Koenig & Bauer recently invited existing and prospective customers from all over the world to an exclusive event under the banner ‘Post-press Solutions Experience’ at Koenig & Bauer in Radebeul.

More than 150 guests from 12 countries were given the opportunity to learn more about the latest solutions for even greater profitability and efficiency at the post-press stages of folding carton production.

The objective of the event was to present innovations in the field of post-press technology and to share comprehensive insights into the future of folding carton production.

It addressed both potential customers and current users who wish to further optimise their production processes and are therefore interested in learning about the latest trends in the industry.

A highly varied agenda allowed the international post-press experts to gather a wealth of information on current and future developments in folding carton production.

Ralf Sammeck, member of the executive board of Koenig & Bauer and CEO of Koenig & Bauer Sheetfed, used his keynote presentation to explain the post-press strategy and digital orientation of the company.

He positioned Koenig & Bauer as a leading partner in the field of folding carton production. Subsequent breakout sessions offered the participants additional, more detailed information on topics such as the service experience, performance management and expanding post-press options.

Practical demonstrations with live production runs and job changeovers presented a broad spectrum of innovative solutions with which Koenig & Bauer is shaping a forward-thinking and efficient future for folding carton production.

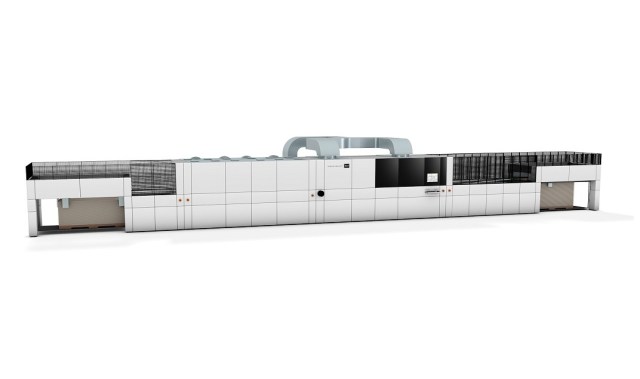

Machines and solutions demonstrations included the CutPRO Q 106 SB, the CutPRO X 106, Ipress 106 PRO SB, Omega Allpro 110, and myKyana.

“At our recent event, we didn’t just talk about our technology; we showcased it live,” Rayne Simpson, sales manager, ANZ – Koenig & Bauer, told Sprinter.

“Customers had the chance to experience our cutting-edge die cutters and folder gluers first-hand. We demonstrated the CutPRO Q106 the SB die-cutter, and the CutPRO X 106 rotary die-cutter, alongside the OMEGA Allpro 110 folder gluer.

“During the demonstrations, we ran real-time production jobs, including make-readies, allowing everyone to see how these machines operate in real-time.

“This hands-on experience gave customers a clear understanding of our capabilities and the quality of our equipment. It was an exciting opportunity to engage with our experts, witness the machines, and see their efficiency in action.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter