Tell us about your business

We’re traditionally a commercial offset printer. We invested in digital in 2009 with an HP Indigo 5500. Since then, our business has transformed with web-to-print. We still have a strong presence in the commercial market. We specialise in fine art, catalogues and premium commercial products.

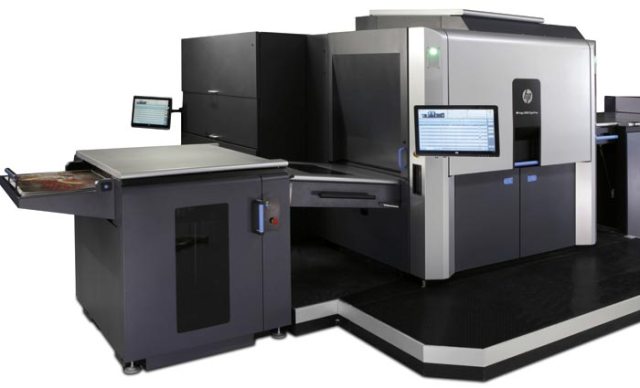

What have you bought?

Our Indigo 10000 arrived on 18 March and produced its first sheet on 21 March.

What does the new press do?

Because the industry has seen a reduction in run lengths, it is there to dominate new markets for us, particular six-page A4 brochures and presentation folders, which in the past have been costly to produce on offset due to expensive makereadies.

Why did you choose this product?

We have a Heidelberg Speedmaster CD 74, which will remain part of our fleet, but long-term we believe digital is the future. The 10000 will be good for variable data and cross-media work – combining it with QR codes, variable imaging and variable text, where we see a lot of demand. Also point-of-sale, product manuals, medium-run catalogues and the fine art market. There’s a market for books with run lengths of 500-1,500, which is where you have the crossover from digital to offset.

Did you consider any other products?

Quality has been the backbone of the Courtney brand for 30 years. When we looked at the first Indigo [in 2009], we wanted something that was the best representation of offset. When we look at the iGens, Nexpresses and Konicas, we felt the toner-based machines didn’t give that offset quality – ink bonding to paper as opposed to ink sitting on paper.

Which features do you like most?

I like the pallet feeder, which enables us to run continuously. The environmental aspect is amazing, especially the recycling unit and how it recycles the imaging oil. That shows a benchmark of where HP has positioned the machine. Also the colour consistency and quality of the image consistently. That’s probably the biggest thing. You print your first sheet, you’ve made ready in three or four sheets, and you get that same consistency through the run of the job.

Is there anything you wish it had that it doesn’t?

No. Once we’re up and running, there might be things that appear, but at the moment it’s everything it’s promised to be, and when we pulled the first sheets, we were very impressed.

How fast is it?

In perfecting, it will run at 1,725 sheets an hour, in the Enhanced Productivity Mode mode it runs at 5,400 an hour and in black-and-white it runs around 6,900.

How reliable is it?

We’ve spoken to a lot of beta sites, and all the news is positive. The machine came in with miles on the clock, which gave us confidence. The amount of support HP and Curries have given us is unbelievable.

How easy is it to use?

It’s easy. They’ve basically remodelled and improved the software from the previous generation of Indigos. Probably the best word to use is ‘unbelievable’.

Will it save time and money?

We’re going to see great efficiencies, in particular makeready times and reduction in waste. Traditionally, offset, you need anywhere from 300-500 makeready sheets, whereas this gives you makeready in three or four.

Will it win you any new business?

There’s already a lot of interest. People see the potential and the capability of the bigger sheet size in the market where there has been nothing like it before.

Were there any difficulties surrounding the install?

Not at all. The guys were fantastic. It arrived on time, the guys got straight into, and we had the machine installed in two-and-a-half days.

How has the service been?

HP and Curries have provided fantastic service. We’ve got a number of HP people from all over the world, a number of Curries guys that are local, and they’ve all been fantastic.

Who is this product right for?

There’s always been a shadow over digital and offset. As an industry, we need to understand that digital is no threat to offset; it complements it.

Would you buy another one?

If all goes well, and it’s very successful for our business, definitely.

Supplier’s response

Currie Group is thrilled to be installing the HP Indigo 10000 at Courtney. Since installing its first HP Indigo press, Courtney has challenged and developed its business model in order to grow its digital business and increase its unique product offering. The additional productivity and versatility of the HP Indigo 10000 will enable Courtney to further develop its business with products and services made possible by the B2 format.

Phillip Rennell, sales & marketing director, Currie Group

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter