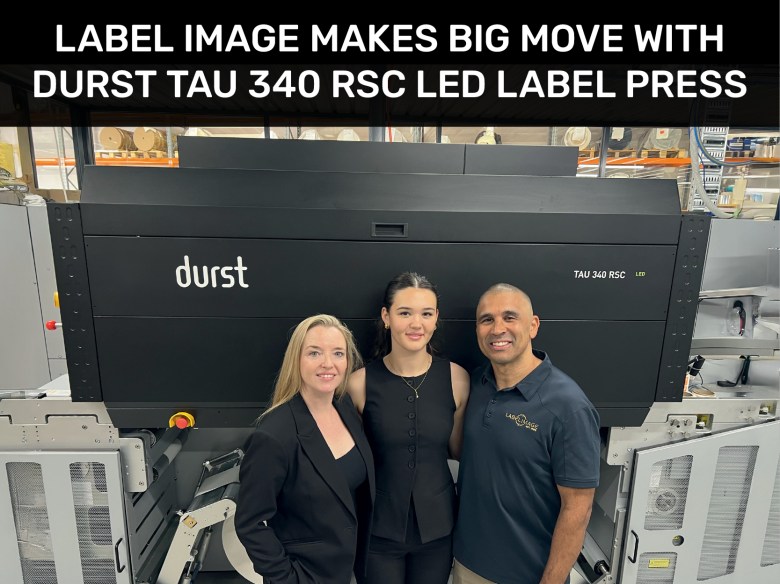

Perth-based Label Image first made its move from flexo to digital with a Durst machine, and has now installed a Durst Tau 340 RSC LED label press.

A new financial year, new premises, and a new Durst Tau 340 RSC LED label printer – it has been a busy few months for family-run Label Image in Perth.

Today, Label Image is an innovative label printing service company dedicated to providing high quality label printing. Australian owned and founded, the company has a rich history spanning more than 35 years, consistently serving businesses across both local and interstate markets.

The current management, led by Nick and Emma Godwin, arrived in Perth almost 10 years ago looking for a business to acquire within engineering and manufacturing.

“We used to run a small heating maintenance company in the UK and when we moved to Perth, we wanted to purchase an established business,” Label Image co-owner Nick said.

The couple ultimately chose to purchase the then 30-year-old company, Label Image, based in Osborne Park.

“The business was created in 1986, and we bought it from the original owners in 2016, as we felt this was the right move and the ideal industry for us,” Nick said.

Label Image continued to trade at the same location in Guthrie Street, Osborne Park, for almost four decades, until just a few weeks ago.

“We inherited the previous rented premises at Guthrie Street and have recently moved to our new premises at Carbon Court just over a month ago. Both premises are similarly-sized – but the big difference is we now own our new building, and we have a higher ceiling that allows us for more racking and higher capacity for storage, as well as a mezzanine that we added,” Nick said.

“Through the years, our network has grown to provide to all kinds of industries nationwide, giving us extensive experience in providing labels to any industry we encounter.

“Manufacturing on our own premises allows our graphic designers to consult directly with one of our highly skilled print technicians.”

Durst Oceania managing director Matt Ashman said Durst is very excited that Label Image has installed the Tau 340 RSC LED label printer, complete with LED curing and the new Durst HawkAI system delivering outstanding quality at 1200 dpi.

“Durst, as a business, is immensely proud to have Nick and Emma continue being a part of the Durst family. We are pleased to support the family business and have the confidence that the Tau 340 RSC LED will back their growth moving forward and across multiple vertical markets,” Ashman said.

“Durst Oceania labels and flexible packaging sales manager Graham Blackall has worked hard with Nick and Emma to develop a closer relationship and understand their business needs.

“We look forward to working with Nick and Emma, and the wider Label Image team as they introduce to their customers the tremendous output of this machine utilising the latest innovations unique to Durst.”

Shifting from flexo to digital

When Nick and Emma began working within the then recently acquired Label Image in 2016, the business was unproductive and lacking efficiency, according to the pair.

“When we purchased the business, we had three flexo machines and we soon realised that we needed to invest in a digital label printer,” Nick said.

“It was hard-going for us at the time – there were a lot more people to manage and there was a significant amount of work required to get output from those old flexo machines.

“It was 2019 when we decided to make the investment in digital technology. At the time, we researched several different models in the market, and we decided to go with Durst.”

The first Durst – Tau 330

The first Durst Emma and Nick purchased was a Tau 330 label printer, which Nick said transformed how Label Image operated as a business. At that time, the install was the first of its kind in Australia and the second Tau model in the country.

“Going digital with Durst was definitely the right decision for us,” he said.

“Digital printing not only suits the type of work we do, but it also suits the run lengths for our clients. We work with a lot of small to medium business and they are looking at various run lengths, and this is certainly more suited to digital over flexo.” Label Image timed the installation of the Durst Tau 330 perfectly in 2019, as this allowed the company to capitalise on the COVID boom in trade for label printers.

“At the time, it was a relatively significant risk for us financially, as it was only a couple of years after we purchased the business; but we were very fortunate to be in the right place at the right time,” Label Image co-owner and client services manager Emma Godwin said.

“COVID saw tremendous growth for our business. We found a lot of companies coming to us, needing work, as they were previously getting their labels overseas and with the lockdowns in place, needed to source their labels locally.

“After installing the Durst Tau 330 in 2019, we were quickly up and running and in a perfect position to win lots of new clients. The good news is, we have been able to retain most of these clients since then.”

The latest Durst for Label Image – Tau 340 RSC LED

As Label Image’s experience with Durst never faltered, Nick and Emma found themselves choosing Durst again when they were presented with an opportunity to elevate their business and purchase a new machine.

The Tau 340 RSC LED is a benchmark in productivity and flexibility with print speeds of 80m/min, a native resolution of 1,200 dpi by 1,200 dpi, and up to eight colour stations. Customers achieve flexo-like productivity in a 24/7 environment, where even challenging label designs with small negative text or skin tones are being produced with competitive TCO.

The Tau 340 RSC LED features an LED lamp system with instant on/off functionality, extending the life of the machine and amping power saving abilities by at least 32 per cent. It also comes with head reliability due to Advanced Autocleaning functionality.

In addition, the Tau RSC UV LED’s ink demonstrates high performance in resistance and durability. It is available in standard colour configuration of CMYK, orange, violet, and green, with an optional white, extending the colour gamut up to 95 per cent pantone coverage.

This also enables low ink consumption, high opaque white, and a broader application diversity – including a wider latitude in post finishing as it can work with laminates and overcoats.

“With the purchase of the new premises, we decided to upgrade from the Tau 330 to a new Tau 340 RSC LED label printer,” Emma said.

“The reason we upgraded from the Tau 330 to the Tau 340 RSC LED is, we needed more speed as the old machine was restricted to 40 linear metres a minute. The new machine features a different print configuration and, as a result, delivers 80 linear metres a minute.

“This helps with our larger run lengths for our major clients. It also allows us to print on CMYK + white which is also a huge advantage. While we feel as though we can cover most colours with CMYK, we are increasingly receiving silver ink jobs – so we need to put the white down for that.

“The graphical user interface of the new Durst Tau 340 RSC LED machine is also very easy to use and operator friendly. As a result, we are expecting to have every staff member trained on the machine – even our daughter Eliza, who is in Year 11 at school, has been able to operate the machine and print jobs. It is also very easy to maintain the machine as well.”

Automation is also a key functionality of the Tau 340 RSC LED as it comes with Durst Label Software tools that help users organise their production workflow to be more efficient and cost effective. This includes Lift ERP, Smart Shop, Smart Editor, Workflow, Analytics, and HawkAI.

Durst Oceania labels and flexible packaging sales manager Graham Blackall said, “Unique to Durst, HawkAI focuses on three primary themes: more applications, more automation, and less waste. It uses camera vision systems and artificial intelligence to automate print quality, significantly reducing waste and improving print quality.

“HawkAI goes one large step further than similar inspection systems available on the market. It corrects print mistakes, such as missing nozzles, inline and in real-time, without any setup needed or operator intervention.

“Additionally, it aims to significantly reduce setup time and waste, enhancing efficiency and an even more competitive total cost of ownership for the Tau RSC platform printers.

“The Tau 340 RSC LED also comes with analytics, that allow remote servicing as if the engineer was on site – an important feature for a business like Label Image due to remoteness of Perth from the Eastern Seaboard.”

The Tau 340 RSC LED installation

To maintain work across its broad client base, Label Image ran both the Tau 340 RSC LED and Tau 330 across both premises for a short period to limit the amount of down time.

“Before we traded-in the Tau 330, we kept it running while we were installing the Tau 340 RSC LED. As a result, we only had half a day of down time while we were waiting on our semi rotary finishing equipment to come across from the other premises,” Nick said.

“Overall, the installation of the new machine was very smooth, and Durst Oceania was very helpful with trading in our previous machine. During installation, the remote support we received from Durst Oceania was excellent and any issues were resolved very quickly.

“Graham and the team at Durst have been great to work with. Since Graham has come on board, we have received excellent customer service, and he has been on point with everything and helped us through the entire process. “He is very knowledgeable about digital label printing and the Durst machines. He has always been very responsive, and the entire changeover has gone a lot better than we actually expected.”

The servicing of clients

Like a lot of label converters, Label Image has a very broad customer base, with its spectrum spanning from the home entrepreneur to global recognisable brands.

“We do a bit of work across a lot of different industries – fresh produce and primary producers through to chemical companies, mining companies, and corporates,” Emma said.

“One of the beautiful things is, we get to meet a lot of different types of people – from grow your own farmers or beekeepers that make their own honey, right through to much larger companies.

“Some of our clients travel up to four hours to work on their labels with us, and we like our customers to know that our doors are open and that we are happy to sit down with them to go over their designs and provide assistance. “Depending on the time of year, we may have a fresh produce client in the winter and a pool chemical company in the summer, and because we have such a broad client base – if one business segment is not doing as well, we have found another industry will be busy – which helps us to have a steady flow of work.

“A majority of our business revolves around Perth and WA, but we also do work interstate and do trade work for other printers.

“Year-on-year we have grown the amount of work that we are producing through the business, and this has allowed us to purchase the new building and the new Durst machine.

“I don’t believe our business would be in this position if we were still relying on those flexo machines. We have noticed that the resolution of the new machine is better as well, and we hope that producing better quality labels for our clients can help us win new business.”

The next generation

The Label Image business currently employs nine staff members including co-owners Nick and Emma, as well as seven additional workers – with Nick and Emma’s daughter Eliza being the 10th employee in the company.

Eliza is still in Year 11 at school, but in her available time works as a production assistant and customer service manager – handling quotes and invoicing as well as operating the new Durst 340 RSC LED label printer.

“I really enjoy the creative and textural aspects involved with printing labels as well as handing over the finished product to happy customers,” Eliza said.

Eliza is also a qualified lifeguard and junior AFL player and aspires to work in the family business after she leaves school and obtains business qualifications at university.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter