Canon has unveiled the Colorado XL-series, a new 3.4m printer platform that brings the proven benefits of its UVgel technology to the 3.2m graphics segment, at Printing United 2025.

Available in hybrid and roll-to-roll configurations, the modular, field upgradable platform powered by UVgel technology delivers versatility and productivity for both flexible and rigid media applications.

The Colorado XL-series comprises two models: the Colorado XL7 roll-to-roll printer and Colorado XL7 hybrid printer.

The new series brings the benefits of UVgel to a new market segment with exceptional application versatility across a comprehensive range of media – from banner, paper, vinyl and films to textiles, heat-sensitive materials, foam board, fluted polypropylene, acrylic, aluminium composite boards and cardboard – providing the flexibility to tackle diverse customer requirements.

With print speeds of 70m²/23 boards per hour in quality mode,106m2/35 boards per hour in production mode and up to 211m²/70 boards per hour in express mode, the system delivers the productivity needed for demanding production environments while accommodating substrates up to 52mm thick for rigid applications.

The new platform includes multiple technology innovations, such as the UVgel 860 gel set, which has been optimised to cover a wide variety of both rigid and flexible applications. It also provides the proven benefits of UVgel: odourless and instant-dry prints, high mechanical and chemical robustness, dimensional stability due to low-temperature curing, excellent colour consistency, TPO- and VCL-free, and matte and gloss finish without the need of a separate varnish.

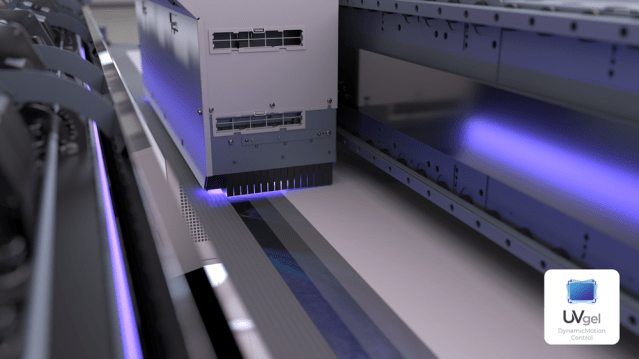

The Colorado XL-series also incorporates new UVgel 850 PrintHeads. Each printhead has 4,544 nozzles and features automated built-in nozzle performance monitoring and compensation. A single printhead supports two colours simultaneously, so that only two printheads are required to print CMYK, plus an optional third if white is needed. Additionally, the Colorado XL-series has an agile and precise printhead carriage that features UVgel DynamicMotion Control to ensure exceptional print quality even with challenging media.

Taking the UV LED curing process to the next level, the Colorado XL-series introduces UVgel FullBeam Curing. This technology uses a unique 3.4-metre-wide LED curing array that, combined with an ingenious mirror system, delivers consistent UV light dosing across the entire print width, guaranteeing exceptional print uniformity over large surfaces and enabling a wider colour gamut.

Media handling is optimised by the new UVgel TRIdrive vacuum belt system, which features three interactive rollers and multiple powerful vacuum zones that reduce wrinkling and skewing by automatically detecting and correcting the media positioning. This results in highly repeatable media transport through the printer, ensuring accurate positioning both longitudinally and laterally and enabling razor-sharp applications.

Optional features for the Colorado XL-series include UVgel White for hassle-free white printing, FLXfinish+ for creative effects using matte or gloss or mixed matte and gloss on the same print without additional varnish, and FLXture for textured finishes that mimic materials like leather, wood or fabric.

Steven Badger, head of sales and professional services at Canon Production Printing Australia said, “Large format print providers in the 3.2m graphics market are looking for systems that deliver high productivity, versatile applications, and reliable quality while addressing the challenge of finding skilled operators. The Colorado XL-series meets all these needs with an advanced platform that combines the significant advantages of our unique UVgel technology with extensive automation and a modular design that can grow with a customer’s business”.

The Colorado XL-series will be available in the Oceania region by mid-2026.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter