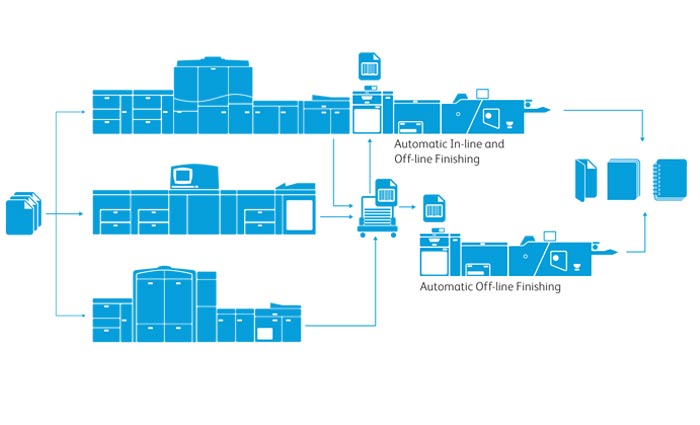

According to Bourg, the new dual-mode BSFEx sheet feeder “enables a finishing production line dedicated to a single digital print engine, also [able] to handle printed output from any number of different presses”.

The sheet feeder is attached to the back of the Xerox iGen 150.

This online-offline flexibility was first announced at Graph Expo 2011 in Chicago. Drupa revealed a step-up in automation with a complete JDF-XML workflow.

The new model comes with a handheld barcode scanner that automatically passes job data to the finishing line.

James Tressler, director of marketing and branch operations, said the deal was exclusive to Xerox, meaning the sheet feeder can only be physically attached to any one of 12 different Xerox digital presses.

However, beyond this exclusive deal, the technology is a model of openness.

This CP Bourg-Xerox innovation – a dual-mode sheet feeder with a bypass transfer – can now be found on competing equipment from the likes of Plockmatic and Rollem, some of which is also being demonstrated at the Xerox stand.

The sheet feeder can also accept a stack printed on any number of non-Xerox presses, both offset and digital, as long as they have a barcode printed.

The finishing line running on the Xerox iGen 150 comprises the dual-mode sheet feeder, a bleed crease module, a booklet maker and square edge.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter