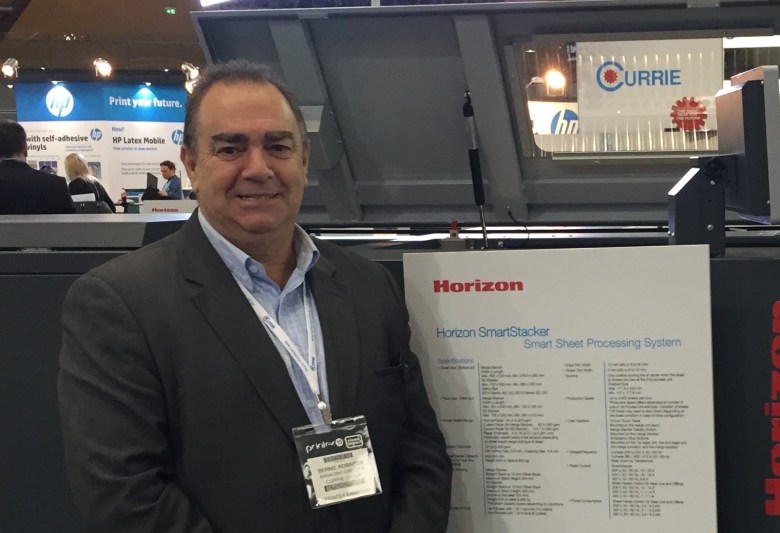

This article was first published in the March 2021 issue of Australian Printer, by Currie Group managing director Bernie Robinson

Horizon is a leading global provider of high-quality finishing solutions for the graphic arts and print-on-demand markets.

The product line includes collators, booklet makers, perfect binders, folders, paper cutters, and a growing family of in-line and near-line finishing products that are custom-tailored for the print-on-demand marketplace.

Horizon’s focus is to minimise touch points on the finishing side with products transitioning to an offset or digital web or sheet feed model. It includes features such as mobile tracker carriers for paper movement directly into a press. It then goes from the offset machine to either a folder or perfect binder, then to a three knife trimmer unit before being moved directly onto the mobile tracker carrier to the despatch area for a courier to pick up.

But machines aren’t the only technologies that need to be depended on. Software such as iCE LiNK, which is a cloud-based workflow management system can manage multiple finishing devices and optimise production to create a new work environment and a higher level of efficiency.

The iCE product series is a new product line-up which is designed to provide added value to our customers, enable a more integrated operation, and advanced automation to provide increased efficiency and productivity.

When it comes to challenges, one of the problems that printers face when folding digital print is the cracking of the spines of books.

The Horizon CRF-362 impact creaser and folder with two-fold knives is designed to handle heavier sheets in one pass without cracking. A workhorse for commercial printers, it’s suitable for creasing covers, restaurant menus, shop cards, invitations and laminated sheets.

It can also be used to prepare high quality perfect bound book covers with spine, hinge and flap creases properly produced by selecting up or down creasing. It’s a very popular item that doubles as a perforator. We sell two to three a month. It’s also pretty quick, up to three thousand sheets per hour.

Another popular investment for printers addressing the book market is the Horizon BQ-280PUR binder.

PUR is polyurethane adhesive that has become popular due to its superior binding strength and lay-flat qualities when a book is pressed open. It’s ideal for educational booklets, cookbooks, and photo books. Unaffected by ink, PUR has almost entirely displaced the alternative hot-melt EVA glue due to its lower application temperature and better environmental outcomes in terms of recycling.

The BQ-280 is a single clamp perfect binder that is a favourite with commercial printers. It can produce three hundred and fifty books per hour. We sell it with Kleibert glue and recommend a warming unit so that there are two cartridges ready to be used at any time. We also have the larger machine, the Horizon BQ-500 with four clamps that can turn out eight hundred books an hour.

The Horizon SmartSlitter is versatile sheet processing system that can slit, perforate, and score all in one pass. Ideal for coupons, tickets and business reply cards the system can deliver multiple up greeting cards with or without creasing. Accordion fold applications or perfect bound books with up and down creasing can also be performed in one pass. It’s becoming more common for printers to output standard size business cards 21-up on a sheet. With the SmartSlitter print registration marks adjust for image shift from sheet to sheet.

It’s a very easy machine to operate, even for non-skilled operators. The colour touch screen has a simple user interface that lets a job be set-up using a barcode. There are a number of features that Horizon has introduced, including the ability to run partial perforations both across and along the sheet to create tear out coupons for example.

Currie Group also supplies a wide range of Horizon folders, suitable for every size and speciality of printing enterprise.

We have models from 560 to 760 wide, all equipped with intelligent automation. The operator can adjust the settings by inputting the paper size and fold pattern on the colour touch screen. It takes only a couple of minutes to finish a changeover from 16-page B-1 format signatures to 16-page B-2 format signatures.

Every document finishing line also requires a collator to arrange pages in proper order. Horizon collators have a reputation for being fast and accurate. They can operate as a stand-alone piece of equipment or can link to Horizon stitcher/trimmers for automated feeding of uncollated sets. Year after year they have maintained their popularity, whether 10-bin rotary feed VAC-1000 or the 15-bin friction feed SAC-150.

It’s important that collators are able to be part of an automated finishing line no matter how many towers are used.

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter