Durst has confirmed that it has already received two initial expressions of interest for its new unmanned robotics systems recently launched at FESPA Munich.

Durst Oceania managing director Matt Ashman said while pricing on the dual unmanned robot systems is not confirmed for the Australian market, it is not an issue because customers see this as adding value to their business and they want a print factory concept that is potentially integrated with a cutter as well.

“This then provides the holy grail of material cut and stacked on a pallet that is ready to ship out,” Ashman said.

“We can then automate the workflow as it comes directly from the customer – it is pre-flighted, it is checked, it goes straight to the press, straight to print – and done.”

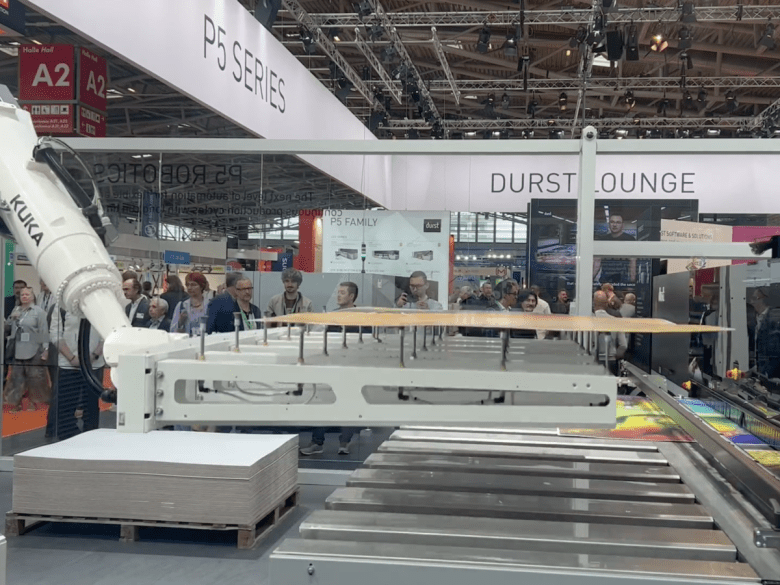

The introduction of an unmanned robotic system on the Durst stand stole the show in terms of visitor engagement and interest at the recent FESPA 2023 exhibition in Munich.

In a move that was not known to many people within the company, let alone the industry, the unveiling of the Durst P5 Robotics concept followed a year of research and development.

According to Durst, the decision to introduce the P5 Robotics concept was the logical next step following the introduction of the P5 Automat – the company’s automated feeder/stacker system for flatbed printing.

“Durst is igniting the next stage of automation with P5 Robotics for flexible and continuous production cycles with long run times,” the company said in a statement.

“At the heart of the P5 Robotics is the flagship P5 350 HS D4 hybrid printing system, whose feeder/stacker unit is formed by two Kuka robots to handle the unmanned production of a complete shift.

“The robots, modified and programmed by Durst, can pick up media from different pallets with a height of up to 180cm, feed them and then stack them again separately. In the process, the printed media can also be turned 180-degrees for reverse-side printing and fed into a second printing system. P5 Robotics can also be expanded with third party solutions or finishing systems.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter