Canon has announced the development of sheetfed single-pass digital corrugated press.

Canon has announced plans to become a major player in the labels and packaging category announcing a strategy in the corrugated and folding carton markets.

In an announcement made at the Pre-drupa Global Press Conference held at Messe Düsseldorf, Canon confirmed its commitment to become “a significant, trusted partner to the label and packaging markets, and show a new digital press and product concepts that confirm its clear progress towards that goal. Indicating the importance of labels and packaging as strategic areas for growth, a dedicated zone on the Canon stand will feature live production of label, corrugated and folding carton applications”.

“As evidence of its commitment to expand into the corrugated printing market, Canon will introduce its concept for a sheetfed single-pass, industrial-scale digital corrugated press, targeting corrugated packaging converters and designed to combine offset-like print quality at a 1.7 m print width, productivity of up to 8,000 sqm/hr and new levels of cost-efficiency. A 3D model, print samples and technology animations of the system will be shown on the stand at drupa,” the company said.

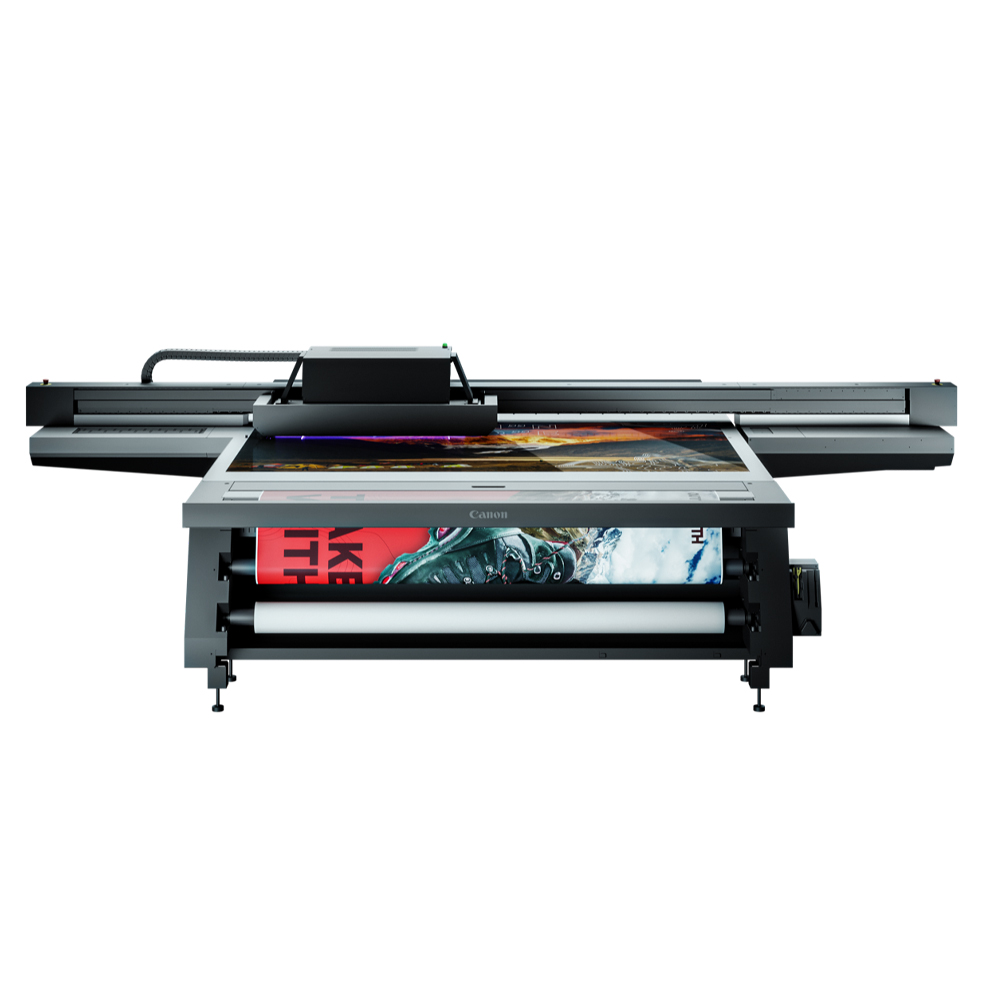

“Visitors interested in digital printing on corrugated can see live production of packaging prototypes and short-run promotional packaging on Canon’s large format Arizona and Colorado printers. For packaging converters and print service providers, these solutions enable personalised, short-run, on-demand packaging production. The new Arizona 2380XTF FLXflow technology flatbed printer – also on display at drupa – will print a variety of display and packaging applications on a wide range of media, including corrugated. White, varnish and the opportunity to print elevation up to 4mm with PRISMAelevate XL give full design freedom for high-quality packaging and packaging that can be “read” by the visually impaired.

“A UVgel Print Factory, comprising a Colorado M-series roll-to-roll printer and a Fotoba Jumbo Roll JRL 170 feeder and JRR 170 Rewinder, will be shown printing on a liner material for later lamination to a corrugated base to create a high-quality printed package, as a digital alternative to conventional litho lamination. Replicating the litho lamination process with digitally printed liner material offers short-run, high-quality packaging that can be personalised or versioned, while the durability of UVgel prints means that additional top coat lamination is not always necessary. With the FLXfinish+ technology’s ability to achieve matte or gloss finish in one print without changing ink or media, customers can achieve a premium look and feel without any extra cost to the print service provider.

Since its acquisition of Edale in 2022, Canon has also started to establish a presence in the folding carton market. At drupa, an inline folding carton production process will be shown, taking pre-printed reels which will then be embellished live on the Edale FL5-Single-Pass Carton Production Line, adding either cold foil, cast & cure or varnish. The carton will move inline to the Edale FDC600 flatbed die cutter for cutting, creasing, braille/embossing, and waste stripping, ultimately delivering finished carton blanks in a single pass.

Folding carton print samples digitally printed on Canon presses, such as the toner-based imagePRESS V1350 and the varioPRINT iX3200 sheetfed inkjet press, will also be available on the stand.

Further demonstrating its intention to become a key supplier to the packaging market, Canon will provide its outlook on industrial-scale, digital sheetfed folding carton production, targeting converters who are interested in exploring the benefits of digital print.

Jennifer Kolloczek, senior director, Marketing & Innovation, Production Print, Canon EMEA, comments: “While flexo and offset printing processes are suited to the mass production of high-volume jobs, converters are now struggling to maximise plant productivity in the face of more frequent reprints, short runs and versioning, as brand owners create ever increasing numbers of SKUs – all in the context of significantly reduced turnaround times.

“As the global leader in high-volume production inkjet, our digital presses already operate side-by-side with analogue equipment in complex, high-volume, industrial environments across a variety of commercial print segments, giving us a good understanding of converters’ requirements. Our market-leading inkjet expertise, experience with challenging substrates, and extensive track record of building high-performance production lines, together with the additional insight gained from our acquisition of Edale, mean Canon is ideally placed to help label, corrugated and folding carton converters to gain competitive advantage by increasing operational effectiveness and differentiating their offering,” she said.

“Working with a diverse range of technology partners, we are highly proficient in devising complete end-to-end solutions, hybrid workflows and smart automation. Our systems, together with Canon’s ongoing expert technical and business development support, have enabled hundreds of businesses worldwide to unlock additional productive capacity and tap into profitable new revenue streams and business models. We’re committed to extending those same advantages to label and packaging converters.”

Canon will also show the new LabelStream LS2000 digital label press at drupa, the first public preview outside Japan. Based on innovative Canon technologies and designed for industrial-scale label printing, the LabelStream LS2000 is Canon’s first water-based inkjet label press. Available in the EMEA region in 2025, the device prints CMYK plus white on self-adhesive substrates, with a new ink set designed to comply with food safety standards. Visitors to Canon at drupa will be able to see live label production on paper and film media, printing the labels on the LabelStream LS2000, which are then ready for varnishing, die-cutting and slitting on stand on a nearline converting device from Grafisk Maskinfabrik. Print samples from the Canon group company Edale FL3 flexographic label press will also be available.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter