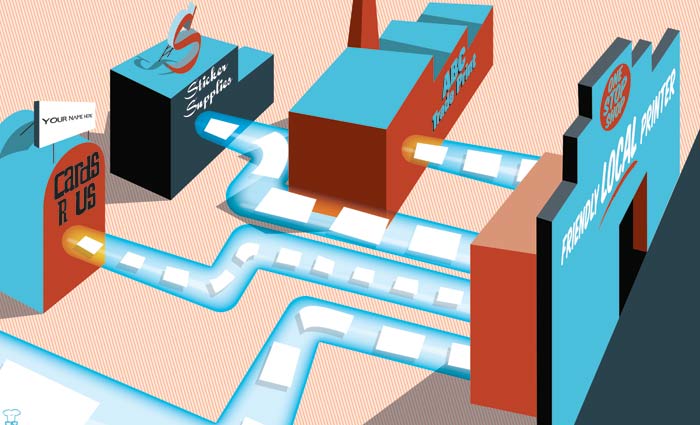

We might be entering the age of the non-printing printer. A number of smaller printers are now discovering that they don’t actually need to produce anything to turn a buck. They can still market themselves as printers and look after their clients, but leave production to third-party suppliers, especially trade printers.

In some cases, it’s driven by economics. In others, by speciality products that clients want but they don’t produce themselves. Rather than lose the client, they farm out the job to the trade printer.

But this comes with risks. There is a loss of control over timing and quality. To manage that, printers need to have a close relationship with the trade printer. This must be a true partnership to ensure it works seamlessly and delivers what the customer wants. The printer must also be careful not to give away precious margin.

Anecdotal evidence suggests some printers outsource up to 60-70% of their sales. A handful outsource everything.

Clive Denholm, founder of CMYKhub, foreshadows a time when more printers will hand over a greater chunk of their work to a manufacturing hubs such as his. It’s a vision of a more efficient future, as opposed to an industry dominated by thousands of costly presses that don’t produce enough to justify the investment.

He would say that though, wouldn’t he? Clearly Denholm’s prediction plays into the strength of CMYKhub’s business model, the company he founded and that is run by different managing directors in different states. But even if Denholm’s theory promotes his hub print model, it still remains a compelling argument.

“Ultimately if you look at printing as a manufacturing process, the current method of manufacturing is inefficient and I think there will be a period of time where there will be some consolidation towards larger, more specialised and well-equipped sites,” Denholm says.

“Whether it’s a few or a hundred, who knows but that’s one layer. For a smaller operator to invest $1 million to $2 million in technology, they are taking a huge technological risk. Whereas we can buy different equipment and share that risk across the equipment. A lot of the operators in the industry are in a position where they don’t want to put their mortgage on the line again for another bit of equipment for an industry that’s very competitive. Our model is to share the technical risk by having hubs which multiple types of equipment being used by resellers in partnership with us.

Still, he concedes it’s not a model that works for everyone. “You have the large, well-set up, good commercial print shops that can hold their own within a market. I reckon they will always be there.”

Nevertheless, Denholm sees more printers now turning to this as a strategy. “From our own viewpoint, if you took the typical medium to small-sized printer, I think they have less equipment and they’re making use of trade printers,” he says.

“It really gives the small operator freedom without putting all their money into capital equipment.”

He says the trade printer’s service offers them real savings. “Obviously they wouldn’t buy it from us if it was more efficient to do it themselves.”

Rod Wood, who runs Perth-based trade printer Large Format Media, says outsourcing is very much the way of the future for the industry.

“As the top end, equipment gets more and more expensive and faster. Printers are now seeing the opportunity where they can do the design in-house and make money out of the design and on-sell to someone else,” he says.

“It’s an economy of scale. Small printers couldn’t afford to spend what we’ve done on equipment so they can’t be competitive against this sort of equipment. But with us as a supplier, they can be. The cost for them to do it themselves is prohibitive, considering the price of the equipment and the hours they need to put in to use that equipment. They find it very difficult to be competitive with machines that are very slow and very expensive per unit.”

Andrew Cester, who runs trade printer Whirlwind, says this is part of a global trend. “Everyone is getting rid of capital equipment and sourcing print from specialists.”

He says some of his customers order specialist print jobs, while others prefer general commercial jobs. “They start out for standard commercial stuff and stuff they don’t want to produce on a digital machine. Then some customers need to go further than that and they might get a specialist printer or their trade printer might do a bit of specialty stuff.”

How do the prices of sending a job out to trade compare to the cost of a printer producing it themselves?

“In some instances we can save people 100% on the cost of producing it themselves,” says Cester.

It would be understandable to assume franchises are an obvious target for this kind of outsourced production model, but Kwik Kopy chief executive David Bell does not see it as a game-changer. For sure, some printers outsource specialist jobs but that’s only because they have to. Many would see a shift to more and more outsourcing as giving away margin, he says. It simply isn’t cost effective.

“There’s some of that happening but I don’t think it’s hugely significant in the overall marketplace,” Bell says. “With our business we’ve always ordered out a proportion of our sales to specialist producers and that portion has certainly increased, but it is still way less than 20% of our sales.

“Well over 80% of what customers order can be produced by our guys in-house; a smaller proportion can’t be, which means you go to the trade-only printers or specialist suppliers.”

Outsourcing only works, he says, if it is a good business proposition. Bell is not convinced this is always the case.

“That percentage may increase a little bit but I can’t see it increasingly significantly for us because the ability to capture profits is all about producing stuff in-house. You give away margin when you have to order out so our guys have always been attentive to make sure they can produce as much as possible in-house.

“But, equally, the balancing act is making sure you can still service your clients’ needs and if they ask you to do something that you can’t do in-house, you have to obviously have to find a way to service their need by getting a specialist supplier.”

100% outsourced

Still, there are print firms that say it’s the only way to go. Saltprint, which produces business cards, fridge magnets, flyers, postcards, Christmas cards, stationery, stickers and invoice books, farms out all of its work to trade printers.

Founder and managing director, James Wickham, says Saltprint started out as a design house and has stuck to that model where it looks after the customers while marketing itself as a printing company.

“We send it off to trade printers but we are obviously a print broker,” Wickham says. “We take the client’s money and take the mark-up out of that but we manage and own the whole process so if something goes wrong we wear that.

“We have never attempted to be a printer. We are kind of like a glorified pre-press house. It’s the logistics from the design to the pre-press to the printing process and despatch until it finally arrives to the customer’s doorstep – we manage that whole process.

“We’re on the front end with the sales, finding the customers and looking after the customers. That way the wholesale press can look after the printing and not have to look after the customers.”

He says it’s about the convenience of providing a seamless service, not the cost. “We don’t have to deal with mixing inks and cleaning equipment and all that rigmarole. I’m sure it’s cheaper to do yourself but there’s obviously a lot more headache as well,” he says.

Micro-printers are the most obvious candidates for outsourcing a majority of work. For whatever reason, they don’t have the scale to justify a broad equipment list, nor the staff to man the machines. ProPrint contacted a range of small firms from across the country to ask how they approached it.

Anita Lennox from three-staff Minuteman Brisbane says her company outsources as much as 60% of production, mainly for goods that her company can’t manufacture in-house.

“We have moved into mailing offerings and you don’t want your customers going anywhere else so we found the appropriate trade suppliers for it,” Lennox says.

The same applies for water bottles, uniforms and signage. She says the arrangement means she can think more carefully about what equipment to buy.

“The only way it would change my purchasing behaviour for equipment is if a trade supplier cannot offer the service and turnaround that I need,” she says.

Lennox says the relationship with the trade supplier is seamless, but it has to be managed to avoid problems. “As a customer to them, I’m very loyal. I know what their print quality is. I meet with them regularly. They do operate as another arm of our business very seamlessly and we don’t have issues.”

Whether it’s cheaper to do the job herself really depends on the volume. “If it’s 30,000 flyers, it’s a lot cheaper to get a trade printer to do it. If it’s 2,000 flyers, we can do it in-house, it’s cheap.”

Arthur Heaps, owner of three-staff Sydney-based Print2day, concurs that it all depends on the order. “As we are all-digital, if I can do it in-house then I would consider that option, but it all depends on the job. Some jobs look and feel better printed offset than digital.

“Anything offset, I send to a preferred supplier. We use a selection of preferred suppliers on a regular basis, some which are recognised as trade-only and some that offer a trade service,” says Heaps.

He says his company has been increasing the amount of work being outsourced “Definitely, each year we are sending more work out and I would expect this to grow over the coming years.”

Heaps, who will not say how much work his company farms out, does identify some downsides. “The downside of outsourcing your print is you are also outsourcing some of your profit. Sometimes prices quoted by trade suppliers for jobs and what you charge your customer do not leave a fair margin for risk or effort. So in some cases doing all the work yourself might be more profitable for some businesses.”

Richard Blundell, who runs two-staff Pumpkin Prints in Hobart, agrees about the downsides. “For a start, you can’t control your quality, and you can’t control the timing for the customer. From that point of view, I would sooner keep it in-house. And the more I can do in house, the more money I can make.”

Pumpkin Prints does outsource some of its sales, but that’s only for services it doesn’t provide itself, such as shopping bags. However, that is only a small proportion of the work coming in.

“Sometimes if I’m very busy and there’s a monster job on, I might think about outsourcing it but when I‘ve looked at it, the price hasn’t been all that wonderful anyway. I find that a lot of the outsourcing stuff is crap anyway so I wouldn’t be bothered. There’s a big push for banners to be outsourced but when I looked into it, the quality wasn’t there so I didn’t bother. I just do it myself.

“Sometimes the outsourcing isn’t that much cheaper and when I put margin on top, it comes out all the same so I might as well do it myself and get all the profit.”

Losing the relationship

Tanya Yachmen, who runs QPrint in Canberra, says managing those downsides is about managing the relationship. It’s not about price, she says, it’s about the ability to work with someone.

“It depends on what relationship you have with these people. If I pay on time and demand certain standards and if I’ve actually gone there and I know the people, it’s a different kettle of fish,” Yachmen says. “If you are just going to get a quote from ABC or XYZ because their prices look good, and then you’re going to be disappointed and your customer will be disappointed you end up with nothing.”

Her company doesn’t outsource much. “We are digital printers, which means we can go to a certain amount of clicks until it is no longer becomes unviable. That’s when we bring in the wholesale printer as an offset printer. But it’s not a huge amount, I’d say it would only be 10-15% max. We’ve got everything in-house.”

Bruno Cristovao from Perth-based Alligator Print & Copy agrees about managing the relationship. “It’s a partnership.”

He says the amount his company outsources depends on the work coming in. “If you get swamped, you can’t handle everything and the client wants it in a timeframe and you are overflowing, then of course you’re going to use a third party.”

The outsourcing question becomes important when considering investing in equipment, which might not be used at full capacity. “You might have a machine that you require to do the service and compete with your competitors but with all that capital investment, you might be using that machine only 30% in the year,” says Cristovao.

Roi McKee from Brisbane-based AFX Digital agrees that the equipment capacity becomes the critical part of the equation.

“We farm out work we can’t do in the building,” McKee says. “It’s as little as possible, just enough to service clients. It might only be 10-20% of the work coming in during the month. But if I’m farming stuff out and making 20% on top, I’m not utilising the equipment I have here.

“That’s fine if you’re turning over quite a bit of work to pay for your machinery but if not, it doesn’t pay for the staff and any leases. If you’re not paying off equipment, that’s a viable option.”

AFX Digital uses trade printers for offset work. Again, managing that relationship is critical. “We have three or four on our books but we mainly use one because we create a relationship with them and they create a relationship with us. Our business is built on service.”

There are risks to this. Plenty of printers have spoken to ProPrint over the years about the potential for trade printers to go direct to the client, cutting the printer out of the relationship. When ProPrint ran a poll in May asking readers, ‘Have you ever had a trade supplier go direct to your clients?’, the results were staggering. Of the 148 votes, some 78% said this had happened to them.

It is the reason why good trade suppliers such as CMYKhub and Cheque-Mates go out of their way to stress their trade-only model. Clients are wary of being cut out.

Can’t beat ’em

Tom Eckersley, managing director Queensland-based Print Approach, echoes widely held views when he tells ProPrint: “Most printers are realising that they cannot match the trade printers that gang jobs and run with minimum options and minimal costs.

“For stock standard items, these guys are hard to beat or match on price. With the advent of online ordering the trade print market is spreading to the general market. Sometimes the same trade printer is trading under a different name and brand to the general public.”

Printers grappling with this conundrum might look to another model. Some companies have developed a system that both outsources and manages to keep things in-house. Excell Printing in rural New South Wales uses a “hub and spoke” strategy that farms out work to different parts of the company. It’s a form of outsourcing, while maintaining the benefits of controlling everything in-house. Some might dub it insourcing.

Excell director Alan Mogridge explains how it works. “We have an offset facility in Pambula and two satellite offices, one in Merimbula and the other in Batemans Bay. We have complementary equipment in each of those satellite offices. In Pambula, we’ve got heavy metal offset presses. We have complementary equipment in each office so we’re not doubling up. We send work around according to the resources.

“It gives us a broader geographic spread. Because we are in the country, we’re not in Sydney or Melbourne where you have a big market to draw from. We are part of a smaller community so we need to have a wider geographic spread and to do that we set up digital facilities in strategic places. We don’t have all the equipment concentrated in one area, we have different equipment in each of those offices so that we can disseminate the work according to where the resources are. We create our own third-party within the same company.”

LinkedIn feedback

ProPrint asked our LinkedIn community whether they see a trend toward printers who don’t print. Jump online and make your point at www.proprint.com/linkedin-non-print

We outsource a lot of our work so one we don’t have to invest in machinery for what is outsourced. It allows us to concentrate on what we do best, almost like a broker I suppose, but we tend to use the same suppliers so have a good relationship with them.

George Feakes, owner, Impressive INKreations

It works well as long as the sales reps maintain a sense of integrity

Jackie Connor, procurement professional, News Limited

That has been tried by Geon and others. There is some benefit to shared infrastructure, but… customers want all sorts of services that are in the main best served by production close to the user. What we can learn is that a printer who has offset equipment doesn’t need to spend millions on a digital set-up and vice versa. Intelligent and thoughtful strategic alliances between like-minded operators can mean a win all round. There are some specialists out there who can help to bring this about.

Kieran May, director, PIAA

We handle a lot of work for printers in NZ and Australia. Through us they are able to compete in the market without having to invest hundreds of thousands of dollars in equipment. Most importantly this enables them to obtain a higher margin per job, which in turn helps their business.

David Reid, managing director, Realmedia

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter