This feature first appeared in the July 2025 issue of Australian Printer

Business leaders have varying personalities. While extroverted personalities are more visible in

the public eye, they don’t necessarily have an advantage over introverted leaders. These silent entrepreneurs keep their heads down and work smart in gaining business.

Cyber Australia managing director Bernard Cheong is one of them. Within a span of more than 20 years, Cheong has silently and humbly turned Cyber Australia into one of the largest printing distributors in the Asia Pacific region. Real estate is another of the company’s key assets.

In Singapore, the company recently relocated to a new office and began leasing out its former multi-story premises, which it owns.

“Cyber’s assets are mainly in real estate. We’re fortunate because we’re asset rich – we have our own building in Australia and the four factories we own in Malaysia for showrooms, a refurbishing centre, warehousing, and a candy plant spanning five hectares, are all owned by us. We don’t have any additional overheads for our real estate, allowing us to focus on what matters most – our customers,” Cheong said.

Cheong leads Cyber Australia, but his older brother John now heads up the wider Cyber entity ever since their dad Herbert took a step back from the business a few years ago due to health reasons. Cheong’s other brother, Paul, also works within the business as sales director.

It’s hard to speak of the origins of Cyber Australia without detailing the lesser-known fact that Australian Printer is intertwined with the company’s first foray into this region.

It all started with a relationship between Brian Moore and Cheong. Moore, who was formerly publisher and sales director at Australian Printer, is a long-standing part of the magazine’s 75-year history

– 24 years and counting, to be exact.

During his time with Asian Printer Magazine in Singapore, Moore established a strong working relationship with Cheong and Cyber, a then Singapore-based company. That professional partnership naturally fortified when Moore returned to Sydney to run the Printer Media Group, parent company of Australian Printer.

A few months later, in what was just a simple discussion about the Australia and New Zealand printing markets between Moore and Cheong, Moore planted the seed to what has now grown into Cyber Australia, which holds the RMGT agency in this region.

“It was actually Brian who sparked my interest in setting up Cyber Australia,” Cheong recounted.

“I had known Brian from his time in Singapore, and we never miss an opportunity to catch up whenever he visits the country. We were once having a simple conversation about the A/NZ markets shortly after he returned to Australia, when Brian asked me if I knew much about that space.

“With Cyber having a big play in only the Asian market at that time, I replied that I didn’t know much about it; I thought Australia was a ‘sleepy town’. Brian then told me ‘You should check it out, because there’s a world of opportunity’.

“I did my research and made a few trips over to study the A/NZ printing landscape and true enough… there was an untapped opportunity for Cyber to make its mark in this region. The Ryobi distributorship was also available, so we took on the challenge.”

The rest was history.

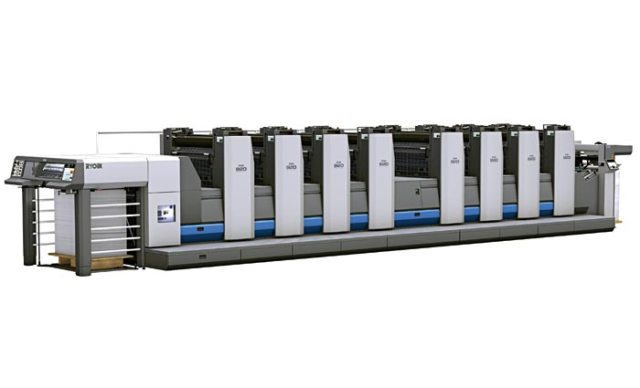

Cyber Australia was established in 2004, with the company showcasing several Ryobi presses at PacPrint 2005.

“At PacPrint 2005, our first PacPrint, all major exhibits were sold,” Cheong said.

In 2009, Cyber Australia first unveiled the Ryobi 920 series in its Singapore showroom. The 925, a SRA1-size five-colour offset printing machine, was first purchased by CMYKhub in Australia sight unseen as a vote of confidence in Cyber and Ryobi.

“We truly appreciate the partnership and confidence CMYKhub has in us. The superior cost performance of the 925 led to more presses being purchased from the group over the years,” Cheong said.

“This includes Australia’s first 925D five-colour with UV coater, the first 928P LED 8-colour convertible perfector with LED system, and the new 970PF-8 LED with PQS-D A1-plus-size 8-colour convertible perfector with LED and Smart-Automatic Printing (SAP), featuring non-stop automatic registration and colour control and inspection. CMYKhub bought a total of 15 offset printing presses from us.”

In 2010, Ryobi and Mitsubishi came together to form RMGT. The integration of the two product lines enabled Cyber Australia to bring to market the best of both worlds, giving the business an

added advantage.

Through the years, order numbers increased, and Cyber Australia became a household name.

The Cyber of today

Cheong provided an update on Cyber Australia’s more recent business, saying the pandemic actually ended up being favourable for the company.

“In a single year, during the COVID period, we experienced the best business performance in our history in Australia,” Cheong said.

“Because shipping was an issue for printers during COVID, the Made in Australia movement resulted in more products being produced locally. This meant printers needed efficient machines to deliver quality solutions, and many turned to us as their trusted technology provider.

“Every cloud has a silver lining – you’ve only got to look for it in the right places.”

One of the more recent installations was at CCS Media Packaging, which installed a new RMGT Ryobi 970 seven-colour press with aqueous coating in 2024, bringing in the final piece of a 12-month, multi-million dollar investment.

“CCS is a unique client of ours. They used to print for record companies, but with music now going digital, the need for prints for CDs and other related materials became obsolete. So, the company pivoted into the food packaging space and needed the machinery to support production,” Cheong said.

“But now, with record labels at boutiques making a comeback, it has become the icing on the cake for CCS because they have already been involved in the music industry.”

Of late, with the prolific growth in packaging, Cheong finds the number of print service providers purchasing machines from Cyber Australia specifically for packaging purposes has escalated.

“Half of our installations are now to companies that have taken on packaging work in addition to their printing capabilities,” he said.

“This was, again, brought on since COVID, when peoples’ purchasing patterns shifted from in-store to online.”

In New Zealand, the company is currently in the process of installing two presses.

“In New Zealand, a lot of print service providers’ equipment are getting old. Their hands are being forced to either update their machinery and continue operations, or close down,” Cheong explained.

Across Asia, most of the company’s sales come from Malaysia and Vietnam.

“There’s greater demand for machines in the developing markets in Asia as they invest a lot more than the developed markets. This is because most of the work is outsourced to printers in these countries,” Cheong said.

“When COVID hit in Malaysia, for example, business did stall momentarily but it was the first to pick up because the country sees a large production of latex and with the requirement for latex gloves, our print service providers needed to print glove boxes rapidly.

“Since COVID until now, the Malaysia market hasn’t stopped – in fact, it’s been really strong for us. With Donald Trump slapping tariffs on China, I think it’s only going to fuel the Malaysian market to

be even stronger.”

The move back to offset

According to Cheong, Cyber’s customers are making the move back towards offset equipment as technology has made offset printing more affordable than before.

“For non-collated products, we have clients that were strong digital users for more than a decade embark on an offset journey because they find it cheaper to print on offset. Offset was dying because the last major adoption in that space was CTP. But now, with modern offset printing equipment, it is equally easy to print on it because everything is automated,” Cheong said.

“With digital, it’s all click charge – you pay for every sheet. With offset, you pay for the commodity, which is ink and plates. They’re cheap.

“So, RMGT’s R&D division focuses heavily on digitising offset equipment. The focus is very much on the mechanical engineering – improving reliability, increasing speed, and simplifying make-ready times and staffing requirements.

“In fact, the company used to manufacture some digital machines, but when comparing the cost of print to automated offset presses, it found that printing on automated offset was still cheaper.”

One example that Cheong mentioned was US-based Pacific Printing. Previously, a lot of the company’s short-run work was digital. But, the ability to get to colour quickly enabled it to move a lot of that work over to offset, changing the capabilities for the business in terms of what it can gang-run and put on press in a short amount of time.

But even with the change in market demands, the core of Cyber remains the same.

“Our focus from when we first started until today is the same. We are very much a customer orientated business that evolves together with our customers. We are not fixated on any single market – whatever the customer wants, in whatever direction that they move, we are there for them,” Cheong said.

“Our customers are our compass for change – they show us the direction, and we adapt accordingly.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter