Label press developer Rapid hopes its new XL220 digital label press – which boasts less than a metre of material waste in set up – will impress buyers looking for a mid-level colour digital labeller when it goes on show at Ipex, at the end of the month. Rapid looks set to be the sole Aussie supplier at the London expo, and though it will not be bringing the XL220 with it in the flesh (with the first unit soon to be installed with a NSW buyer), it hopes to seal the deal with a prospective European buyer and attract a handful of new customers at the show. Nick Mansell, general manager of the family-owned business, says the machine aims to fill a niche in the market between entry level digital presses and high-end machines – with less waste as the extra sweetener for cost-conscious converters.

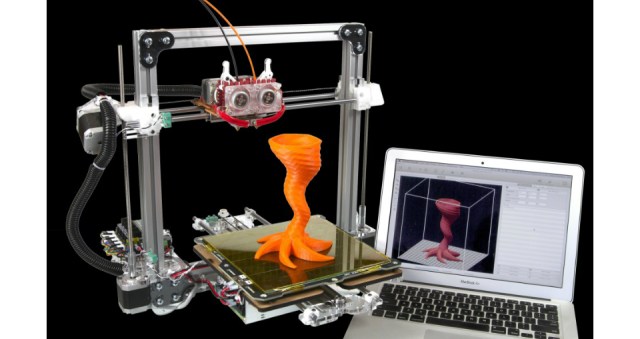

Proud engineer: Nick Mansell, general manager of Rapid, shows off less than a metre of start up waste on the XL220

He says, “We are trying to bridge the gap between the big end of town – the flexo presses and offset machines and high-end digital presses like your Indigo-type lines – and the short run entry-level digital. There seems to be nothing in that middle market, it jumps from around $20,000 up to half a million.” As well as its first Australian sale and interest in Europe, Rapid is also currently courting a buyer for the XL220 in the US. The machine features Memjet technology, often integrated for ultra short run machines, but with the XL220 Rapid aims for longer production capability with quality digital print – available for less than $100,000. Print resolution is 1,600 x 1,600 dpi, print length 1,799mm and it runs at speeds from 18mpm at lower resolution, 9mpm at max. Available options include UV flexo coating, hot foiling and cold foiling. The Memjet is restricted to A4 size, but Mansell says any one of the company’s finishing modules can work inline or offline with other larger digital presses in the marketplace. He tells AP, “The finishing system has taken our ingenuity and 24 years of experience working with semi-rotary technology to go from presses that take 15 to 20 metres of set up material waste down to as little as one metre to start producing quality commercial labels. “One of the strengths of the Memjet technology we are using in this machine is that it feeds at the start of the web and prints the first label at the leading edge, you don’t have to feed a metre or more of the material through the engine before printing. That is the point of difference for the XL range. “We have a diecutter, flexo, cold foiling units and other finishing modules all coming into the family over the coming months.”

Rapid says it has tried to minimise and control set up times by locking in settings during prepress, meaning the operator does not have to make large adjustments on the machine. Mansell says, “This means we may be able to put an XL220 into certain industries that do not traditionally have trained printers onsite.” The company is also looking to emphasise the machine’s environmental features, with a small footprint and low power consumption – and a modular design that means customers can swap in or out the features they need. Rapid takes pride in this flexibility as one of its key strengths; Mansell says, “Our tagline for the XL220 – small where it matters, big where it counts – is in some ways also how we think about Rapid as a company. We are small enough to be flexible, but we have the experience to make a product that can go out and compete on the world stage.” Rapid founder Bruce Mansell is still recovering after his car accident last September; the family says though he has lost his eyesight he is in mostly good spirits and is staying positive. Nick Mansell says, “He is coming in about two and a half days to the factory a week, to keep an ear on us. He came in to check out the XL220 the other day, he said he’d like to be able to say it looks like a fantastic piece of kit – but it definitely feels like it.”

Comment below to have your say on this story.

If you have a news story or tip-off, get in touch at editorial@sprinter.com.au.

Sign up to the Sprinter newsletter