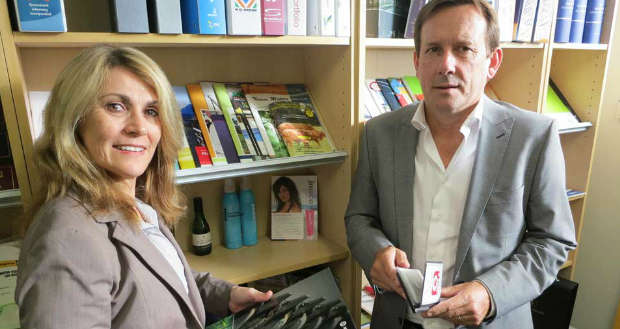

Level three certification: Tennyson Group’s CFO Karen Simpson and managing director Mitchell Simpson

Printers interested in the PIAA’s Sustainable Green Print (SGP) certification will be able to level up before the end of 2014, with training courses set to run around the country. The multi-level programme aims to help printing companies meet their environmental responsibilities, cut costs and gain a competitive edge. Based on an ISO14001 framework, the training provides a choice of three linked achievement levels including up to ISO 14001 for level three. Heaneys Performers in Print, Platypus Graphics, Scott Print, Macquarie University’s Lighthouse Press, Next Printing and Look Print are among 25 Australian printers to reach the highest SGP level. Some 48 printers have achieved level two, and nine printers have completed level one. The PIAA says the programme can help companies save money by helping them to better manage their waste, recycling, energy and water use, as well as energy and air emissions. The programme may also contribute to reducing insurance premiums by helping businesses to better manage the storage and handling of printing chemicals and incident response.

Neil Thurlow, managing director of Accent Press, receives the SGP Certification from Mel Ireland, member services manager Queensland with the PIAA

Companies can attend the PIAA hosted courses in Sydney today and tomorrow July 22-23, and in Melbourne on July 24-25. Other states are currently seeking expressions of interest for local courses. Queensland outfit Accent Press recently completed its level two SGP certification, and says it is seeing bottom-line profits and better efficiencies for making a relatively small number of changes. Neil Thurlow, managing director of Accent, says, “We have gained cost reductions by reducing both our paper and consumables waste which in turn means we are able to offer more cost effective products to our clients and also increase our margins, which makes us a more efficient and profitable business.” He says Accent already had many relevant procedures in place, and it was only a matter of refining them to gain certification. “We were already recycling paper and plates and reducing chemical waste to an absolute minimum. All that we needed to do was introduce systems so we could quantify the amount of materials for recycling and those directed to landfill,” he says. “Some customers are less inclined to print with a company that doesn’t substantiate its environmental awareness claims or have supporting business actions, so we decided to formalise what we were doing and take our business to the next level.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter