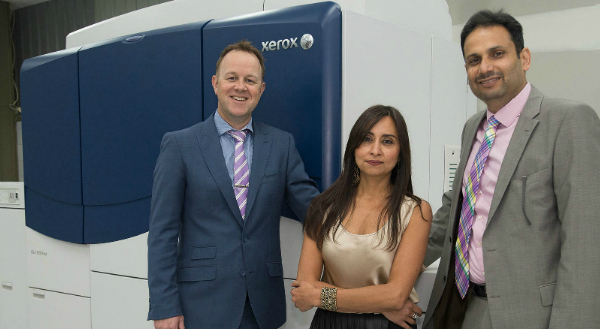

OCA is doubling its digital capacity to meet demand for its upcoming trade services launch as fresh kit progressively moves into its new Melbourne plant.

The company has just installed a Fuji Xerox iGen 150 and Color 1000 Press into the former Geon site, duplicating the existing digital stable of its Print Bound subsidiary, in addition to a Nuvera 144 EA.

OCA chief executive Naresh Gulati says the investment is in response to interest from printers looking into signing up for his end-to-end trade services.

“We have chosen these two printers to meet the needs of future trade partners in the short run digital market,” he says.

“It will future-proof our production to meet anticipated trade work, and allow for growth as printers embrace a collaborative model.”

[Related: Kitted up]

Gulati says the printers will be used for both trade and in-house work, particularly for variable data printing, short run commercial, and direct mail.

“We have tested these machines with our software and ordering systems to ensure seamless processing and no bottlenecks for our future trade partners,” he says.

He says he chose to double up on Fuji Xerox kit because the existing machines were working well and his company has a strong partnership with the manufacturer.

OCA is also installing a top range Heidelberg CTP system to be paired with the Heidelberg XL 106 six colour offset press going into the factory later this year, along with the existing two offset machines.

The system includes automated Prinect Pre-Press Manager workflow, the Suprasetter 106 with multi-cassette loader, Fujifilm ZAC Processor, and Brillia LH-PLE thermal plates, which are designed for long run UV printing and don’t require baking.

Gulati says until now his company outsourced its CTP and the investment is an example of how printers can use trade services like his to build a market before they are read to buy costly equipment.

He says as Print Bound has grown from having only one offset press, a Heidelberg Speedmaster 102 12-colour press, to three with a Heidelberg CD 74 five colour and the incoming XL 106, insourcing prepress is now justified.

“When I bought Print Bound in March it only had one machine, and now is about to have three there is the business to support CTP investment,” he says.

“Printers should use trade partners until they have built a business that, after financial analysis, is sustainable enough to pay off the equipment quickly. It is a classic strategy that works in these unstable times.

“We expect to see a return on investment in less than two years and owning it will give us more flexibility and ability to offer more to the industry.”

[Related: OCA announces trade services]

Gulati says a collaborative model can save the industry from the ‘massacres’ it is enduring, with the latest casualties On Demand and Sumo Visual being in his own city of Melbourne.

“These recent collapses are tragic and my heart goes out to all the workers who have lost their jobs and businessmen like Bruce Peddelsden whose hard work has gone down the drain,” he says.

“However, tragedies like these will continue to happen until the industry cooperates to bring costs down. Corrective action must be taken now.

“We have to work with each other to stop dropping prices in a race to the bottom, and stop the dangerous reliance on a few big clients that could leave at any time.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter