Heidelberg will offer its print customers business consulting to improve their profitability, in exchange for a fraction of the saving they reap from it.

The press giant says the Performance Plus program will identify weaknesses in printers’ operations and implement changes to rectify them.

Harald Weimer, head of Heidelberg Services and former president of its US operations, says the company’s research shows many printers have an overall efficiency of less than 30 per cent and boosting this is key to improving profits.

“It is a completely new approach to our industry. It sets in motion an extensive change process for the customer that is geared to improving overall performance through a comprehensive analysis of the company,” he says.

Heidelberg says US printer Contemporary Graphic Solutions, used as a pilot for the program, boosted performance by 40 per cent and saved US$250,000 and 1000 production hours over 12 months.

[Related: More Heidelberg news]

The manufacturer is promoting the program as a partnership that benefits both it and printers, and ‘the costs of the program are proportionate to the scale of the savings achieved’.

With inability to pay finance repayments on big equipment investments a leading cause of death for print businesses, the move may also help reduce the number of situations where manufacturers like Heidelberg are left grossly out of pocket.

“There are usually a number of weak points where improvement processes need to be applied, but it is sometimes difficult to pinpoint these,” Heidelberg says.

“When endeavouring to improve the overall performance of a company, the interplay between personnel, processes, equipment, and consumables is crucial.”

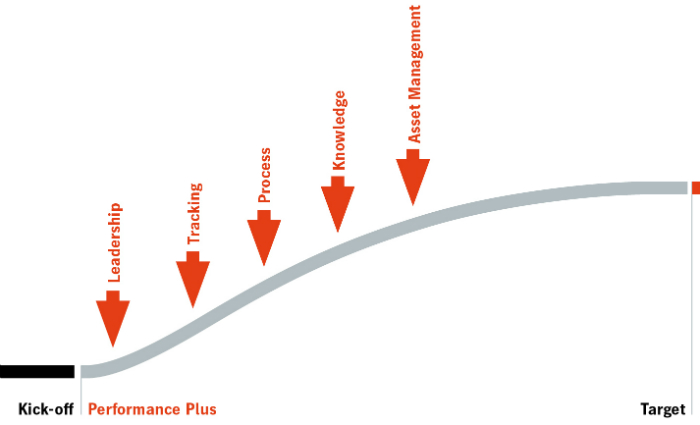

Printers that sign up to the program first have their business analysed to determine its productivity level and weak spots, and how they can be improved.

The consultants will then devise improvement targets and a plan to reach them, incorporating measures like optimised shift models, standardised production processes, staff training, and the use of remote monitoring for increased machine availability.

“Using lean management processes, Heidelberg then helps the customer implement its continuous improvement process to ensure targets are achieved on a lasting basis,” the manufacturer says.

The launch of the consulting service is the latest effort by the world’s biggest press manufacturer to diversify into auxiliary services in the face of declining equipment sales.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter