A sure-fire way for printers to step up productivity, reduce waste and improve conditions for staff on the shop floor is simply installing a humidifier, says Gert Diepold, managing director of Lifhart. Diepold says Australian printers of all shapes and sizes stand to gain by installing the technology to make static build-up, web breaks and paper curl a thing of the past.

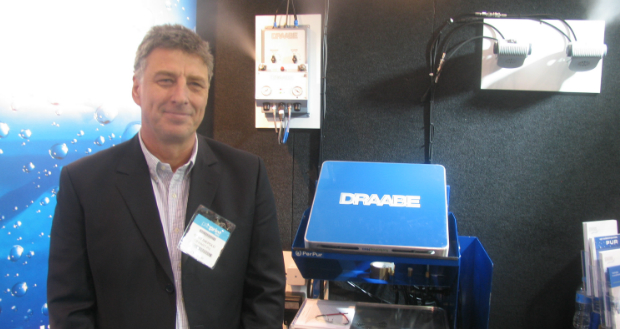

For the past 25 years, toolbox in hand, Diepold has been called out to help printers fix humidity levels in factories, workshops and garages, and to repair surface damage on cylinders in machines big and small, old and new. He has exhibited at the last three PacPrint expos in Australia, and says that while many Aussie printers are interested in chatting about their humidity issues, and are even keeping daily tabs on their levels, some are reluctant to take the next step and bring it under control. He tells Australian Printer, “One company I have visited take readings of their air humidity twice a day in the factory. They link their humidity levels to whether production is down or up – so they know they have problems, but haven’t committed to fixing them. “Then there are the more proactive companies that have put a new machine in and are keen to go ahead and humidify the print room straight away, because they want the machine to perform at its optimum by ensuring the ambient conditions are right. “The Draabe products I sell for humidification are high profile, but affordable. At drupa they hang from the ceiling in halls one and two for big players like Heidelberg and Hewlett Packard – because they want their presses to perform at their best. “With the amount of wasted ink and paper they can save you, over time the humidifiers do pay for themselves, and if you’re going to invest thousands or even millions of dollars into new equipment, the cost of installing these for the best performance is relatively small.” Diepold adds that taking charge of humidity can be especially important for certain sensitive presses. He says, “A lot of smaller printers have problems with air humidification with their digital presses. For instance, the HP Indigo press doesn’t like it when it is too dry. There’s actually an internal humidity metre on the press, and if it goes too low the press will shut down.” There are further benefits for keeping humans happy too – moderate humidity levels mean less chance of a sore throat, and in summer evaporative cooling makes for a more comfortable workplace.

Coming up to Lifhart’s 25th anniversary, Diepold has carried out hundreds of repairs on printing machines around the country. He says, “Big newspaper presses, little machines, it doesn’t matter. My customers range from Australia’s biggest printers, to floor printers who work from a garage. “When I started my repairs business in 1989 I was the only one doing it in the country, and some of my customers have stayed with me over the 25 years. I have also helped out press manufacturers like Heidelberg and manroland, and I have worked for insurance companies looking at damage claims on presses. “There is a bit of scope with that business, but it has declined recently since a lot of units have been knocked out of the game through companies which have collapsed. So there are less presses out there, but when they do break it’s a specialist job to fix them. “We’re still going – we have survived tough times in the past, and hopefully there is still enough work out there to accommodate us. There are presses around that may need fixing, and every printer can benefit from installing a humidification system – so we’ll be around to take care of that for our customers.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter