Fujifilm BI Australia has become the first authorised distributor for Vivid Laminating Technologies in the Asia Pacific region, specifically for the Australian market.

The company made the announcement today at PacPrint in Sydney this week.

The partnership leverages Vivid’s expertise in laminating and print finishing solutions to address the growing demand for finishing technology across Australia’s packaging, labelling, and print industries.

Fujifilm BI Australia head of graphics communications Steve Fisher said the company recognised the opportunity to enhance its cutsheet finisher portfolio by addressing a market gap for die-cutting solutions as customers increasingly look for more cost-effective solutions for a broader range of applications.

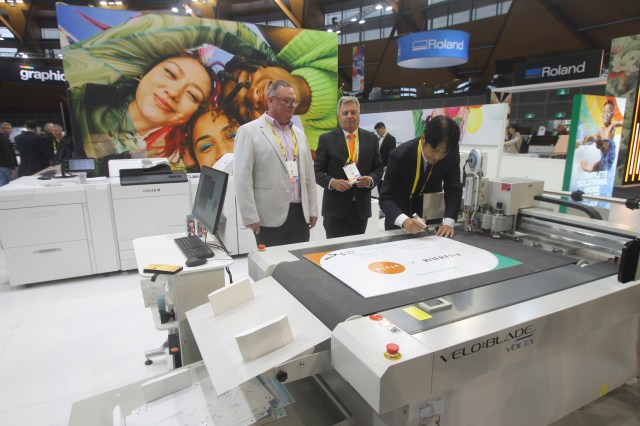

“We’ve been looking for a technology for the Australian market that can set us apart from other players in this field. And today, we’re signing a strategic, exclusive partnership where Fujifilm BI will be the distributor of the new Vivid technology,” Fisher said at PacPrint 2025.

Fujifilm BI graphics communications head of Oceania and senior general manager Yoshitaka Nakamura said, “Vivid’s reputation as a trusted innovator in laminating and print finishing technologies, combined with its competitive pricing structure, made it an ideal partner for our market.

“Its product range ideally complements our solutions, enabling us to deliver high-value print and finishing capabilities to our customers across Australia.”

Vivid export director Bruce Cozens said, “Partnering with Fujifilm Business Innovation Australia marks a significant milestone for us as we expand our footprint in the Asia Pacific region. We are excited to bring our innovative and high-quality unique patented solutions to the Australian market, empowering businesses with the tools they need to enhance their operations and add value beyond print.”

The Vivid products Fujifilm BI Australia will bring to Australia include the VeloBlade Nexus wide-format digital die-cutting system and VeloBlade Volta sheetfed production digital die-cutter.

The VeloBlade Nexus comes in two models – the 1816W and 2516W – and is suitable for a variety of applications including rigid signs and display, POS, banners, and packaging.

As for the VeloBlade Volta, it is available in two configurations, Volta 69+ and Volta 1070+, and can be used for applications like short-run customised flat sheet POS, label and packaging, and cards. The VeloBlade Volta is displayed at PacPrint 2025, along with a range of other technology.

PacPrint 2025 marked the company’s debut as One FUJIFILM, following the unification of Fujifilm BI Australia (FBAU) and FUJIFILM Australia (FFAU)’s graphic communication divisions, under FBAU.

Its theme for the tradeshow, ‘One Fujifilm: Complete Solutions, More smiles’ aims to reinforce its new identity and showcase its extensive portfolio that encompasses analogue plates and chemicals, pre-press, digital, and associated workflow solutions.

FBAU also took to PacPrint to launch the Acuity Triton today.

The Acuity Triton, which was first shown at drupa last year, is powered by AQUAFUZE ink technology and is a new roll-fed printer platform that meets a multitude of market requirements by combining the benefits of LED UV and water-based inkjet technologies.

The Acuity Triton brings together two titans of the wide format inkjet industry. The hardware is manufactured in Japan by Mutoh. The AQUAFUZE ink has been developed and produced by FUJIFILM, drawing on its unparalleled track record of ink innovation.

Acuity Triton is the ideal pairing for the AQUAFUZE ink technology to support its vast range of applications with excellent print results for this market space.

AQUAFUZE technology meets a multitude of market requirements by combining the benefits of UV LED and water-based inkjet. It has low-energy, low temperature drying compared to traditional water-based print systems.

It provides adhesion to a wide range of media without the need for a pre-coat primer or optimiser.

Prints have a thin film, that is scratch-resistant and does not require a top-coat. In addition, they are low-odour and safety compliant. The technology offers excellent jetting stability through reduced nozzle blocking due to low temperature drying.

“This machine is 1.6m wide and is our first machine in the 1600 market. It is a four colour process with UV and water-based inks. We’re going for the instant cure and environmentally safe side of it as well. Water-based uses minimal amounts of power consumption, especially with the LED lamp to cure it,” Fisher said.

“It takes up to 400gsm of stock, roll-to-roll, and can be combined with a cutter to print and cut applications like stickers.”

In addition, the new Revoria Press SC285S and Revoria Press EC2100S, which were shown at China Print last week, made their Australian debut at PacPrint as well.

With the help of Super EA-Eco toner used in high-end models, both the Revoria Press SC285S and Revoria Press EC2100S enable users to experience high-quality CMYK printing and achieve shiny metallic colour and gloss.

Their compact high-quality LED print head can provide high-resolution output of up to 2,400dpi x 2,400 dpi to achieve high-definition printing with clear lines and images.

The Revoria Press EC2100S is compatible with a variety of papers, has post-processing functions, and is easy to operate. It features an automatic optimisation function using Revoria Flow, of neon pink toner to achieve a wider colour gamut.

It allows for high-speed printing of uncoated paper (52gsm to 400 gsm) and coated paper (72gsm to 400 gsm). Its A4 productivity is up to 100 pages/min, while its A3 print productivity is as high as 55 pages/min.

The Revoria Press SC285S supports a wide range of paper types and sizes, including various paper sizes as small as 90mm ×146 mm and as large as 330mm × 660 mm, and supports optional long paper printing (single-sided) up to 330mm × 1,300 mm.

From 52gsm thin paper to 400gsm thick paper, it can flexibly handle various gram weight media. In addition to printing a variety of exquisite materials, the machine also has various common business office functions such as copying and scanning.

Its production efficiency of A4 is up to 85 pages/min, while the production efficiency of A3 printing is as high as 47 pages/min.

Other products on show include: the new Revoria Press PC1120 + Plockmatic Booklet Maker, the Acuity Prime Hybrid, and Revoria XMF PressReady integrated print workflow.

Watch Justin Kirkland from Fujifilm showcase the Acuity Triton with Aquafuze water-based ink technology at FESPA Global Print Expo in Berlin

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter