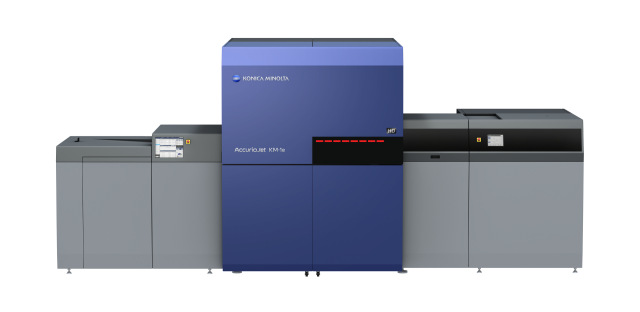

Above: The new top of the line AccurioJet 60000 which will be positioned above the KM-1 and KM-1e machines

Konica Minolta has unveiled a new top of the line AccurioJet 60000 which will be positioned above the KM-1 and KM-1e machines.

Speaking to global journalists at the pre-Drupa global press conference at Messe Düsseldorf in Germany, Konica Minolta head of marketing for Konica Minolta Business Systems Europe, Olaf Lorenz, confirmed Konica Minolta will show the top-of-the-line model AccurioJet 60000 for the first time at Drupa from May 28.

“The AccurioJet 60000 further enhances the quality and functionality of the AccurioJet KM-1 and KM-1e, which have been used around the world since the release in 2016 for various printing applications such as various printing papers and PVC plastics,” Lorenz said.

“The AccurioJet 60000 maximizes throughput with high productivity of 6,000 sheets/hour and improves automation and labour-saving. Using HS-UV (High-definition, Single-pass UV) ink, it maintains high image quality and gloss reproducibility that approaches offset printing, while a high level of colour stability is achieved with easy operation.”

Lorenz also provided an overview of the major products to be shown on the 2500 square metre Konica Minolta stand from 28 May to 7 June under the theme ‘See the Potential in the Future of Print’.

With a particular focus on labels, packaging and embellishment, Konica Minolta and MGI will demonstrate the most efficient use of digital print automation and end-to-end production workflows, as well as world-class software solutions.

Above: The new AccurioJet 60000 will be the new top of the line machine, but the KM-1e platform will be retained by Konica Minolta

For the first time, Konica Minolta will also provide a live demonstration at Drupa of the AlphaJET integrated system incorporating printing and finishing equipment.

“In order to create a sense of luxury and meet the diverse needs of customers, embellish printing is performed using spot varnish to create a relief effect, foil stamping, etc. for packaging. Since many companies and departments are involved to handle plate creation and each process, redundant printing and time consumption are issues in the industry.

“AlphaJET, provided by Konica Minolta together with its France-based partner MGI Digital Technology, performs all processes necessary for package printing, from inkjet printing to embellish printing and post-processing, all in one step. It significantly shortens process time, reduces installation floor space and waste, and provides a clean working environment,” Lorenz said.

“Under the main message of “See the Potential in the Future of Print”, Konica Minolta will propose a future vision for printing companies by making full use of its unique technology and know-how, which the Company has cultivated over many years of working closely with partners committed to printing.

“Konica Minolta’s top priority is to automate and provide assistance technologies for the printing process and maximize throughput. By reducing the routine work time required to prepare for printing, productivity of the entire printing process will be improved, and operator stress is reduced. At the same time, by focusing on the professional quality that printing companies require, Konica Minolta increases customer satisfaction and trust in the printing company.

“In addition, by providing a variety of support functions that enable even less skilled and inexperienced operators to work comfortably and achieve high performance, Konica Minolta contributes to improving the working environment of printing companies, reducing environmental impact, and improving business continuity.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter