A decade ago Fujifilm was faced with a tough decision. At the time the firm was seen to be lagging behind its rivals in terms of workflow development and it realised that if it wanted to change that perception it had choices to make. It could continue to rewrite its existing software and risk losing further ground, or it could make a bold statement and completely rebuild its workflow from scratch.

The company plumped for the latter option launching Fujifilm XMF Workflow in 2007. In doing so it became the first to market with an Adobe PDF Print Engine-based workflow that was fully JDF compatible.

This ‘reset point’, as Franca Balsamo, Product Manager – Plates CTP and Workflow, Graphic Systems, Fujifilm Australia refers to it, has over the last seven or so years helped Fujifilm to differentiate its workflow product from rival software, leaving many other products in its wake.

“Most products on the market evolved from using other technologies and were then modified to take on board Adobe PDF Print Engine and JDF,” explains Balsamo. “XMF is the only system out there that was specifically designed to use these technologies.”

The advantages of building Adobe PDF Print Engine and full JDF capability into the workflow’s architecture has become abundantly clear with every new incarnation of the product, with each new version pushing the boundaries of what was possible at the time.

Version 2.0 included a new online job submission module, Version 3.0 was bolstered by web-offset and variable data capabilities, Version 4.0 featured significant advances in imposition capabilities and Version 5.0 included new job versioning tools, further integration with MIS systems, enhancements to its 3D proofing module and further speed improvements to job rendering times.

So when Fujifilm announced last year that it was due to unveil XMF v5.5 in September, industry experts excitedly started to speculate as to what technological enhancements the latest incarnation would bring. And when it hit the market they weren’t disappointed.

Architecture

In addition to a number of new variable data and productivity enhancing features, which are 'designed to optimise high speed print production’ on the company’s Jet Press 720 and 540W digital inkjet presses as well as optimising more traditional CTP plate production, XMF Workflow v5.5 became one of the first systems on the market to use Adobe’s new scalability framework Mercury RIP Architecture.

Upgrading the ‘guts of the workflow’, which was made possible thanks to the existing Adobe/JDF platform, meant that Fujifilm could quickly and seamlessly add in the new Mercury Architecture to drive data-rich, high-volume digital print production, says Balsamo. “Mercury’s parallel processing architecture features distributed multi-tier caching and dynamic load balancing to take full advantage of available hardware,” she adds.

Balsamo explains that some of the fundamental enhancements included in XMF v5.5 are applicable to any customerm using the workflow, but the latest version is geared towards addressing the high demands placed on workflow systems by modern digital presses.

Automation

One of the ways in which XMF v5.5 allows users to increase their productivity and competitiveness is through a high degree of automation, says Balsamo. “We’ve tried to focus on making sure it’s got all of the capabilities printers

Fujifilm built a new digital workflow solution XMF, and has now released Version 5.5, which amongst other developments can drive data rich high volume digital applications would expect from a workflow, but because printers need to get on with printing as quickly and easily as possible there’s been a lot of focus on improving automation in the workflow and I think we’ve got to the point where it’s pretty streamlined now.”

To underline these improvements she highlights the workflow’s improved 3D proofing capabilities. The module was embedded in previous versions of XMF, but previously the user would have to go into the system, generate a 3D print and then send it to the client to review.

Within XMF v5.5 this is now processed automatically, which saves time and increases efficiencies.

“So up front if a printer knows that he’s going to have to send some 3D proofs to a client he can input this into the system and when there is enough information available to generate a proof it will do that and email it directly to the client,” says Balsamo. “Improvements such as this have come about from us talking to the customer to find out what they want from their workflow and they just want more automation – they need to manage the system, but they want to get away from an operator having to do every single job.”

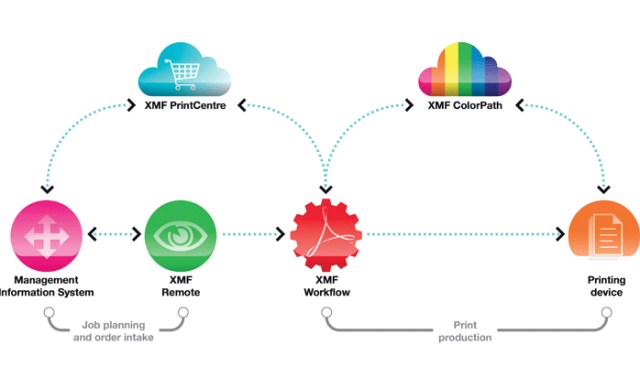

If further proof were needed Balsamo highlights the optional XMF Remote v9.5, which launched in December featuring a new user interface based on HTML5. Remote allows clients to directly submit and approve jobs for printing, either via a computer or a tablet device – once approved in XMF Remote by the client jobs are automatically sent to XMF Workflow to be printed.

“Most companies who invest in XMF Workflow take XMF Remote as well, as it opens up the product to their customers who can interact with their own workflow directly rather than sending over a lot of suggestions and instructions to the printer who then has to deal with all that information himself. This way the client gets to do a bit of the work themselves – not that you’d want to tell them that,” says Balsamo.

Technology upgrades

Further technology enhancements introduced in XMF v5.5 include support for PDF/VT and PPML variable data formats, plus a new VDP database ‘to sustain the high data processing volumes associated with VDP in order to maximise the productivity typically required by fastmoving digital print environments,’ according to Fujifilm.

The company has also recently attained CIP4 certification for XMF v5.5, which guarantees full integration between an MIS system and the workflow. “We’ve been supporting MIS for years, but we’d never focused on going through the certification process previously. However, because we were going through such a major revision we decided to take the opportunity to integrate it into the release,” explains Balsamo.

In addition improvements have been made to the workflow to support XMF ColorPath – the cloud-based colour management system, which has been designed to help printers calibrate and maintain compliance to printing standards.

The alternatives

AGFA APOGEE 8.0

Launched in 2012 the latest generation of Agfa’s prepress workflow includes a cloud-based web-to-print solution called Agfa StoreFront. It also includes Agfa WebApproval for file and soft proof retrieval and Apogee StreamProof for the annotation of fast, high resolution soft proofs. Price on application

Contact Agfa

HEIDELBERG PRINECT PREPRESS MANAGER

Heidelberg’s integrated CIP4 workflow provides digital links between pre-media, press, finishing, MIS and web-to-print functions. The company is expected to launch a full upgrade to Prinect this year, with rumoured developments including improved MIS information to help with costings.

Price on application

Contact Heidelberg

KODAK PRINERGY 6.0

Kodak unveiled its latest version of Prinergy last year, with the most significant new feature being a streamlined user interface called Workspace, which consists of three modules: Manage, Plan and Track. Prinergy is suitable for all sizes of commercial and publication printers as well as trade shops, according to Kodak.

Price on application

Contact Kodak

SCREEN TRUEFLOW

This fully JDF-compliant PDF workflow system boasts a userfriendly interface, with job files presented in an easy to understand, graphical form. According to Screen the workflow “minimises the variations in output from different devices by tailoring the data for the specific output device, whether requiring embedded fonts or adding trapped data.”

Price on application

Contact Screen

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter