This web-to-print solution means users can set up online stores for both printed and non-printed products. As it is cloud-based, printers do not need to invest in hardware or additional bandwidth. The Online Editor in Apogee StoreFront lets print buyers design or edit their own documents. It integrates with :Apogee Prepress 8, Agfa’s workflow management software. Print orders from web shops can be processed by any of the 8000 :Apogee Prepress systems deployed worldwide. :Apogee Prepress 8 automatically downloads and processes orders from :Apogee StoreFront.

Agfa also demonstrated the newest version of :Apogee 8, which features greater connectivity and supports 64-bit systems and offers optimised imposition for large volume web printing systems. Agfa says that :Apogee Suite 8.0 gives prepress operators more process control. A toolbox of plugins allows them to easily manipulate PDF pages in the workflow.

Arkitex Eversify is Agfa’s SaaS (Software as a Service) solution, which offers newspapers a way to convert their print content for mobile digital publishing, without increasing production costs and still providing a rich reading experience, according to Agfa. Using HTML5 for the reproduction of images, audio, video animation and other content, :Arkitex Eversify enables publishers to deliver their newspapers to a variety of tablet and smart mobile devices. Apogee Impose now supports web offset printing. Designed for the specific needs of web printing operations, this rule-based imposition software takes all specifications into account, including web folding and finishing requirements, to generate the optimal imposition scheme. It supports single, dual and multiple web deliveries. Apogee Preflight offers improved colour management. The new document-based capability verifies that profiles are attached to all objects and automatically updates incorrect profiles.

Agfa has also extended its plate range with its patented ThermoFuse-based prepress system. The company says its :Azura TS system helps commercial printers run more efficiently and to reduce their ecological footprint. The :Azura CX125 COU (Clean-out Unit) reduces gum consumption considerably and extends bath life. It is designed to handle plate volumes up to 40,000sqm per year.

For newspapers, Agfa Graphics has released two new high-speed plate setters for the high-volume newspaper market. The :Advantage N PL HS (Pallet Load, High-Speed) and the :Advantage N TR HS (Trolley Load, High-Speed), both produce up to 350 printing plates per hour. At drupa, the :Advantage N PL HS ran live, imaging Agfa Graphics’ :N94 VCF chemistry-free violet plates. With a completely new design, it can store more than 6,000 plates configured on two pallets of 3,000 plates each plus an additional cassette, in a fully-automatic setting. The :Advantage N TR HS features a trolley to transport plates from safelight environment to the CtP imager. This gives customers who cannot switch to yellow safelight in the room where the CtP device is installed, the flexibility to more easily and efficiently load the plates in a separate yellow safelight.

The :Azura CX125 COU is the company’s new clean-out unit yields a reduction in gum consumption and can accommodate plate widths up to 125cm, and to handle plate volumes up to 40,000sqm. It has a bath life of up to 7000 sqm and small-footprint design for greater productivity.

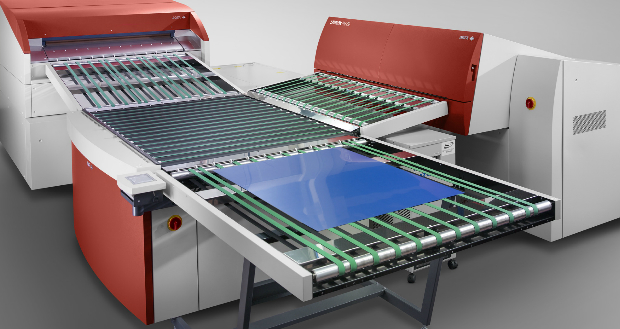

The company also demonstrated its new wide format solutions. The :Jeti 3020 Titan was shown in two versions. First, running ,as a 36 head configuration the machine runs CMYK plus highly opaque white ink, showing pre and post-printing options as well as spot white. In its 48 head version, the system is configured with eight sets of CMYKLcLm ink in both rigid and roll-fed modes. The printer offers a maximum print area of 3.2 x 2m in its flat-bed configuration, and the ability to be modified to handle heavy-duty rolls of material with its FTR (flat-to-roll) option. It prints at the same speeds for roll-to-roll and rigid materials, and its moving table principle assists high precision dot positioning, which enables applications like lenticular printing. It can be configured from a minimum of 16 up to a maximum of 48 heads to suit differing productivity and quality requirements, with optimum print speeds of 226 square m/hour.

Making a first-time appearance at drupa, the M-Press Leopard now handles rigid and flexible materials up to a maximum size of 1.6 x 3.3m and now offers a choice of manual or auto-loading options. It combines technology from Agfa Graphics and Thieme and offers industrial printing on a variety of materials up to 5cm thickness and its bed size has increased to 1.6 x 3.3m and its handles longer media with an increase to 75 vacuum zones for easy positioning of the sheet, while the 29 register pins maintain the correct alignment of the substrate.

With the growth in single-pass piezo-electric ink-jet technology requiring robust specialist UV-curable inks, Agfa is extending its family of Agora and Altamira inks. Agfa’s UV-curable inks are now available for system integrators, OEMs, and industries in a variety of different formulations, researched and developed for specific market sectors and print head integration. Agora and Altamira inks line comprises inks targeted to applications including marking and coding, transpromotional printing, object and decoration printing, label printing, and packaging printing.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter