A new wide-format printer purchase from Agfa has elevated design agency Popart’s client offering to new heights.

Established in 1998, Popart in Melbourne’s Cheltenham delivers tailored solutions for its clients’ retail display needs. The designers and project managers at Popart have a robust understanding of retail and deliver creative solutions from in-store fixtures to promotional counter units.

Before Popart moved to purchase its first Agfa printer in October 2023, it sent all its wide-format printing needs off-site. The new printer has transformed the way Popart does business. An entire section of its office was redesigned to house the equipment in its new air-conditioned space equipped with an automated sliding door.

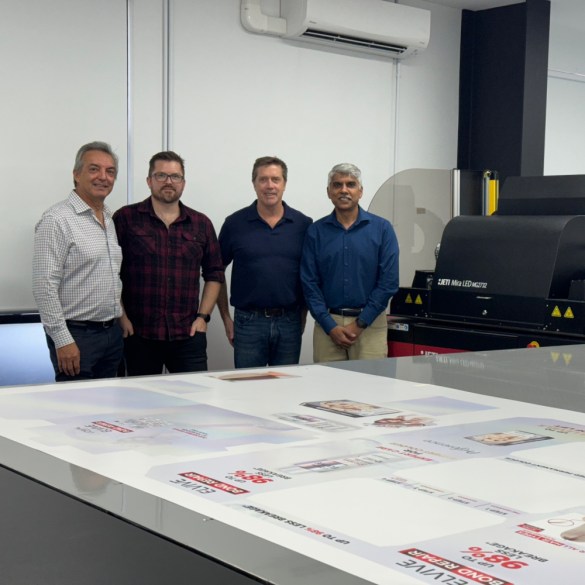

Sprinter spoke with Popart’s group managing director, Colin Robertson, about his new Agfa Jeti Mira MG2732 HS LED machine, and received a full demonstration of its impressive capabilities.

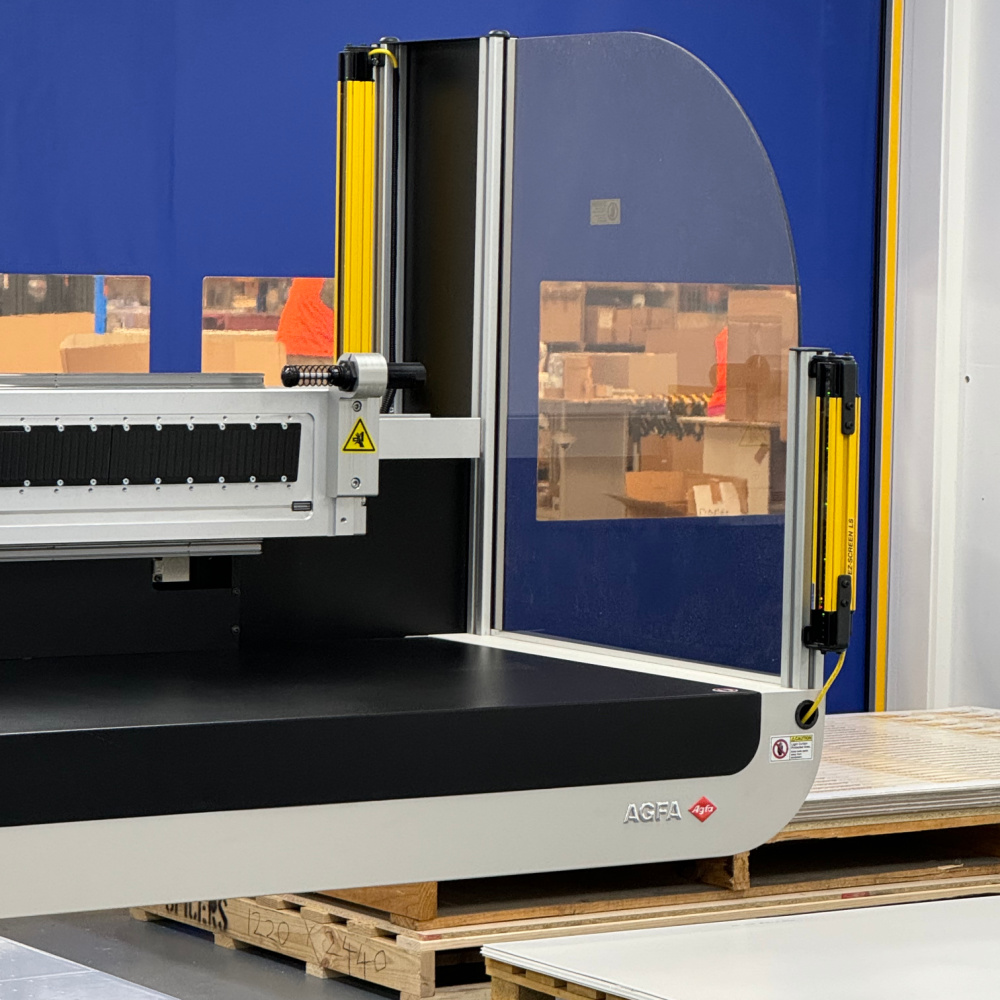

This award-winning flatbed printer is a moving-gantry printer that relies on UV LED curing to offer impressive print quality with a wide variety of media. It accelerates the printing process to 248 m²/h, with a dockable roll-to-roll extension, up to 2.69 metre wide prints and 3D Lens Technology.

Why the decision to invest in a printer?

We are not manufacturers; we are graphic designers. We outsourced our printing needs. That is still the case for our high-volume jobs, but we are using our new Agfa for our bespoke complicated stuff that the big operators can’t do or, let’s face it, don’t do because it’s a pain.

What was behind your decision to choose the Agfa product?

There were two frontrunners, both flatbeds, but this is a fixed bed machine, so the media sits on the bed and is sucked flat. Because we do a lot of corrugated work, it doesn’t sit well on the hybrids because the bed is moving back and forth, so it’s never completely flat. The image quality is higher here. This kind of printer model is better for heat-sensitive media such as paper products, and this is all paper products. For this application, this is the best solution. Plus, we chose this one for the speed and the high level of quality, including fine print for the price.

How did you discover it?

Through Adam Leach, our print production manager. We had been working with him for many years through printer companies. We contacted him, and he was looking for new opportunities. He also recommended Rashed Chughtai from Agfa as a supplier.

We wanted a print-and-cut solution. We want our machines to talk to each other. As we say in our industry, one throat to choke. If a printer’s not talking to your cutter and things aren’t going well, you don’t want two or three different vendors to deal with. Rashed has been fantastic. We really couldn’t say enough about the excellent service we have received from these guys.

What was this room before it was your printing room?

This print room was a whole series of offices. Imagine seven or eight offices with steel posts and all sorts of stuff. It was a major engineering exercise. These guys were manufacturing the machine as we were manufacturing the room at the same time. It all came together nicely. The reason it’s in a room like this is because they don’t like temperature variations, so it’s environmentally controlled, which means that everything produced is consistent and has the best possible result. My favourite part is the automated sliding door to the warehouse.

What are the features of the printer you were attracted to?

One of the selling points is the tandem printing mode. There are two separate Lay corners so that you can print on one side of the bed, and while that’s going, you can load on the other side and print in reverse. It delivers consistent printing without any downtime of unloading, loading and waiting. When you unload and load the sheet, there is no loss of time.

Then there’s the lay edge. It’s a series of pins that, when popped, create the lay edge so we know what we are working with. Every single sheet is the same for when we multi-cut them. This is critical. On hybrid models, you don’t have these accurate layers of reference.

What’s the response from your clients?

Very positive. We opted for the varnish and white ink in the machine so we could print a full varnish coat over a print or do a spot varnish. It makes an image pop.

Same with white, we can do a spot white if we want to print on transparent material, or we can do white lettering with an image next to it.

And the output?

27 sheets an hour. It’s not a massive part of our turnover, but it’s vital to producing a promotional display that pops. It’s high quality when the client is looking for something really special. We are not going to become printers as such; we just want to be able to print our work in-house, particularly the prototyping. Prototyping is a massive part of our business. Clients want to see what a job looks like, which is fair and reasonable.

When I first started as an industrial designer, we used to do sketches with coloured pencils and spirit-based markers. Clients would only see the real thing once it was offset or screen printed. We could show them the film, but we could only show them a final example once we had one. There would often be problems in translation between what the client thought they were getting and what they got. Now, it’s full circle. What they are seeing is what they are getting.

SMARTECH is the exclusive distributor of Agfa in Australia.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter