Perez says that although the US part of the company is still in bankruptcy protection Kodak has a strong future, and its customers and suppliers are continuing to work with Kodak, highlighting customers such as Toppan in Japan which has just ordered its fourth Prosper.

Kodak’s live presentation theatre, the K-Zone, features discussions with industry experts, product representatives, customers and strategic partners in more than 60 live sessions.

On its stand, the company unveiled enhancements for its Nexpress, including a new turbo mode, a 914mm-long sheet option and a new calibration system for software. The turbo mode supports speeds up to 166ppm A4 on the Nexpress SX3900 while printing two-up on A3+ sheets or on finished size A4/letter-size sheets. The Nexpress prints on nearly 800 supported substrates out of the box, and Kodak says operators can add a virtually limitless number of custom substrates. All Nexpress platforms come equipped with Print Genius, a suite of productivity and quality control tools. The new ICS version 3 software offers 20 percent faster processing time, smoother flat fields and extended parts life.

Available immediately for black and white printing, the new Digimaster HD platform includes three models: the HD125, HD150 and HD300, with respective rated speeds of 125 ipm, 150 ipm and 300 ipm. Features include a smaller toner particle size and improvements in the imaging components and software with a 25 per cent higher yield per toner bottle; a new fusing system design; runs at full rated speed across a wide range of substrates; completes complex finishing tasks in line, including perfect-bound books and saddle-stitched documents in a variety of sizes; a choice of engine performance with the capability to upgrade to 300 ipm speed and modular finishing components.

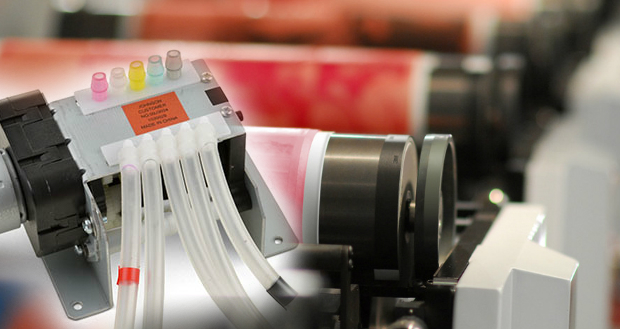

The company has released the new Kodak Prosper 6000XL a four colour press that runs at 304mpm with monthly print volumes of up to 160 million A4 pages. The new Kodak Prosper S30 Imprinting System offers what Kodak calls the highest speed in the industry at 3,000 fpm, delivering 600 x 200 dpi output with application for hybrid printing applications such as direct mail, inserts, gaming, advertising, package labelling, and more.

For packaging, Kodak has spotlighted flexographic printing solutions, offset plates, workflow systems, brand protection solutions and digital printing presses. The new Kodak Flexcel Direct System, with equipment, sleeves and printed material on display, demonstrates how high-power laser engraving produces press-ready elastomer sleeves. The imager and consumables are designed to work as an optimised solution. Kodak says its Flexcel NX Plates offer printers a wider colour gamut, higher densities and greater print stability than traditional digital flexo plates.

The company says its Trillian SP Plates deliver a long unbaked run length capability, including UV and strong chemical resistance, and fast processing speeds. The Kodak Sonora XP Plates offer high-quality thermal imaging and the complete elimination of plate processing, according to Kodak, which adds that the plates can help increase productivity, simplify operations and remove costs by reducing the number of steps required for platemaking.

Kodak also highlighted the fact that, at drupa, it will work with more than 40 partners. Powered by Kodak Stream Inkjet Technology, the The Timson T-Press on display at Kolbus’s stand in will include the T-Fold finishing system producing printed and folded signatures running in line with a Kolbus Binding System to demonstrate the short-run capabilities of both systems. Komori will print jobs on its H-UV printing presses using the Kodak Sword UltraThermal Plate. Colour proofs from the Kodak Matchprint Inkjet Proofing System and ink key settings will be generated by the Kodak Prinergy Workflow system. In another application, Illies Graphik will print on-site the German trade magazine Deutscher Drucker on a Ryobi 928 Press using Trillian SP Plates. As the supplier agreement between Collins Ink and Kodak concluded, Kodak assured its Versamark customers that they could continue to order Kodak inks directly from Kodak with no change or disruption in service.

Perez took a trip down memory lane. He said in 2004 Kodak announced entering commercial print market, said print would be hybrid digital offset environment. He highlighted Kodak’s leadership in materials science, digital imaging, and deposition technologies, and as commercial printing at intersection of these three sciences Kodak is, according to Perez, well placed. In 2008 Kodak showed wide portfolio, and introduced two breakthrough technologies; the Prosper press based on Stream technology, and Flexcel NX for high quality packaging for lower cost.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter