“Manufacturers are now launching processless and chemistry-free plates. We’ve built our CTP [systems] with speed upgrade ability so they can adjust to the plate,” he said.

At present, manufacturers are concentrating most of their development efforts on devices that accept processless thermal plates, but in the future this is likely to change.

Agfa, Fuji and Kodak are all set to release, or have already released, new plates and some of the older devices can’t accept these new products, said Elliott. It might be a case of needing extra laser power or debris-extraction capabilities. However, most processless and chemistry-free plates can still be imaged by the current breeds of platesetter.

There are three components to a CTP system: the digital controller or computer, laser imaging optics and imaging surface. However, the buyer’s choice of plate type will usually determine what sort of platesetter they install. When investing in a new platesetter, the buyer also need to factor in additional expenses, such as workflow software.

Buyers should consider the wealth of workflow features that can be bundled with a platesetter, such as closed-loop colour and image control.

Many of the early platesetters, installed in the late 1990s, are now coming to the end of their effective lifespan so there are many buyers out there who will be looking for new kit to replace these. The UK’s platesetter market is a good one to be in, explains Brian Filler, Screen UK managing director. It is very much a replacement market, but a buoyant one nonetheless. Printers are installing faster presses and therefore need a platesetter that can keep up, so they are installing more productive machines, or even additional ones.

When choosing a new platesetter, buyers must decide what plate formats they will be using and the quantities and size of output they want to achieve, as well as what workflow will best suit their production systems.

WHAT’S NEW IN… PLATESETTERS: FLEXO, NEWSPAPER AND VLF

• Heidelberg launched its Suprasetter 145 and 162 platesetters aimed at customers that bought its new Speedmaster XL 145 and XL 162 presses. The systems can image a maximum of 35 plates per hour at 2,540 or 2,400dpi. A third CTP , the 190 imaging up to 25 plates per hour, was also unveiled for even larger plate sizes

• Screen unveiled at drupa what it claims is the world’s largest platesetter, the PlateRite Ultima 48000. The unit can image plates for 96pp web presses and can output plates up to 2,900×1,350mm in size

• Kodak has launched its Magnus XLF 80 Quantum platesetter. The superwide-format CTP is an extension of the Kodak Magnus VLF Platesetter line, expanded for larger plates

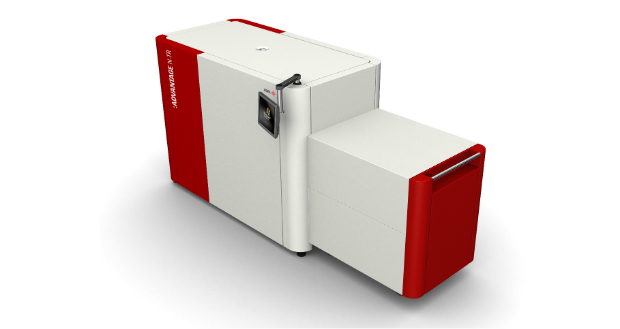

• Agfa unveiled a new range of B1 and VLF thermal platesetters at Drupa. The Avalon N, B1 N8, VLF N16 and N36 will be joined later in the year by the N40 and N48. Both are suitable for the latest 80pp and 96pp web presses with a speed range from eight to 50 plates per hour

Read the original article at www.printweek.com.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter