The Lithographic Institute of Australia (LIA) is giving its NSW members insight into 3D printing, having hosted an event looking at the latest developments in the sector at a high level evening presentation in Sydney.

The seminar included talks from vendors Océ, Fuji Xerox, Konica Minolta; industry identity, Andy McCourt and high profile end user, Bruce Scott of Composite Images.

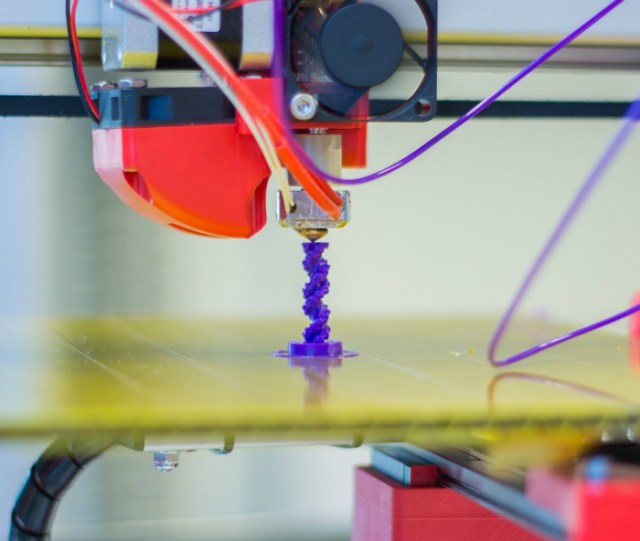

Matthew Hunter, national manger of 3D Printing, Konica Minolta, and Paul Budgen, national portfolio manager for wide format and 3D at Fuji Xerox gave overviews of the different forms of 3D printing technology available, along with their applications for different products and industries.

Giving an update Andy McCourt says, “Right now, the majority of revenue for 3D printing is going to end to market users, who want to make their own items. At the moment, it is not hugely profitable for printers.

“We are still looking for a business model, for where it falls into graphic arts and the visual industry. Maybe there will come a time when printers will need to have new skills and new disciplines. At present printers may be able to incorporate 3D within signage, display and other sectors.”

[Related: LIA call out for skills survey]

Gary Muratore, product manager, Graphic Arts at Océ took the opportunity to talk about Touchstone, the company’s new software for elevated printing, describing it as 2.5 printing. The solution, which launches in Australia in around two weeks, is designed to allow Océ flatbed printer to easily print multiple layers, resulting in effects that mimic different textures, embossing, metallic accents and raised lettering.

Muratore says, “This is a different application of additive printing, but it is more of how we see it fitting in with graphic arts. It can be printed to about 1mm high and it gives texture, it can be used for tactile printing, for example braille and raised letters.

“Previously, printing in layers was labour intensive, you had to think about how many layers and a flatbed had to be able to handle pixels. It was also inefficient, hit or miss and you needed a certain expertise. It could not be visualised beforehand.

“With this software, you do not need any specialised training, you do not need any expertise and you can use existing equipment. You can see cliffs and valleys in advance, and you are able to have colour and build up in each layer, which you could not before. In the past, the colour went after.

“Quality is no longer enough, print shops need a differentiating factor. In terms of market demand, customers are willing to pay more for embellishment.”

[Related: Composite prints 3D rugby giants]

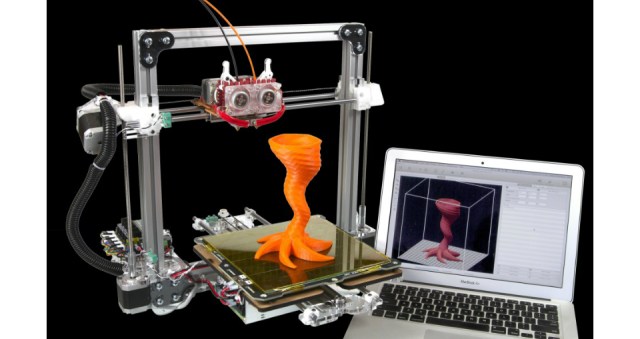

Bruce Scott, CEO of large format printer Composite Images, also spoke of his experience with 3D printing. Scott purchased a Massivit 1800 two years ago at the drupa trade show.

He says, “I deal with signage, point of sale and display.

“What we are able to do with the Massivit is all about point of sale. It fits in with what we do. We are starting to get more work with it.

“What printers are about is creating images, we are the best at making images. This is another form of that and it is a growing market.”

Last year Composite used the Massivit to produce 14 larger than life models for the 2017 Rugby League World Cup, which travelled with the competition.

Around 40 printers were at the event, held at Carnavon Golf Club, and also enjoyed networking and a meal as part of the evening.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter