LEP Colour Printers has invested in three new RMGT 9 Series presses from Cyber Australia to improve processes at its facilities in Queensland and Victoria

A company that prides itself on being a fast, reliable, and dependable dedicated trade printing partner, LEP Colour Printers knew it needed some of the best machines in the market to remain competitive, whilst providing fast turnarounds and without compromising on quality.

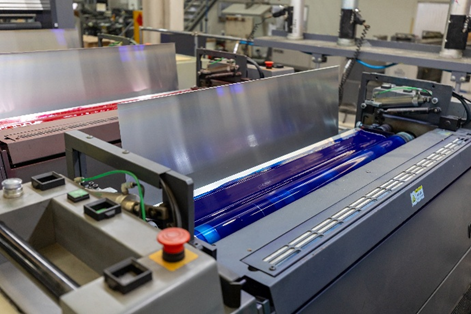

To deliver on these needs, LEP Colour Printers recently turned to its long-time technology partner Cyber Australia to purchase and install not just one but three RMGT 9 Series machines for its premises in Queensland and Victoria, boosting its output, improving its speed to market in multi-folds, and fully transforming its production capabilities.

This strategic investment has marked a significant milestone in LEP’s journey to deliver faster, higher-quality, and more sustainable print solutions to its clients nationwide, highlighting its innovation and commitment to serving the evolving needs of the Australian print market.

Established in 2001, LEP Colour Printers is headquartered in Forest Glen in Southeast Queensland and expanded its operations in 2013 with the addition of a facility in Port Melbourne, Victoria. Its range of products includes business cards, brochures and flyers, DL flyers and cards, stationery, presentation folders, posters, postcards, magazines, calendars, and more.

LEP Colour Printers CEO John Bromfield said, “Our production facility in Port Melbourne was something we invested heavily in. The way our business model works is that with both our production facilities, we’re able to produce jobs in either place, then deliver across the eastern seaboard of Australia either on the same day, the next day, or within a couple of days.

“We specialise in wholesale printing, focusing solely on delivering high-quality results without altering customer artwork. Our lean manufacturing approach ensures timely delivery and cost-effective solutions that help our clients save both time and money. That model has supported our growth and business model, and all through that journey, Cyber Australia has been a business partner.”

Cyber Australia and LEP’s relationship began in 2005 when the former owner of LEP Mike Brooks bought an exhibited Ryobi 755 from Cyber Australia at PacPrint. Through the years, the companies built on this partnership, acquiring the very first RMGT 9 Series press – sight unseen – in Australia when it was first launched and followed it with two more presses shortly after – until now.

With the new purchases, a 920PF-8 LED Smart-FPC and 920ST-4 LED presses have been installed at LEP’s Queensland site, while another 920PF-8 LED Smart-FPC press is making its way into its Port Melbourne facility.

Having had the two machines for about 12 months now, Bromfield said buying the same 920PF-8 LED Smart-FPC press for both of LEP’s sites will allow for colour and quality consistency between factories.

“Because we’re running the same platform on two different sites, from a customer assurance perspective, the result of a job, from a print quality point of view, is going to be the same whether it’s produced in Victoria or in Queensland,” he said.

“Also, back in the day, 75 per cent of our print runs were less than 1,500 sheets and our premises were taking 24 minutes to do a setup or make ready. So, we worked on our Theory of Constraints – which is removing bottlenecks in our business – adopted lean manufacturing and installed these machines to deliver on a ‘Formula 1’ mentality of make ready around five minutes.”

Building on company strengths

According to Bromfield, having been predominantly a short-run, four-colour gang printer, these new presses add to the strengths of the company’s business model of gaining efficiencies on full-colour work.

“Looking at what our business is, what we’re good at, who our customers are, and what we’re trying to achieve, the 8-colour 920PF-8 LED Smart-FPCs and 4-colour 920ST-4 LED presses are the perfect fit for our business needs,” he said.

“Our business is dedicated to supporting small and mid-sized clients rather than large-scale print corporations. We have a clear understanding of our core strengths and remain focused on delivering excellence within those areas. Expanding into fields outside our established expertise is not part of our strategic direction or business philosophy. So, these new investments lend themselves well to the kind of work we do and what our customers require from us – which is speed to market, quick turnaround times, and quality jobs created at an affordable price point.

“With the 8-colour recipe, and with the efficiencies that come from the added features that it offers, we have hit productivity levels that are two and a half to three times more than what’s possible on a conventional press.”

All three sheet-fed offset machines are SRA1 size, which is what LEP has built a business on, with the added benefits of LED UV and convertible perfecting, so that all the jobs get done in one-pass rather than two.

“The perfecting capabilities of these presses is not just about having state-of-the-art technology, but also about speed – printing in one pass with instant curing. For example, we’ve printed magazines on these presses that have been done from start to finish in a couple of hours. The customer was over the moon. In the past, this process would have required several days to complete, as it involved waiting for the ink to dry and managing issues such as markings, scuffing, and bruising. With the latest machines, these challenges have been eliminated, enabling significantly faster turnaround times and an exceptional ability to meet market demand,” Bromfield said.

“The impact on our business has been tremendous, delivering significant gains in both quality and capacity. The presses have effectively given us more time, allowing us to increase production and efficiency. Overall, they have enhanced our operations and established a new benchmark for what it means to remain competitive and relevant in today’s market.”

Advantages of the presses

Handling sheet widths of up to 920mm (900mm printing area), the 920PF-8 LED Smart-FPC and 920ST-4 LED presses enable printing of international A1-size posters as well as 8-up printing in both international A4-size and letter-size. They can also print on paper from 0.04mm in thickness up to 0.6mm, enabling flexible handling of a wide range of jobs, and can print up to 13,000 sheets per hour.

The machines are also highly automated, improving the work efficiency of each printing process. With their Smart- FPC (Smart-Fully automatic Plate Changer) functionality, plate changing is simultaneous. Automatic blanket cleaning and ink roller cleaning also mean fewer manual touchpoints is required.

In addition, with a press information display that enables operations to be monitored at the delivery section and the PDS-E system for managing printing quality, work efficiency is improved by the centralisation of operations at the delivery end.

According to Cyber Australia managing director Bernard Cheong, the LED UV machines also have the added benefit of a 28.5 per cent cost saving on plates and a 43 per cent cost saving on electrical consumption per month when compared against B1-size presses – a plus on the sustainability front.

This is also supported by a newly developed predictive ink density control system that quickly achieves and maintains the target density with minimum wasted sheets.

“In business, there are so many variables. So, if we can remove some of these variables, it is a big plus. In this case, there’s no variable as to how long we need to wait before we can convert the sheet – when it’s out of the press, we can convert straight away, eliminating one of the big variables in printing,” Cheong said.

“These versatile RMGT 9 Series presses offer the latest automation and labour-saving systems, including a large-screen press information display for confirming printing status at a glance, together with the same maintenance functions, sheet-fed air presets, and smart make-ready functions as our flagship RMGT 10 Series.

“Faster job changeovers boost printshop productivity, and the new Smart Assist Printing automatic printing function reduces operator workload significantly, creating new potential for business.”

Futureproofing LEP

With the speed and advantages of LED UV technology now part of LEP’s capabilities, Bromfield noted that the new machines integrate seamlessly with the company’s existing equipment. This alignment is expected to create new opportunities across several of LEP’s key target markets.

“We run a very well organised and lean production operation at both our sites. The new presses sit alongside – physically and systematically – our other machines and this system fits very well with our business in terms of integration,” Bromfield said.

“We’ve already seen additional work coming through various channels since we installed the presses. Some existing customers that used to send their slightly more higher end quality work elsewhere have been sending them to us as soon as they heard about us moving into the LED UV space. The fact that they are already well received by the market is reassuring and encouraging for us. That gives us a lot of confidence in some of the other things we’re looking to do going forward.

“We’ve got a few things in the pipeline, which we want to keep a little closer to our chest until it comes to fruition, but we’re very confident that the machines will be an enabler of these new business opportunities.

“To stand head and shoulders ahead in today’s environment, you’ve got to be contemporary; you’ve got to keep up – not just ahead of the curve in terms of what the market wants.”

He added that the press also suits an environment where it’s very difficult to get skilled trades people – a common challenge faced by many in the printing industry in Australia.

“It’s evident that hiring skilled staff is a challenge for many businesses. The RMGT 9 Series is a future press in the sense that you’re not relying on having a huge workforce. So, you’re automatically reducing your labour costs and your dependency on skilled personnel,” Bromfield said.

“Everybody is working towards what is called ‘dark room manufacturing’, so this series supports the move in that direction. You still need staff, but they don’t need to be as hands-on with the machines as before.

Bromfield and Cheong expect LEP and Cyber Australia’s relationship to only strengthen over time.

“We have a personal interest in the LEP business, so we always look at the best of what we can do and offer. We like to think that we are in this together and the relationship goes well beyond just the sale of a press. We like to work together with our clients to get the best outcome that’s mutually beneficial,” Cheong said.

Bromfield said Cyber Australia has always exceeded LEP’s expectations in delivery, installation, and service, unwavering on its market offerings.

“Cyber Australia has worked with LEP for so many years, and they’ve done installations for us many times,” he said.

“Cyber knows our business very well and we work very closely with their engineers. So, from an implementation perspective, the installs were very smooth, just as always, as Cyber knew what our requirements were from the start.

“Cyber has also been very supportive, working with our business to minimise disruption downtime. As businesses, I believe we work very well together. It’s not just about selling a piece of machinery; there’s an added level of care in ensuring things go as smooth as possible with minimal business disruption. That’s how you strengthen a business relationship.

“We’re very grateful to Cyber and RMGT for their continued investment in this industry and what they enable businesses like us to do. There has been a lot of consolidation in this industry and ongoing challenges for small commercial printers, including significantly rising input costs; the decline in demand for printed materials as electronic mediums continue to penetrate our lives; and the ever increasing shortage of skilled print trades people.

“This partnership between RMGT, Cyber Australia, and LEP shows these printers how our investment in new machinery and producing quality work can give them the confidence to transition from a high cost, high risk printing operation to a low cost, sales focussed business where margins and profitability are higher by outsourcing work to LEP.”

Bromfield added Cyber Australia has also always gone out of its way to support LEP in its endeavours.

“With Cyber, we’ve always had the faith that they’ve got our back. There has always been a depth of specialist mechanical and electrical engineers available to support us in unlikely times. It’s hard to put a value on that loyalty,” he said.

Benefits of LED UV technology

The adoption of LED UV technology will allow LEP to:

• Provide sharper print quality and consistency across all jobs

• Deliver faster turnaround times with “dry-to-dry” efficiency

• Offer more competitive pricing and enhanced value to clients

• Expand into new markets with the ability to print on a wider variety of substrates

• Reduce environmental impact through lower energy usage and eco-friendly processes.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter