finishing right away,” he says.

He says Mimiaki will get more into UV as the technology develops and bring out many new models.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter