It was drupa 2008 when the world first saw Screenʼs commercial introduction of its first entry into inkjet digital printing – the Truepress Jet520. Previewed at Ipex two years prior and OEMʼd to IBM as a transactional output printer, this launched Screen onto the path of transition from a purely CtP and prepress manufacturer, to a major force in POD digital print, with hundreds of installations worldwide, many model variants and now, a colour quality that rivals offset.

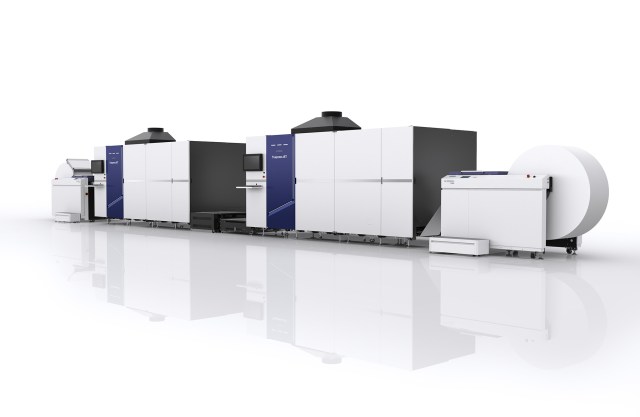

In finalising the development of its new Truepress JET 560HDX roll-fed digital inkjet press, Screen’s line-up for the commercial printing, book, direct mail, and publishing printing markets has taken a major upward shift into its first wider web roll feed machine at 560mm wide. All previous models have been 520mm webs.

It’s also faster and higher resolution and uses the remarkable proprietary SC2 inks and drying system for printing offset quality on standard offset stocks. This lowers the cost of papers from specially coated substrates engineered to receive aqueous inkjet inks and enables fast drying.

Screen says that the commercial printing market requires flexible print solutions with high-value economics because of more complex work, faster turnaround times, shorter print runs, multiple versions, late — stage revisions, and variable information—all demanded by today’s end customers. These requirements have created new business opportunities for high-productivity digital inkjet presses offering offset-like economics.

LOCAL FRIENDLY FACES ON SCREEN STAND, HALL 8A

Screen GP Australia’s managing director Peter Scott, who will be on Screenʼs stand at drupa 2024, says: “The introduction of the Truepress JET 560HDX is the culmination of years of experience and listening to customers in the high-volume digital printing space. At drupa 2024, the company has chosen a theme of ‘Creating a Future in Print – Tech x Irodori’ where visitors to our booth will gain valuable insights into the transformative impact of industry cooperation on the future of printing.”

Scott continues, “In Japan, Irodori literally means ‛to add colour’ but also implies ʻchange for the betterʼ. The 560HDX sums this up beautifully. The specifications and print samples I have seen are stunning. It’s no coincidence that our US branch has already logged two orders from existing Truepress 520 users, for the first installations of the 560HDX, with one exclaiming, ʻIt canʼt get here soon enough!ʼ It’s going to really help printers please more customers, more quickly. One of our US staffers says, ʻItʼs not just another new press to sell; it’s a whole new horizon for print.ʼ I can only agree with him and look forward to meeting with Australian and New Zealand customers on our stand at drupa to show how good it is, with live demonstrations.”

CHANGING REQUIREMENTS OF PUBLISHING AND DIRECT MAIL

The publishing market requires aggressive economics and high-quality as well as flexible format sizes to enable a growing number of companies to benefit from the capabilities of roll-fed, high-speed and digital inkjet press systems and workflows. Facing ever-shortening production runs and even ‘books of one copy’ requirements, book production systems need to be optimised for super-low to mid-volume production.

With direct mail, the market’s needs are for high productivity, flexibility to run lightweight uncoated papers as well as thicker, attention-getting, high-gloss self-mailers at low fixed and variable costs. These aspects are essential to help offset the rising cost of postage and other forms of distribution. Driving direct mail production costs as low as possible will encourage marketers to continue to use this valuable, tactile, and effective medium over saturated, confusing, and untrusted electronic communication.

In response to these changing market realities, Screen initially introduced its Truepress JET 520HD, 520HD+ and 520 HD-AD printers with Truepress SC and SC+ inksets. With this combination, Screen became the first manufacturer to provide a practical solution to printing directly onto offset-coated papers with a digital inkjet system and without the need for an inkjet media pre-treatment.

THE 560HDX OFFERS A 360-DEGREE VIEW OF PRINT’S FUTURE

Drupa visitors will be able to witness Screen’s latest development in this area, with the Truepress JET 560HDX, a unique system expected to drive further innovation in printing generally. The Truepress JET 560HDX can operate in a variety of print modes, enabling it to handle paper widths of up to 560mm at speeds of up to 150 metres per minute, with a maximum resolution of 1200 x 1200 dpi. It is also compatible with Screen’s SC2 Truepress ink.

This newly developed, high-optical density inkset allows printing directly onto offset-coated papers without any pre-treatment. The SC2 inkset’s special properties produce high vibrancy colours that ‘pop’ and have deeply saturated hues, as well as dense and neutral blacks for clearer printing of the very finest text and line work.

In addition, a new high-efficiency, intelligent drying system enables substrates with high ink loadings to be dried efficiently, thereby supporting superior quality and wide- gamut printing on a wide range of papers. The Truepress JET 560HDX is also equipped with a new, fast-start operating system that inherits and further improves on the Truepress series’ market-proven technologies. This system ensures flawless integration of all internal hardware and software as well as with both pre- and post- finishing equipment.

Screen anticipates that the Truepress JET 560HDX will become a benchmark contributor to the next generation of smart factories, where it is expected to introduce new economic efficiency, high-availability productivity, and print quality to satisfy the most demanding customer needs.

It will be a centrepiece of Screen’s exhibit at drupa 2024, from 28 May to 7 June in Düsseldorf, Germany and will also be displayed at Screen’s Inkjet Innovation Centres in the USA and in Europe, along with Screen’s other digital inkjet solutions for the labels and flexible packaging sectors.

MORE INKJET INNOVATIONS FROM SCREEN ON DISPLAY AT DRUPA 2024

drupa will also see inkjet innovations from Screen in the sheetfed SRA3 sector, a new high opacity mono ink for bookwork and also Labels and Flexible Packaging.

drupa 2024 will be an opportunity for Australian and New Zealand printers to get a first look at a fully featured model of its Truepress JET S320 sheetfed printer, a cooperation with Kyocera Document Solutions, announced and previewed at Printing United USA in October 2023.

The S320 also uses Screen’s Truepress ink SC/SC+ technology for ink compatibility with standard coated papers and unrivalled colour vibrancy. Billed as ‘the offset printer’s digital press’ the S320 will be offered without the traditional cut-sheet ‘click charge’ model and is seen as ‘completing the loop’ of CtP-offset; high- volume digital and short-run digital sheetfed production.

MONO NOT FORGOTTEN

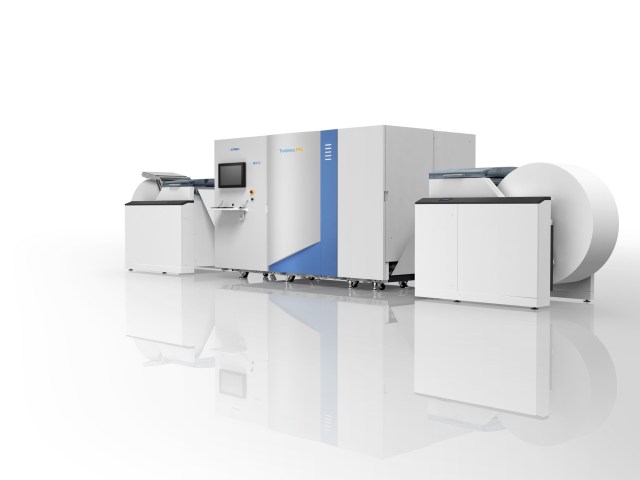

It’s easy to get carried away with brilliant colours but the market for monochrome books and paperbacks in short runs is still strong. At drupa 2024, Screen aims to redefine monochrome printing standards to unprecedented heights with its Truepress JET 520HD Mono running the new SU Black ink with increased levels of optical density for uncoated or inkjet coated paper. Engineered as the next-generation monochrome inkjet press, this innovation is optimised to print directly onto offset-coated papers.

The well-established Truepress 520HD Mono inkjet press goes beyond the sharp replication of text characters and barcodes, introducing a new level of richness in gradations for any image and reliable variable data printing capabilities. This high-speed inkjet digital press is equipped with greyscale printheads that masterfully control droplet deposition, reliable web transfer, and tension control, ensuring precision even with thin papers as light as 40gsm.

Applications such as pharmaceutical leaflets, direct mailing overprints, on-demand book printing and instruction leaflets also benefit from denser, sharper blacks.

LABEL PRESS SUCCESS JOINED BY FLEXIBLE PACKAGING

Screen’s well-established Truepress Label 350UV SAI inkjet range of UV presses, sold throughout Australia and New Zealand by Jet Technologies, will also be featured at drupa. A newly developed digital primer unit for label printing will be demonstrated, broadening the range of label materials that can be printed.

The L350UV and SAI range has proved extraordinarily successful in Australia and New Zealand and, indeed, globally, delivering a high-uptime and fast digital label press to packagers and converters. Using inkjet UV, the L350 series is faster than most other digital methods and can be supplied as either a stand-alone digital solution or integrated inline with flexo and converting modules from Nilpeter to create a total integrated solution that can include semi-rotary die-cutting, hot and cold foil, high-build varnish, doming, lamination, matrix stripping, video inspection and more.

The hybrid model is based on Nilpeter’s famous FA-line converting and includes the Screen digital module, which can print up to seven colours, including white.

One advantage of Screen’s L350UV SAI ‘S’ model is that, when equipped with white ink, its speed is still a healthy 50 metres per minute – a very small change from its normal 60 mpm. Coupled with proven high uptime and durability, this makes the L350UV SAI the most productive narrow web digital press overall. In fact, even older, slower models are in high demand when traded in for the new SAI series.

BACK TO SUSTAINABLE PAPER FOR SOME PACKAGING

With increasing concern over microplastics and fossil-resource-based materials, Screen was one of the first to introduce a digital-flexible packaging press capable of producing high-value paper packaging.

The Truepress PAC 520P inkjet press uses water-based food-compliant inks for paper packaging, which will also be demonstrated at drupa to help converters and brand owners achieve their sustainability goals. The company intends to present a range of label and packaging samples utilising eco-friendly base materials, introducing sustainable solutions and productivity-enhancing options for digital inkjet printing of small and medium-lot jobs. Screen personnel will elaborate on how these solutions present substantial new business opportunities during drupa presentations.

AQUEOUS DIGITAL FLEXIBLE PACKAGING HAS ARRIVED

The long-awaited Screen Truepress PAC 830F inkjet system for flexible packaging films will also be shown at drupa. This will provide an opportunity to explore the various features of this press, including its innovative design, and delve into the intricacies of achieving digital printing on filmic flexible packaging using water-based food-compliant inks.

The Truepress PAC 830F water-based inkjet digital press has been specifically designed to produce short printing runs in a cost-effective manner while providing total flexibility to operations. This new single-pass industrial inkjet digital printing press is a fit-for-purpose printing solution that allows packaging converters and brands to capitalise on emerging trends in flexible packaging, boosting profitability in short-runs.

Running at 75m/min, its CMYK and Heavy White water-based inks fully comply with the standard food safety regulations. At drupa, packaging printers will have the first opportunity to witness the printing module of PAC830F for the first time and see their sustainable future take shape!

DID SOMEONE SAY CTP?

After thirty years of developments, computer-to-plate may seem mature, but Screen – recently surpassing 25,000 devices shipped – has never stopped innovating. It will present the new PlateRite HD 8900NII, an eight-page CtP system and the latest addition to its PlateRite series.

As a solution provider from print data creation, Workflow (EQUIOS) to printing, Screen will present its unique digital and offset hybrid solution to support various applications and run-lengths integrating digital web-fed inkjet presses, sheet-fed presses, CtP, software, colour management and over eighty years of deep experience – all at drupa 2024 in Hall 8A.

Local MD Peter Scott says, “Screen extends a warm welcome to all Australian and New Zealand visitors to drupa to learn more about its vision for the future of printing on multiple levels. I have attended many drupas and other international trade shows, and I don’t think I have ever been so excited about the new technologies to be released and new key learnings to be gained. After all, it’s eight years since the last drupa in 2016, and the innovation will be twice as impressive!”

Screen can be visited in Hall 8A, stand A03 at drupa 2024.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter