Three 3D printed not so little pigs proved a major Lunar New Year drawcard in January with the creations attracting thousands of onlookers to a Sydney shopping centre and a whopping 10.5 million hits on Chinese microblogging site Weibo.

The idea to use three 2.7m high and 1.2m wide pigs that could come alive in augmented reality to celebrate the Year of the Pig at World Square was devised last year by cultural art curator Claudia Chan Shaw at the request of World Square.

Sydney digital agency Vandal created the digital files so the pigs could be beamed onto a massive forecourt TV screen giving passersby the feeling they were actually dancing with the pigs, but World Square management wanted a physical presence as well.

Turning the pigs into a physical reality was where Will Colhoun, of Big Kahuna Imagineering, in Sydney’s Rozelle, came into the picture. He wanted to retain the digital legitimacy of the pigs so opted for a 3D printing process, as opposed to having them hand sculptured.

“The pigs wouldn’t have been identical to the digitally animated files if I put them into human hands. They would have had a translational loss of fidelity,” Calhoun told ProPrint.

“But it was very time consuming to bring them up to the finish I wanted.”

Realising his 3D printing capabilities weren’t enough to produce the pigs, he sent the job north to Studio Kite, an animatronics and special effects company based at The Pocket, near Byron Bay, in northern NSW.

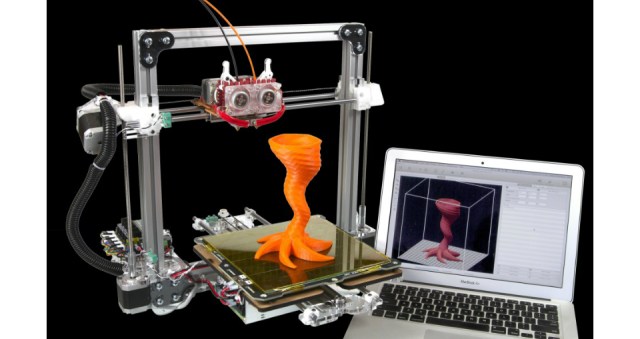

Studio Kite, using their self-created 3D printer, produced each pig in a series of parts, which Colhoun then put together, properly finished and painted the telltale pink.

In all it took 45 hours to print all the pig parts with Colhoun and his team of finishers at Big Kahuna Imagineering spending three weeks over Christmas putting them together and turning them into the shiny and perfect look they held on display at World Square.

Studio Kite owner Steve Rosewell built the 3D printer, called CADzilla. He says after many years of intensive use of 3D printers for building animatronics and models he decided to pursue building a larger machine that could handle much bigger and heavier jobs safely, quickly and with far less cost and environmental impact.

“It’s a delta style which has four motors instead of three like you see everywhere else, this helps considerably with space it takes up for the size of object it can print, which is about 2.4 x 2.4 x 2.4 m, it also means the machine is capable of much faster printing speeds” Rosewell told ProPrint.

“Having the fourth motor also means that if one of the motors decides to do something wrong the other three won’t let it, making it much safer to be working around, the design also is very lightweight so even if it did hit you it wouldn’t do much damage because there’s no big moving gantry like a lot of the other machines of this scale.

“So we just pushed along with that design and used a lot of high end hardware and it far excided our expectations on performance"

“Getting all of the software together was quite difficult. We had to fly a Prodigy robotics guy from Austria over to write all the software. I was quite relieved when I saw it moving so well on that first day.

“There’s been a few modifications here and there. On the next machine we are starting to build to sell there will be numerous improvements. There’s already a big chance it has been sold to a big prop company."

Suzannah Nicholson, senior marketing manager at World Square, said the pigs were a massive hit leading to the decision to keep them on display for the rest of the year.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter