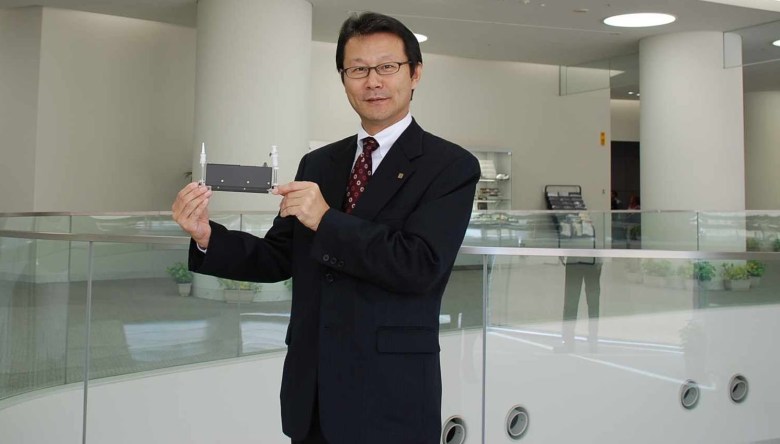

Kyocera, known by its presence in the office market, has introduced its first piezo drop on demand printhead, which could be called the Porsche of printheads. Hisamitsu Sakai (pictured), head manager of the Kyocera Inkjet Division, part of the Corporate Thin Film Components Group, was happy to answer questions on this new development.

ProPrint: While Kyocera is still developing thermal printheads, what triggered the development of a piezo printhead?

Hisamitsu Sakai: Within the three types of digital printing, Kyocera has the world’s fastest technology in both thermal and drum devices. We wanted to also become number one in the last remaining category, which was the springboard for us to get into inkjet printheads.

You developed the piezo printheads jointly with Brother at first. Why did you go the rest of the way alone?

The joint development ended in 2006. Free manufacturing and sales based on each company policies was agreed upon for 2007 onward. We therefore decided to pursue various technological research projects that would allow us more flexibility in manufacturing and sales.

Why did you opt for a wide path (108mm) printhead?

To answer this question I would have to talk not only about width, but also about nozzle density, and speed. We selected a wide path printhead so that our customers can achieve speed and high resolution printing with a lower number of printheads. It is our mission to fully permeate the industrial printing market with inkjet printheads.

In order to make this a reality, the performance of existing inkjet printheads would have to be improved tenfold. Kyocera has made that improvement a reality.

Also, the 4.26-inch printheads can be arranged horizontally for convenient printing of international standard A-size pages with a minimum number of printheads – – one head for A5 size printing, two heads for A4 size printing, and three heads for A3 size printing.

How long do the printheads last?

The drive source for ink dispensing is a piezoelectric actuator. The Kyocera piezoelectric actuator will not stop even after 50 billion discharges per nozzle. The print concentration drops five per cent after 30 billion dots (discharges), which is what we refer to as the durability number.

There are two levels of filters inside this printhead. These two levels of filters function to prevent the common causes of nozzle clogging, including removing impurities from the ink container and filtering out air bubbles.

Following from this, with a filter pass only the ink used for printing is discharged, and even after 30 billion dots (discharges) the inside of the printhead will not clog up.

In order to permeate the industrial printing market, durability is an incredibly significant factor. Kyocera has achieved the required durability with this inkjet printhead.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter