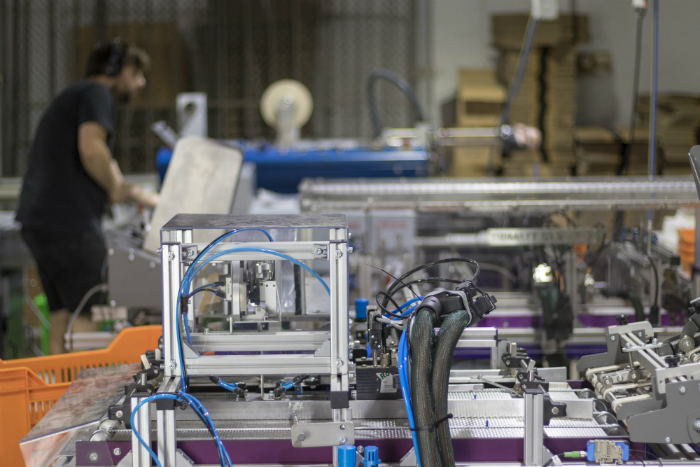

Melbourne based Implant Media is investing in its third custom built finishing set from Trimatt, a new gluing machine.

Shiran De Soysa, owner of Implant says, “The new gluer replaces some semi-automated glue machines that we had – it 45 minutes it can do the work the previous devices could do in a day, with one less operator.

“Now that we can glue larger packs faster, it lets us think about creating new larger pack shapes at a more economical price point. We do all our die-cutting in-house, and are looking at offering new short-run USB gatefold and packing, also packaging with slits that can hold credit card sized objects.

“We wanted the new machine for efficiency. We saw how much time the previous machine was saving in actual gluing time, which also meant that jobs were ready quicker. This helps with scheduling as we don’t need to plan as much for when pack print jobs needed to be printed to meet deadlines. Now we can print/die-cut/glue all the components ready to be packed with the CD, DVDs and USBs that we produce in a just in time scenario.

“We needed to automate the glueing of some of our larger disc and USB packaging that we carry. We already had a machine that Trimatt had built for us that could handle standard size packaging, which is smaller but has more complex folds and glue lines. We knew that it would be easy for them to come up with a solution for the larger packs.

“We had a need for a machine that had a quick makeready as our run lengths can be quite small. That is why we went for the custom machine as we don't really have a need to glue anything other than the packs we carry, so it made more sense to a have a dedicated machine that can do a few things rather than a complicated machine (with longer setup times) that can do everything.

[Related: Kwik Kopy invests in Mamo]

“Trimatt pretty much built everything but the feeder and digital glue system from scratch, I think even the frame was made in-house. Because what we need is so particular, with quick changeovers and packs with similar dimensions but varying glue patterns, it was the only way to do it.

“We have another custom glue machine that can glue our 4 panel CD/DVD/USB Gatefolds and CD/DVD/USB digicases as well as card sleeves. We then have another machine that can glue the plastic CD/DVD trays onto 4 and 6-panel digicases.

“Trimatt understand what we are trying to do and what we need from a device. We could have bought machines off the shelf but as our work is so particular and run sizes can be so short we really need to have something custom made so we weren't spending all our time and money setting the machines up. Trimatt understood this and worked with us to build machines that fitted our brief perfectly.

“There is a big sign on the front of our building that says "We Print Stuff" but at our heart, we are a print business that specialises in work for bands and the music industry. We still do business cards, stickers, and general print but 90 per cent of our work is CDs and DVDs. We do a bit of corporate work as well, mainly USBs and the packaging that goes with it and associated print. Many of the other suppliers in Australia for USBs are promotional companies and they don't have much print equipment. We can make all the packaging in-house so we can offer products that you cannot get from any other printer in Australia.

“We started Implant in 1999 in Brunswick East, Melbourne and have been there ever since. It is owned by myself and my business partner.

“We have usually have a team of 12, eight full-time staff and then four to six casuals that work depending on how much work we have on.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter