This article first appeared in the September issue of Australian Printer

Having worked with some of the biggest names in the design, fashion, pharmaceutical, industrial, not-for-profit, real estate, cosmetic, finance and banking sectors, the Lighthouse Print Group has always delivered on quality for its end products.

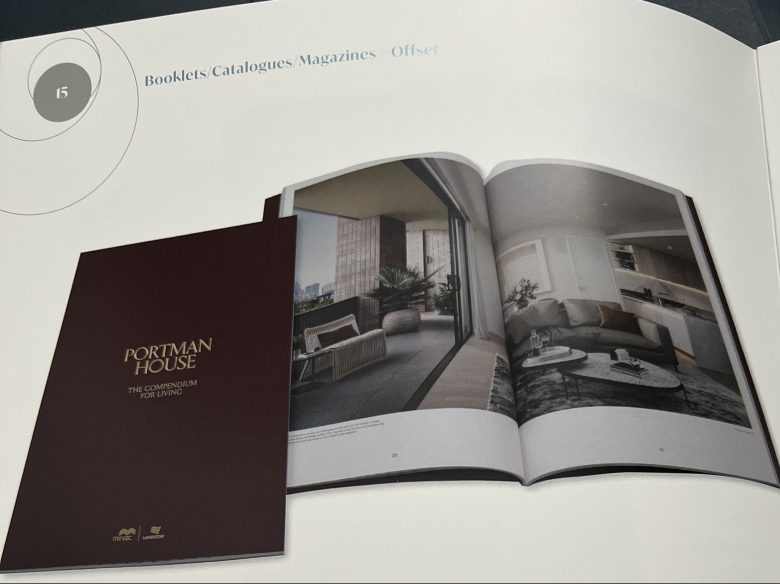

Mirvac is one of the companies that the Lighthouse Print Group has produced various print projects for across many years. So, with the understanding of the quality required, the company was tasked with the role of creating its Portman House book.

The result of this printed product exceeded any expectations and won the gold award in the leaflets, flyers and brochures – offset category at the 2022 National Print Awards.

Lighthouse Print Group sales manager Paul Richardson, who oversaw the project, said, “The Portman House book is a collection of images and explanation of its boutique Portman House building plan, which salutes the ‘30s era style of apartments while incorporating modern designs.

“In line with that, the client wanted a 70-page book-style brochure that reflected the idea of ‘compendium for living’ – incorporating the art deco feel shown in the images of the book and the notion of what sustainable luxury looks like.

“As such, we had to include several quality inclusions and details to achieve this, especially with the depiction of the fine, sculptured brick pattern that was included in the logo and the use of gold printed tracing paper on the first and last page of the brochure.”

Lighthouse Print Group used a Heidelberg XL 75 – 5 + C, a five-colour offset press to print the book. The Heidelberg XL 75 is a machine that delivers high efficiency, productivity, and ease of operation.

With Push to Stop, the efficiency of print production (OEE) can be raised to a high level and the new Intellistart 3 assistance system aids job changes with comprehensive, time-optimised automation.

Push to Stop and the implementation of artificial intelligence offered the Lighthouse Print Group with a unique user experience (UX): autonomous and navigated printing across the entire printing process.

“The run length of the brochure was too excessive for digital production, which was the reason for us to produce it on an offset machine,” Richardson said.

The cover of the book was unprinted with gold foil and hand engraved with an embossing block. As for the text, it used CMYK for white stock, dense black for grey stock, opaque white for claret stock and gold ink for translucent stock. All of the stock used was from Ball & Doggett.

“The Heidelberg has outstanding print capabilities, in particular Impress colour, print registration monitoring and an aqueous coater, which aided the printing and drying process of the gold on the translucent paper and white ink on the claret stock,” Richardson said.

“The remaining text pages were printed on a Knight Smooth 120gsm stock and were also aqueous coated to avoid scuffing.

“Other processes that were used in the production of the brochure included gold foiling of the logo with the use of hand sculptured blocking dies that enhanced the fine detail in the logo and type.”

The book was perfect bound using a Horizon binding line.

However, most print jobs that involve speciality papers, inks and finishes do face a degree of challenges, according to Richardson.

“With white inks, the challenge lies in knowing how much to put down to give the opaqueness without setting it off on the below sheets. The same applies with gold inks on transparent tracing paper,” he mentioned.

“With the printing on uncoated coloured stocks, reproduction and output of printing plates is important to ensure the correct dot percentage is used to allow for images to be kept open and printed as vibrant as possible.

“As Lighthouse Print Group has been in operation for 41 years, two generations of directors and skilled craftsmen by training, we honed our expertise to ensure that we easily avoided these challenges.”

After working on the project for 10 days, the final printed and finished result was very pleasing to not only the Lighthouse Print Group but also the client.

“The team at Lighthouse knew that we had covered all concerns prior to going to press. Importantly, our client was the one that needed to be pleased. Initial production meetings outlining any major print project is a necessity before proceeding,” Richardson said.

And winning a gold award at the National Print Awards for this project was the cherry on top the cake for the company.

“Winning the gold for this job was a reflection on the work that the Lighthouse team applied to the brochure. All details and processes were carried out as planned. In the end, the gold was just the finishing touch that it deserved. The client was equally thrilled,” he added.

“The win is a testament to the quality of work that we provide our clients and that’s how we end up forming long-term relationships with them.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter