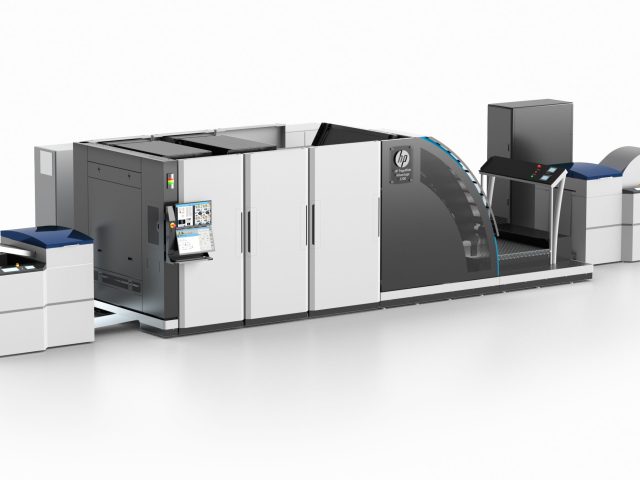

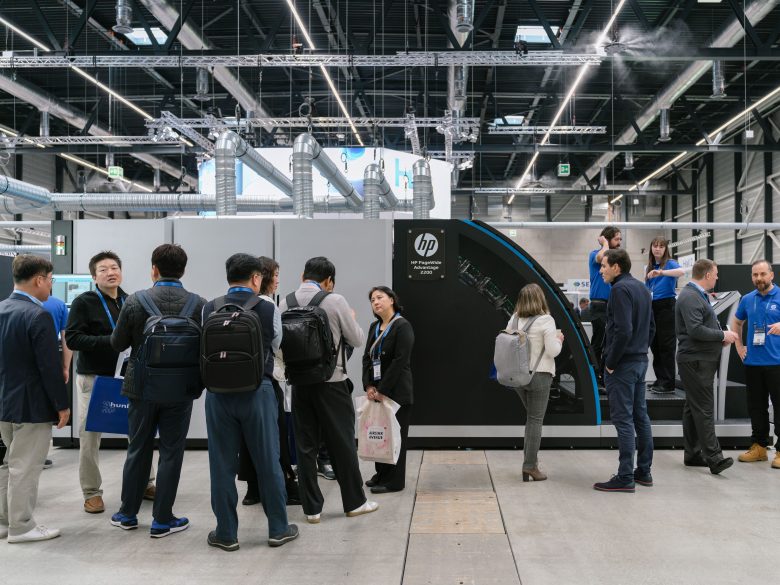

HP took to Hunkeler Innovationdays to introduce a smaller, cost-effective new configuration for its HP PageWide Advantage 2200 web inkjet press. The new configuration features a single-zone drying system and a passive web cooling module, allowing customers to print mono and full colour jobs efficiently across a wide range of uncoated and coated applications.

Designed for PSPs whose primary print offering includes uncoated media, the new configuration offers the opportunity to expand into high-value commercial print applications on offset coated media.

While optimising total cost of print, the press has the capability of printing colour jobs up to 244m/min with PageWide’s powerful new Performance Economy Color print mode. Built on a modular platform, the new configuration can be upgraded with additional drying and web cooling, to enable PSPs to scale capabilities as their business grows.

“Our customers value the flexibility of the modular HP PageWide Advantage 2200. The digital press enables PSPs to offer print solutions that meet customer needs and growth aspirations for their business,” HP PageWide Industrial vice-president and general manager Barbara McManus said.

“With the new single-zone dryer configuration with passive web cooling, more businesses than ever can access a unified platform that supports diverse printing applications and differentiate themselves from competitors with high value jobs, all in one easy to upgrade press.”

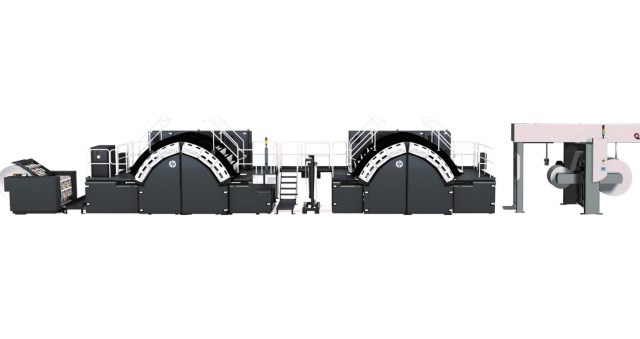

HP also demonstrated its fastest integrated book production solution at the show, printed with both HP Indigo Liquid Electrophotography (LEP) and HP PageWide Thermal Inkjet (TIJ) printing technologies.

The fully integrated book production line was orchestrated by the HP Intelligent Automation Platform, PrintOS. Leveraging HP Site Flow, nearline intelligent automation with HP PageWide Smart Workcell Controller and partner technology from Hunkeler, Harris & Bruno, Muller Martini, IDEAL, Movigo and Spencer Metrics, the solution produced more than 750 books live but can produce up to 2,000 books per hour.

HP Indigo also introduced the next generation of consumable supplies designed to enhance print sustainability and boost productivity. The key innovations include the CMYK+ with new advancements such as a higher ink solid concentration, the Printing Imaging Plate (PIP+) with a new formulation in two key layers, and the Regenerated Imaging Oil (RIO), in-press recycling system for the ink carrier.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter