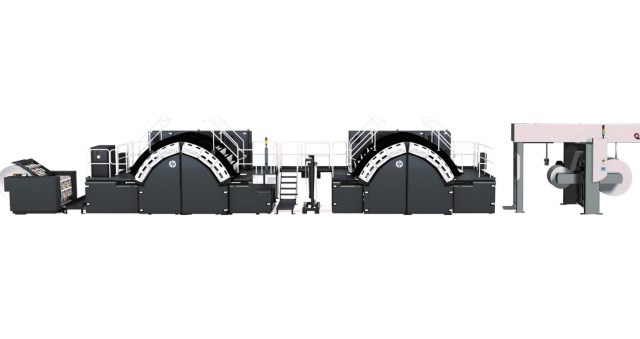

It comes with auto plate changing as standard, is designed for flexible run lengths, and has a compact height of just 2.2 metres.

Goss says the new press has come about due to changing habits of readers and emerging opportunities for printers, The new Goss Magnum Compact press system has a range of design features packaged to deliver fast makereadies, simplified operation and run-length flexibility.

The new design retains features of the Goss Community Magnum platform – which Goss says is the world’s best-selling single-width press platform – while introducing automatic plate loading and compact design to this market sector for the first time.

The company says the inclusion of automatic plate changing as standard is a crucial factor in delivering new capabilities. Enabling plates for the next product or edition to be loaded while the press is running, the full sequence of old plate removal / new plate loading requires less than 30 seconds, producing a dramatic impact on crew requirements, makeready waste and press uptime. Additionally the removed plates can be reused – making this technology suited for repeat small-batch production of books and other publications.

Multi-shaftless press drives are similarly standard on every model, with the result that each cylinder level and inker module is driven totally independently, as is the infeed roller, providing maximum flexibility and control over changeover waste. This control can be further enhanced with the addition of optional Goss DigiRail digital inking.

According to Eric Bell, Goss International marketing director, this combination of automation technologies makes the Magnum Compact press ideal for producing run lengths from as low as 500 copies through to 250,000 or more.

He says, “Today’s cost pressures on printed media mean that printers of every size and variety need to streamline production, reduce overheads, and keep their presses running round-the-clock. This press system is another example of Goss using its decades of engineering and technological expertise to bring the benefits of automation and large-scale production efficiencies to smaller operations. This latest innovation will deliver more flexibility and opportunity for printers of newspapers, as well as books and specialised or niche publications.”

As well as the widely-acknowledged print quality benefits of compact towers, the short height (2.2m), single-level design of the Magnum Compact press also provides clear operational benefits, enabling prepress, press and mailroom to be operated seamlessly. Maintenance is also simplified – the opening of the inker units allows simple, single-level access to blankets, rubber rollers and ink ducts for cleaning and setting.

Goss says that in reducing makeready time by as much as 90 per cent, the automation of the Magnum Compact enables printers and publishers to reach into new markets and new applications as short run lengths and low pagination can be produced cost-effectively. Folders accommodating up to 16 webs enable smart production configurations, while quarter folder and double parallel options add format flexibility for books, semi-commercial magazines, direct mail and academic literature. Heatset and UV options can also offer added-value.

Bell says, “Tackling the main sources of cost in printing, the Magnum Compact design incorporates features for reducing overheads – including crew sizes – and materials consumption into a press design that facilitates a wider application range. What’s more, with greater substrate flexibility and the use of standard inks and consumables, the Magnum Compact press even presents a compelling alternative to inkjet presses for a number of applications and business models.”

The new Magnum Compact press is expected to have worldwide appeal. A full four-color inker module with automated plate changing is being debuted at China Print in Beijing this week.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter