Graph-Pak managing director Tom Ralph, who has been building a reputable list of sales distributorships under the company banner since 2006, runs us through some of the products it distributes to the industry, and the discernment involved in its choice of offerings.

Graph-Pak has been supplying blue-chip machinery to the printing, packaging and converting industries in Australia and New Zealand since 2006, and provides specialist service engineers for installations, maintenance, and bespoke projects. Its sister company, Graph-Pak Laminating Supplies, offers a wide range of consumables such as laminators, rubber rollers, as well a range of spare parts, tapes, and chemistry.

The products that Graph-Pak distributes are chosen with care, in keeping with the company’s mission of providing advanced, reliable and functional automated equipment and engineering solutions and services to the industry.

“As the world continues to spin, our markets continue to change, and it is imperative that we change with them. That’s why I choose suppliers who relentlessly invest in R&D to provide the very best automation solutions year after year,” Ralph said.

“My dear now-departed dad used to say ‘no one gets anywhere sitting on their hands except sore hands’. Graph-Pak is exactly the same – I drive the business hard because demands are ever-changing and customers need fast, reliable solutions. They need fast, efficient machinery to meet the ‘on-demand‘ environment, they need prompt courteous service and support when called on, and they need good value consumables that deliver satisfactory results.

“This is the mindset my team and I have. Our customers are our partners, and this is the key to success,” he added. Some of the products that Graph-Pak offers are:

INSIGNIA DIE CUTTERS

Insignia sheet-fed, rotary, flex magnetic die-cutters weigh between 1360 kg to 2495 kg depending on the size of the machine (die cutting section only). Built in the USA using American-sourced components, the machines have 38mm to 64mm thick solid side-frames to house the cylinder section and support the cutting station and can apply up to 1360 kgs of downward force directly to the cutting station.

The cutting dies utilise flexible die technology to work on a rotary magnetic cylinder system. The cutting tools, or dies, that the Insignia machines provide are available in a variety of different hardness depending on the substrate to be cut as well as the lifespan of the die and can perform die cutting and kiss cutting on the same tool.

A flexible die can be produced with radiuses of a circle that are not achievable on a steel rule die, as well as obtain proximity of cutting blades that is not available on flat bed dies. Flexible dies take up little space – they can easily be stored on either a tabletop or in a file cabinet.

AUTOBOND MINI 53 TH LAMINATION MACHINES

Autobond is a third-generation family-owned engineering company in the heart of Derbyshire, north of London, England which manufactures a range of high-quality lamination machines, ink jet spot UV, and foiling machines to enhance and protect print.

Its highly skilled engineers take pride in producing top of the line machinery that is renowned for its quality, reliability, and productivity around the globe. Highly active in R&D, the company continually expands into new technologies and applications including:

• Ink Jet Spot UV/High Build Spot UV/Digital Embellishment/3D Spot UV

• Foiling

• Roller Coat UV

• PSA Magnet Lamination

• Embossing

• Thin Film Laminating Machines

• Thick film Encapsulation/Edge-Seal

• PSA Release Liner Backing, Floor, Window, and Counter Graphics

• Reel to Reel & Reel to Sheet Autobond Mini 53 TH, a best seller for Graph-Pak in 2022 and 2023, is a quick make-ready, one or two-sided, sheet-fed, thin film thermal laminator designed specifically for half-size offset and digital format applications. It has a modular design to add options such as a perfector, automated stacker, in-line UV coating, or an in-line foiling machine.

Some of its other features include:

• Ideal for short and medium run lengths

• Max sheet size: 53cm x 75 cm

• Min sheet size: 32cm x 22.5 cm

• Max speed: 50 m/min

• 115 gsm (80 lb text) to 650 gsm (24 pt)

• Quick make-ready

• Easy operation

• Small footprint

• Heavy-duty build quality

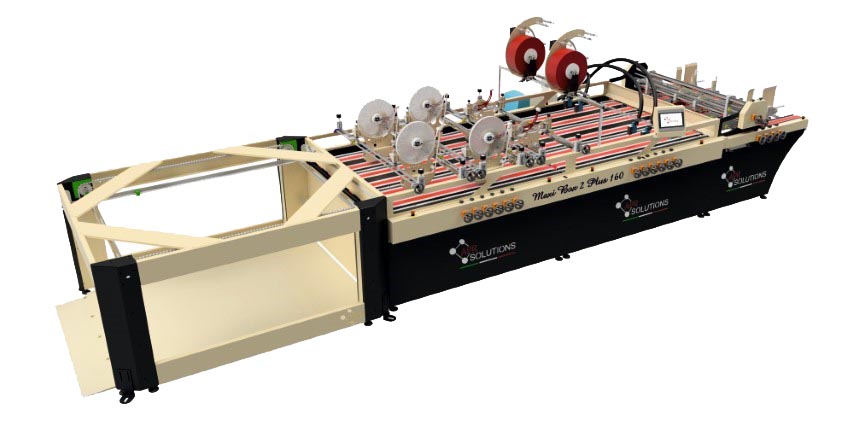

APR SOLUTIONS’ MAXI BOX PLUS MACHINES FOR E-COMMERCE

Maxi Athos Plus machines are designed to apply double sided tape with automatic feeders. Specifically designed for the corrugated market and Forex materials,

the machines are available in two sizes:

160 cm (Maxi Athos Plus 160) and 220 cm

(Maxi Athos Plus 220) and are available in up to six RAP applicators.

Other features of the machine are:

• Supports stiff cardboard, corrugated cardboard, PVC, plastic, acrylic, wood, and aluminium foil

• High-precision applicator placement with the new linear make-ready system

• Pneumatic shafts lead the product towards the delivery unit avoiding materials jams

• A professional operator is not required

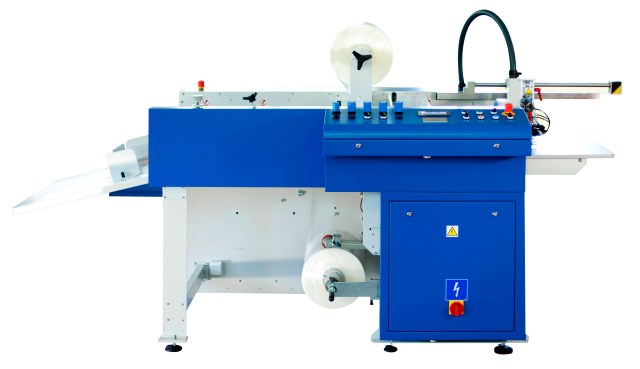

EUROPA – B2 FULLY AUTOMATED LAMINATORS

A fully automatic laminator for sheets up to B2 size, the Europa is compact and easy to use and ideal for the print-on-demand market. Based on the successful Jupiter range, its features make it equally adept at running both digital and lithographic output.

It includes a suction feeder which offers a deep pile for longer-run work and is easily adjustable for a variety of different sheet sizes, as well as an infeed roller. The roller presents lightweight and digital output to the laminating and nip rollers where a missing sheet detector helps to prevent unwanted wraparounds.

Its other features include:

• High pile feeder to maximise efficiency for longer-run work

• Heated steel top roller

• Rubber nip roller

• Scrolled in-feed roller to help feed lightweight and digitally produced sheets

• De-curl bar which can be adjusted on the run

• Burster type sheet separator, automatically separates sheets up to B2 size

• Integral catch tray to suit various sheet sizes

• PLC controlled

• Compact footprint

• Centralised control panel

• Mandrel with hinged support that helps to adjust film laterally on the run

OSAKO AND YOSHINO BOOKBINDING EQUIPMENT

As the local agent for Osako, Graph-Pak sells the company’s Tener and Tener Alpha and model 368 high-end saddle stitching machines new, or cost-effective certified factory refurbished options as well.

In November 2022 the company was appointed as the local agent of Yoshino, the largest perfect binding manufacturer in Asia, and is bringing Yoshino’s Sirius PUR Perfect Binder to the Australian market for the first time.

“The exciting thing about these two brands is being able to offer a true ‘quality competitor‘ to the Australian and New Zealand markets. Osako Seiki is already regarded as one of the best on the planet for new equipment and innovation,” Ralph said, explaining that the reason Osako also offers refurbished machinery is that it recognises the demand for high quality units that are attractively priced.

Osako said its Seiki-certified refurbished machines have been completely overhauled to be good as new and offer a full warranty. They are made from Japanese iron, which is believed to have a 100-year warranty.

Bookbinding equipment manufacturer Yoshino YM Machinery applies the technology and traditions inherited from its predecessor Yoshino Shuppan Kikai Company Ltd, which was founded in 1911. The company offers PUR binders, perfect binders, auto trimming, inline and auto trimmers offline, compensating stackers and more.

“Yoshino takes pride in contributing to a customer’s success by providing machinery and services to help them reach the optimum from their investment.

To me this is the perfect partner as the sale isn’t truly over until all the boxes are ticked,” Ralph said.

COL-TEC COLLATORS

Col-Tec manufactures highly versatile suction feed collators, booklet makers and associated optional equipment.

“Col-Tec collators are robust, and reliable and collate stock material and sheet sizes well outside the capability of other collators,” Ralph said, adding that the company has the most experienced and skilled collating machinery engineers in the world and offers solutions for all collating applications, including certified factory refurbished machines at “great prices”.

In fact, Graph-Pak has installed six refurbished Col-Tec machines in Australia and New Zealand in the last 24 months.

“There have been important developments in collating in recent times, which have the potential to revolutionise finishing. Indeed, I believe that many finishers will be both surprised and impressed with the technologically advanced Col-Tec collators now on the market,” said Ralph.

Most of the products that Graph-Pak distributes offer advanced productivity and automation capabilities. This is not surprising, Ralph concludes, pointing out that automation has been the company’s key pillar since its inception over two decades ago.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter