What does it do?

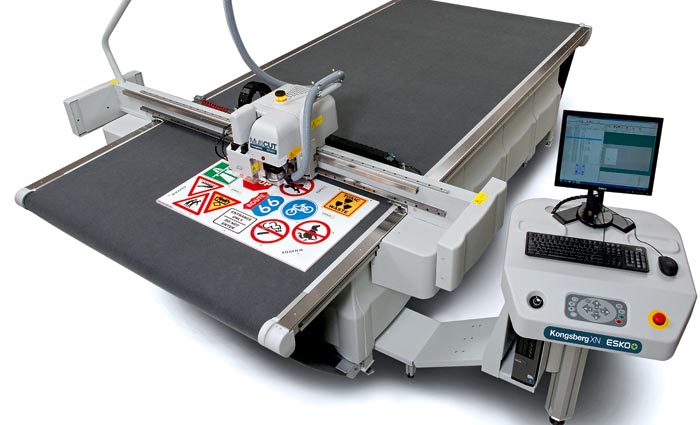

The Esko Kongsberg XN is a new range of digital cutting tables from Esko, designed to cut a wide range of materials, including substrates up to 25mm thick.

When will it be launched and who is it aimed at?

The range was launched at Drupa last month. Available in a wide range of sizes and configurations, it is aimed not only at display and sign printers, but at packaging printers too. Esko Australia general manager Peter Henderson says: “You can have the XN as an entry-level machine for a cutting and creasing operation, or you can have it fully equipped with a camera and a sheet loader more tooling for sign and display and point-of-purchase (POP). It can be configured for the application.”

What are its USPs?

The key development on the XN range, says Henderson, is its new Multicut-HP (high performance) tool head, which can also be retrofitted to Esko’s Kongsberg cutting tables. Enhanced spindle technology allows the Kongsberg XN to handle tougher substrates at a much higher speed than the previous generation of milling technology. Increased cutting performance of more than three times more productive than the XL, says Henderson. “The XL table does the job if you’re cutting materials like aluminium di-bond, foam PVC and acrylic, but customers wanted faster productivity,” says Henderson. “The XN gives higher productivity while maintaining quality.”

The XN also has a larger maximum bed size, reports Henderson, to allow printers greater choice in selecting a table to suit their application.

How does it differ from other Esko cutting models?

Henderson says that although the XN is a new machine, it shares many of its best features with the XL. He also says that Esko’s XP digital cutting table range is better suited to some applications. “The XN range is designed to cover the more common requirement of a table that enables lots of different types of cutting from one day to the next,” says Henderson.

“If you are a general sign and display company doing everything on a whole range of materials, speed isn’t necessarily the most important criteria – versatility is. But if you have a specific performance requirement, like a big POP manufacturer who makes hundreds and hundreds of supermarket POP stands a day, the XP will be the best machine for the job.”

How much does it cost?

The XN range starts at $90,000. “The big attraction for a lot of customers will be that the price is not dissimilar to that of the XL,” says Henderson. “So a general mid-sized sign and display customer will now be able to attempt a wider range of materials for the same price.”

How easy is it to use and what training is on offer?

The XN range employs Esko’s standard iCut Vision system, which makes the cutting table easy to use, says Henderson. The table operation is very easy; customers’ initial training is from one to three days depending on the configuration.

What service and support is on offer?

“All our machines come with a 12-month warranty,” says Henderson, explaining that Esko has dedicated engineers and software specialists to offer remote and on site support. “We do offer support contracts for customers that includes spare parts and a yearly service.

What are sales targets like?

“We expect that the new XN table will be responsible for 70% of sales in the Oceania, as the new table brings increased productivity we believe we will see new customers and opportunities in 2012,” says Henderson.

SPECIFICATIONS

Speed: 50m/min

Max acceleration: XN20, 22 & 24: 5.6m/s2; XN40, 44, 46 & 48: 5.4m/s2

Work area size: From 1,680×1, 270mm (XN20) to 2,210×6, 550mm (XN48)

Max material size: From 1,740×1, 750mm (XN20) to 2,270×6,930mm

Max material width: From 1,680mm (XN20) to 2,210mm (XN40, 44, 46 & 48)

Standard traverse clearance: 50mm

Optional traverse clearance: 95mm

Price: From $90,000 to $250,000, depending on configuration

Contact: Peter Henderson, 0402 102 260, www.esko.com

THE ALTERNATIVE

Zünd G3

The modular G3 digital cutter us designed to be highly flexible and adaptable, says Zünd. The machine cuts materials up to 50mm thick and, says the manufacturer, the selection of sizes, modules, tools, and material-handling options is extensive.

Speed: 84m/min

Work area size: 3,200×3,210mm

Maximum material width: up to 3,490mm

Standard traverse clearance: 60mm

Price: Dependent upon size and configuration, but a typical G3 configuration starts from around £66,000 ($105,000), according to ProPrint’s UK sister title, PrintWeek

Contact: Intergraphic, 0408 866 774, peterw@intergraphic.com.au

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter