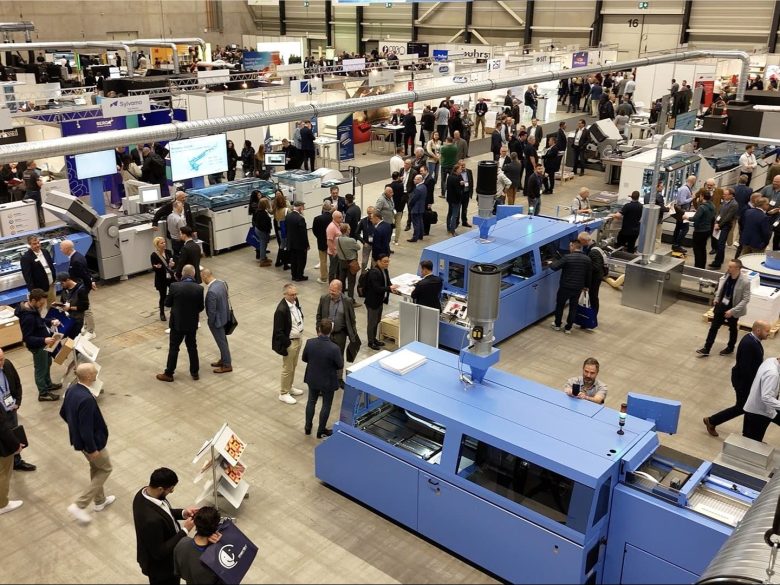

Müller Martini recently demonstrated its industry leading innovation at Hunkeler Innovationdays 2025. The three smart factory solutions presented revolutionise production processes in the digital printing industry for the long-term.

With 6,800 participants and 120 exhibitors presenting 40 live solutions, the event grew once again year on year.

“We are proud that together with our partners, we were able to present pioneering solutions during the four days of the trade fair that will shape the future of the digital printing industry,” Müller Martini CEO, Bruno Müller said.

Impressive smart factory solutions

For the first time, Müller Martini presented a significantly larger booth, integrating technologies from multiple vendors. This setup reflected the broader global industry trend toward collaboration, where printing presses, finishing equipment, and workflow solutions are no longer isolated systems but part of a cohesive production line.

“This is what we face these days. When we talk about ‘Smart Factories’, we talk about combined lines with presses from different vendors, and we add the finishing to it. On top of that, we have our workflow solutions. This approach allows for greater efficiency and flexibility, ensuring that print jobs are seamlessly processed from start to finish,” Müller Martini Australia country manager Ian Sampson said.

All three Smart Factory applications on display captivated countless visitors to the Müller Martini booth and demonstrated how Müller Martini can set new standards for end-to-end production processes in collaboration with its partners.

Visitors also experienced how a finished softcover book was produced inline from both the white roll and the white sheet – from the digital web-fed or sheet-fed printing machine to the cutting robot with subsequent sorting line, fully automated and without manual intervention. Customers from across the globe were particularly impressed, stating, “Müller Martini has networked everything that can be networked on its booth. From the white roll to the finished book – it’s fantastic to see how everything works seamlessly”.

Highlights included the showcase of the Vareo PRO perfect binder and the InfiniTrim cutting robot, which are ideal for digital printing productions, especially due to the elimination of changeover times.

“The ability to implement individual customer requirements quickly and efficiently with these networked solutions is a decisive advantage in today’s fast- moving printing industry. Müller Martini is heading in the right direction with these innovations,” Sampson said.

The Prinova Digital saddle stitcher on show also produced eight different saddle-stitched products in very short runs from the roll in a continuous process.

By integrating finishing solutions such as Hunkeler Unwinding, Folding and Cutting High Precision Binding and Trimming, Müller Martini demonstrated a nearly ‘lights-out’ production environment.

“We needed to be able to demonstrate that such machines can run independently with as little personnel as possible as we know finding skilled operators is challenging,” Sampson said.

“I believe, one of the major challenges in modern print production is handling diverse job specifications on a single roll of paper – there could be 100 different jobs, all variable in content. These jobs may have varying page counts, sizes and cut lengths. Our Connex Workflow ensures every job is tracked and finished correctly, even when dealing with complex, mixed format jobs.”

End-to-end networking

Müller Martini also showcased connectivity at its stand. The Connex workflow system, a key technology to produce individualised print products, controlled all three lines from the digital printing press to the finished sorted product stack. The seamless integration of all production steps, from impositioning the print data to sorting the finished products, fascinated the trade visitors.

Adapting to digital transformation

The printing industry is in a digital revolution, with requirements for shorter print runs and an increasing demand for customisation, according to Sampson.

“To embrace the digital transformation is to remain competitive. Print runs are shrinking globally and the companies that can handle this shift require the right equipment. Müller Martini and Hunkeler demonstrated this at HID25,” Sampson said.

To meet these evolving needs the teams at Müller Martini and Hunkeler have integrated transactional and trans promotional applications expanding their finishing capabilities. With the acquisition of Hunkeler, the Müller Martini portfolio now includes additional applications that further streamline ‘print to finish’ workflows.

As Innovationdays concluded, those that made the effort to travel to Lucerne to witness these efforts were demonstrated to a show of fully integrated, automated print factories that to some was just a vision.

“Seeing was believing. Once visitors and customers see how seamlessly our systems work together, the complexity fades away. With Smart Factories, connected Workflows and Automated finishing solutions, the future of print production is clear – it is faster, more efficient and highly adaptable to market demands,” Sampson added. Müller Martini and Hunkeler, together, continue to innovate and pave the way for a new era of printing excellence.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter