Three Australian printers signed orders with Ferrostaal at drupa for the new digital Komori Impremia NS40, the Landa driven B1 sheetfed nanographic press, while online printer Vistaprint will also get one through a mega 20 press deal with parent Cimpress.

The trio comprise the country’s biggest sheetfed printer Blue Star, together with trade print shop Hero Print, and an un-named packaging business. They will join CMYKhub which signed at the last drupa, and Vistaprint in Melbourne.

The orders can more properly be regarded as taking an option to buy a press when they are launched, at a date yet to be determined, but which will likely be at least two years away and possibly further.

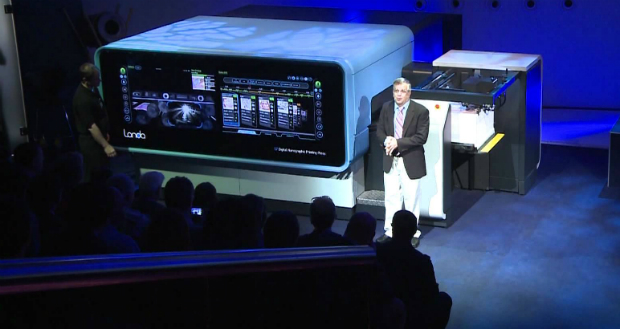

At drupa the Landa presses on the Komori booth and on Landa’s own booth were running, but the prints had no fine lines, text or sharp edges. Those in display produced under lab conditions in Israel and shown at drupa did however.

It is reproducing those lab prints in a commercial environment that is taxing the Landa scientists, of whom according to Benny Landa there are now 500 beavering away.

Nonetheless the Aussie trio signed up, taking 15 per cent of the 21 orders Komori took at drupa, confirming Australia’s reputation as early adopters of new print technology.

[Related: Landa offers nano orders at drupa]

Carstern Wendler, managing director of Ferrostaal which supplies the Komori Impremia S40 in Australia says, “Congratulations to the three businesses who have ordered the Komori Impremia S40. The press will break new ground with its high speed and high quality, and will enable printers to offer more to their customers. Buying from Komori assures them of the high level of service that our customers receive.”

Komori is Landa’s partner, it provides the chassis, feeder, transport and delivery, while Landa supplies the print heads and blanket technology. The Komori version of the press is specified to run at 6,500 sheets an hour, half that of the Landa version.

“The Impremia S40 is built on Komori hardware, which as everyone in the print industry knows is a robust, reliable, precision, high quality platform. To ensure that the quality is at the level our customers require Komori will manufacture the press at 6,500sph,” adds Wendler.

Landa introduced its nano technology at drupa four years ago, this time around he had fewer presses, a different design, and the same optimism that the nano presses would come to market.

Benny Landa told journalists the first beta site machines will go in at the middle to end of next year, with commercial launch to follow.

Nano printing technology uses tiny droplets of ink which are fired onto a blanket, and then transferred to the stock, which Landa says will be any conventional offset stock. The droplets then sit on top of the stock rather than sinking into it, which says Landa gives the quality and vivid reproduction.

[Related: drupa 2016 news]

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter